Drive wheel assembly, crawler drive mechanism of crane and matching adjustment method thereof

A driving mechanism and driving wheel technology, used in tracked vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as teeth gnawing, and achieve the effect of improving wear resistance, avoiding teeth gnawing, and delaying wear time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

[0036] The embodiment of the present invention provides a drive wheel assembly that is easy to maintain, has a wide application range, and is low in cost, a crawler drive mechanism of a crawler crane provided with the drive wheel assembly, and a maintenance method for the drive wheel assembly.

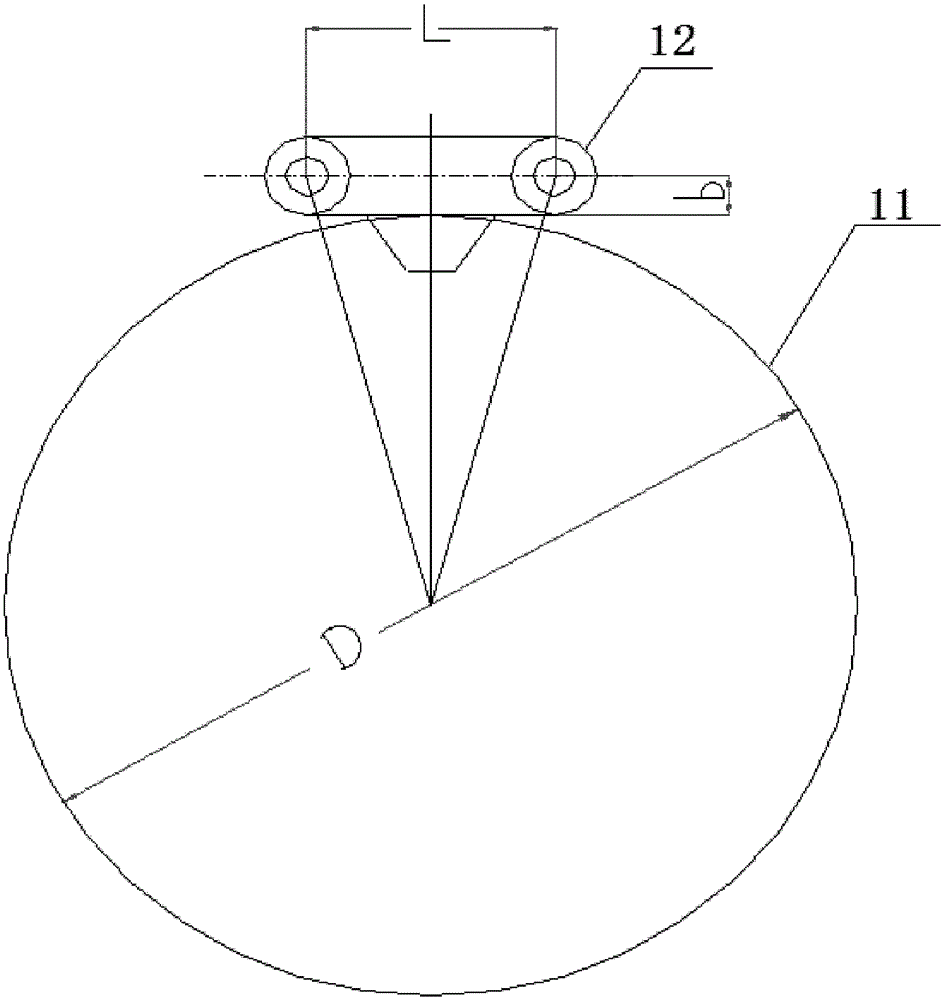

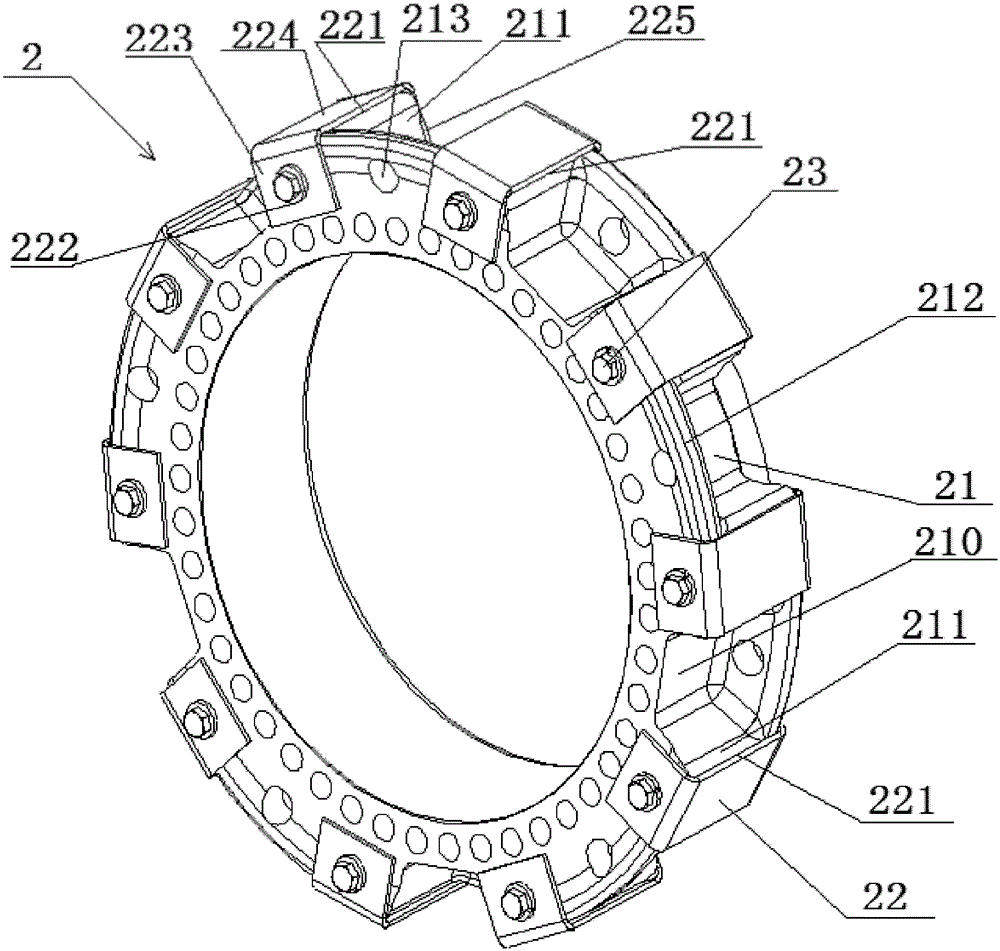

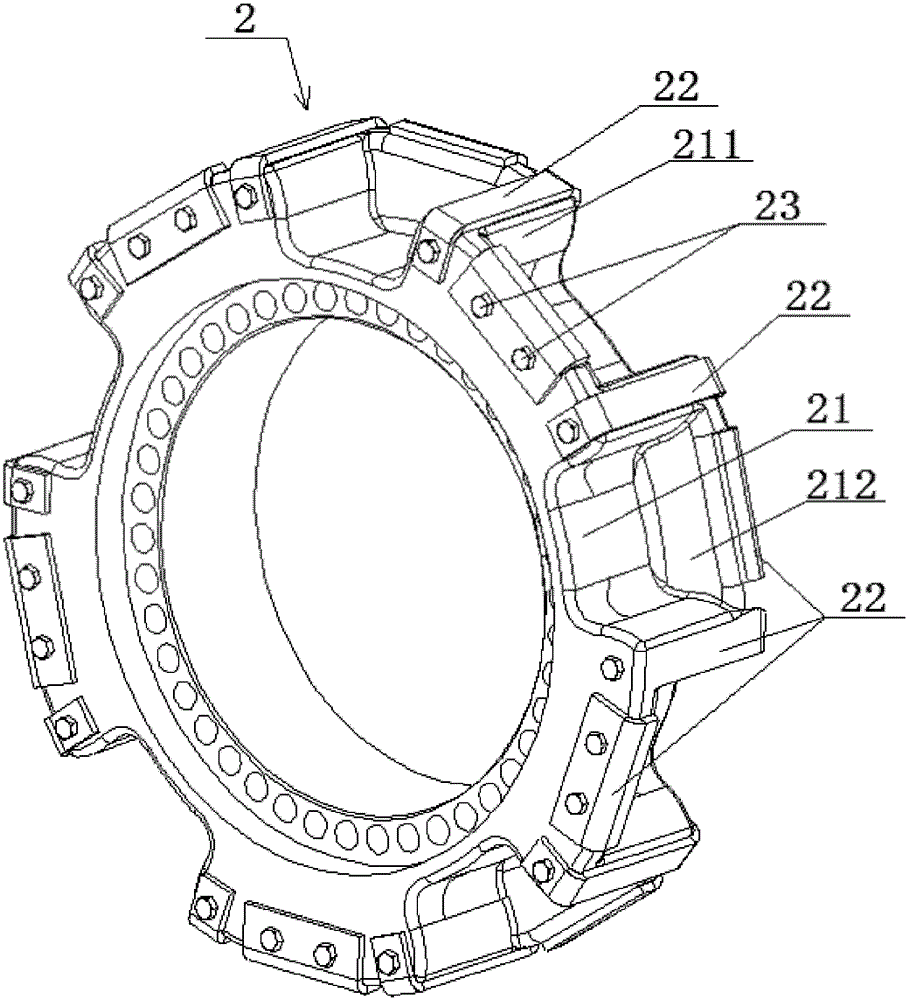

[0037] Such as figure 2 with image 3 As shown, the driving wheel assembly 2 provided by the embodiment of the present invention includes a driving wheel 21 and a wear-resistant protective pad 22 made of wear-resistant material, wherein:

[0038] The inner surface of the wear protection pad 22 is provided with a recessed portion 221, and more than two gear teeth 211 are distributed on the outer surface of the driving wheel 21, and there is also a circumferential direction along the driving wheel 21 between adjacent gear teeth 211 A connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com