Wind turbine blade with split winglet at apex

A wind turbine blade and tip technology, applied in the field of wind power generation, can solve the problems of dispersing the intensity of blade tip vortex, weakening the induced influence of blade tip vortex, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

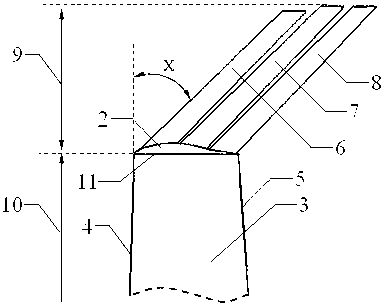

[0028] Figure 1 ~ Figure 3 For utilizing the shape of embodiment one blade of the present invention. The length of the main body of the blade is 4.5 meters, the airfoil of the main blade is S809 airfoil, the relative thickness of the airfoil is 21%, the chord length of the tip 11 of the main blade is 0.21 meters, and the projected length 9 of the winglet 1 on the centerline of the main blade is 0.225 rice.

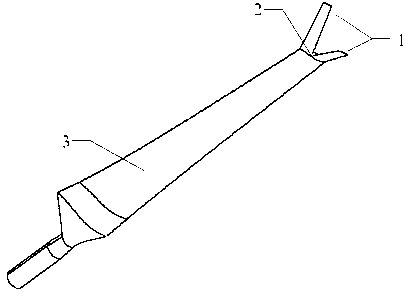

[0029] refer to figure 1 , is the overall perspective view of Embodiment 1. The split winglet is composed of a winglet 1 and a root connecting section 2 which connects the winglet 1 with the main blade 3 .

[0030] refer to figure 2 , is the front view of Embodiment 1. The winglet 1 is composed of three sub-wings, from the leading edge 4 to the trailing edge 5 are the front sub-wing 6 , the middle sub-wing 7 and the rear sub-wing 8 . The projection length 9 of the winglet 1 on the centerline of the main blade is 5% of the length 10 of the main blade. The three sub...

Embodiment 2

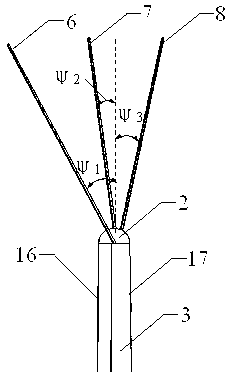

[0033] Figure 4 ~ Figure 6 For utilizing the shape of embodiment two blades of the present invention. The length of the main blade is 4.5 meters, the tip of the main blade is S809 airfoil, the relative thickness of the airfoil is 21%, the chord length of the tip 11 of the main blade is 0.21 meters, and the projected length 9 of the winglet 1 on the centerline of the main blade is 0.675 rice.

[0034] refer to Figure 4 , is the overall perspective view of the second embodiment. The split winglet is composed of a winglet 1 and a root connecting section 2 which connects the winglet 1 with the main blade 3 .

[0035] refer to Figure 5 , is the front view of the second embodiment. Winglet 1 is made up of two sub-wings, and from leading edge 4 to trailing edge 5 is successively front sub-wing 6 and rear sub-wing 8 . The projection length 9 of the winglet 1 on the centerline of the main blade is 15% of the length 10 of the main blade. The shape of the two sub-wings is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com