Inflatable wing based on oblique-swept gas beams

An air beam and airfoil technology, applied in the field of inflatable wings, can solve the problems that the design method of rigid airfoil is difficult to apply, difficult to meet the needs of refined application, serious aeroelastic effect, etc., so as to improve flight economy and flutter performance. Improve and reduce the effect of induced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

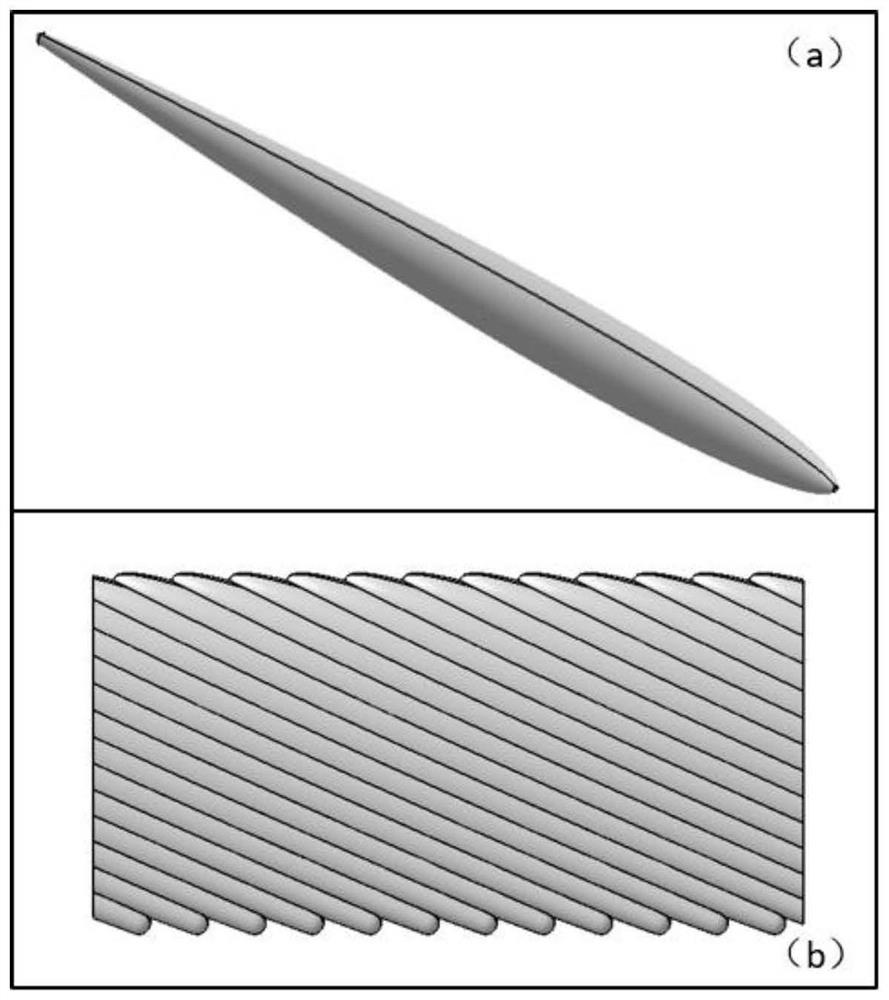

[0071] In this embodiment, based on the design ideas described in the content of the invention, a forward-swept air beam inflatable wing based on a symmetrical airfoil is constructed, and compared with the traditional braided inflatable wing, its geometric parameters and the built model are as follows Table 1 shows.

[0072] Table 1

[0073]

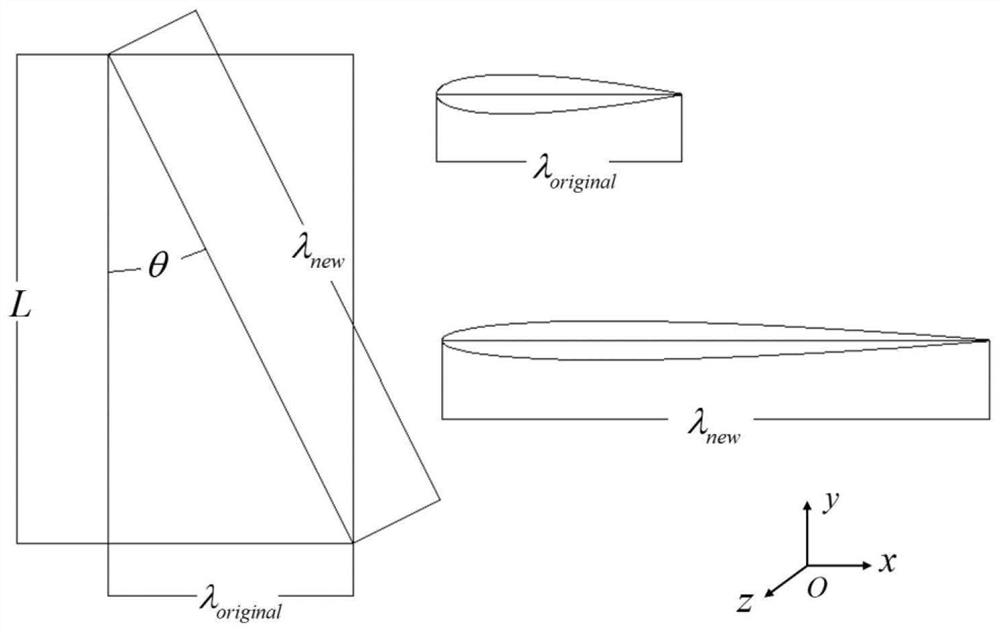

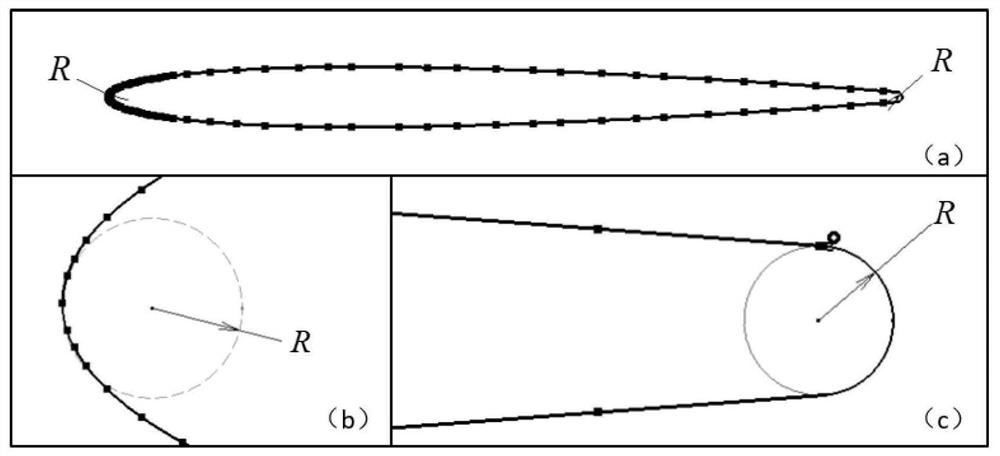

[0074] Among them, the model of the forward-swept air beam inflatable wing based on the symmetrical airfoil NACA0016 is constructed, and the specific implementation steps are as follows: 1. Determine the basic parameters of the inclined-sweep air beam inflatable wing, including the basic airfoil of the inflatable wing, the chord length λ original , spread length L and slope-swept air beam

[0075] Sweep angle θ and chamber spacing x. In this embodiment, the symmetrical airfoil NACA0016 is used as the basic airfoil, and the chord length λ is selected original =405.5mm, length L=802.9mm Rectangular wing is taken as an example, the sl...

Embodiment 2

[0091] In this embodiment, based on the design idea described in the content of the invention, a kind of asymmetrical airfoil based on the swept-swept air beam inflatable wing is constructed, and compared with the traditional braided inflatable wing, its geometric parameters and the built model As shown in Table 4.

[0092] Table 4

[0093]

[0094] Among them, based on the asymmetrical airfoil NACA4418, the model of the swept-swept air beam inflatable wing is established, and the design idea is slightly different from that based on the symmetrical airfoil. The specific steps are as follows.

[0095] 1. Determine the basic parameters of the slanted-swept air beam inflatable wing, including the basic airfoil and chord length λ original , splayed length L and the angle θ of the slanted air beam and the spacing x of the air chamber. In this embodiment, NACA4418 is used as the basic airfoil, and the sweep angle θ of the air spar is swept back at 24°, and the rest of the basic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com