Petroleum pipeline with taper structures

A technology of petroleum pipelines and cones, which is applied in the field of petroleum pipelines with cone structures, and can solve the problems of poor durability of sealing measures and complex sealing structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

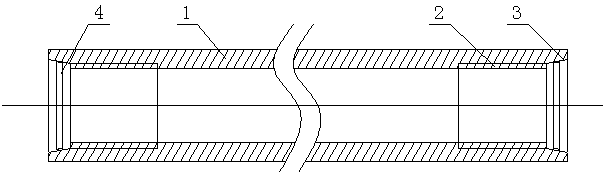

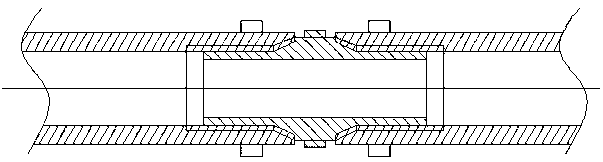

[0013] Such as Figure 1-2 As shown, a petroleum pipeline with a tapered mouth structure described in the embodiment of the present invention includes a body 1 with a circular tubular structure. Internal threads 2 are provided at both ends of the body 1, and cones are provided on the outside of the internal thread 2. mouth structure 3, the taper of the cone mouth structure 3 is greater than 1 / 5, the minimum inner diameter of the cone mouth structure 3 is equal to the diameter of the screw tooth base of the internal thread 2, and the inner surface of the cone mouth structure 3 is a smooth surface , making it easy to contact and seal with the gel seal structure.

[0014] The internal thread 2 is a rectangular structural thread.

[0015] An arc-shaped annular protrusion 4 is provided in the middle of the cone structure 3, and the minimum inner diameter of the annular protrusion 4 is smaller than the diameter of the screw tooth base of the internal thread 2 to prevent it from int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com