Partition plate assembly for indoor space division

A clapboard assembly and interior space technology, applied to building components, walls, buildings, etc., can solve the problems of increasing medical staff's infection of infectious diseases, simple isolation membranes cannot be sealed, and it is difficult to maintain their own shape, so as to prevent airflow from interfering with each other Flow, excellent sealing performance, avoid falling off or deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

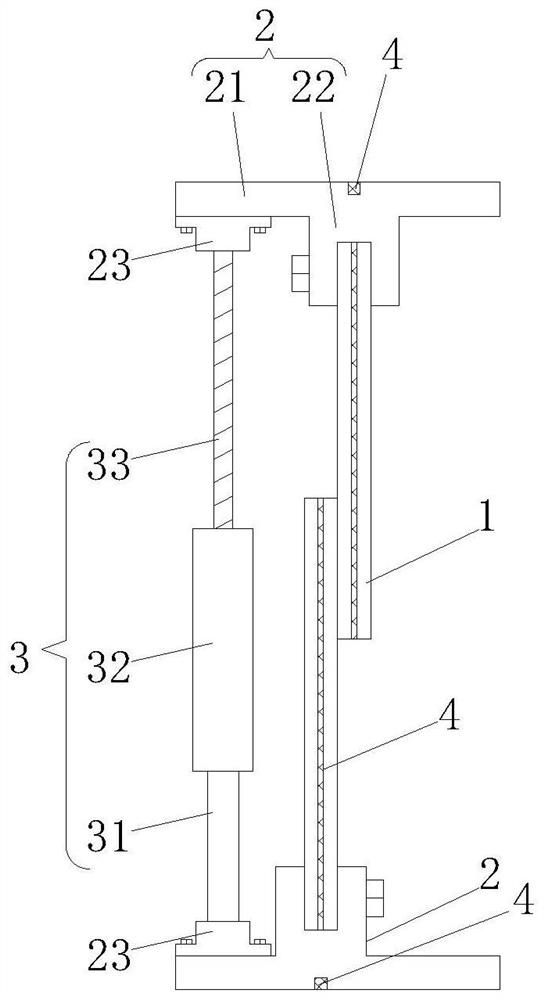

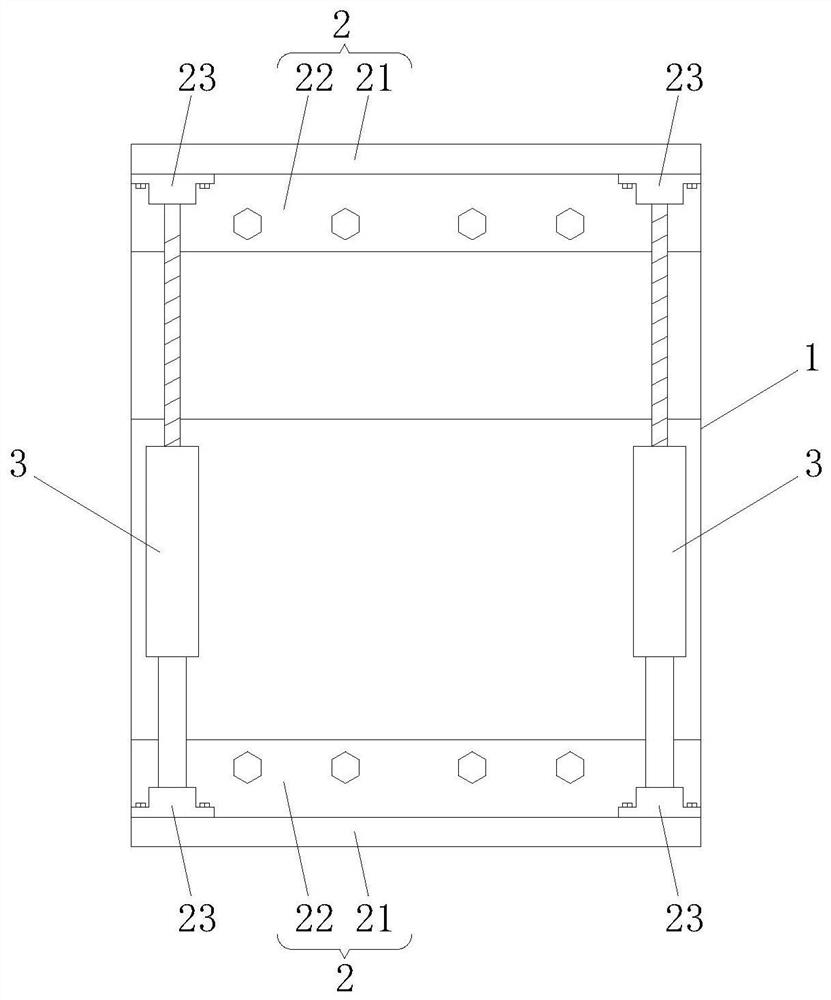

[0035] A partition assembly for indoor space division, such as figure 1 and figure 2 As shown, it includes a telescopic plate 1, a fastening layer 2, a lockable telescopic rod 3 and a sealing strip 4.

[0036] The expansion plate 1 is generally rectangular, and it includes at least two sections of the plate, and all adjacent plates are movably connected along the same straight line. For example, the expansion plate 1 in this embodiment includes two sections of the plate. Arranged in a straight line, it can be freely stretched and adjusted according to different indoor floor heights.

[0037] Fastening bead 2 is configured with two, and fastening bead 2 is elongated, and the two ends of above-mentioned expansion plate 1 telescopic direction (height direction) can be detachably fixedly connected with a fastening bead 2. Moreover, the fastening bead 2 is arranged along the stretching direction of the end, and the two ends of the fastening bead 2 are respectively aligned with t...

Embodiment 2

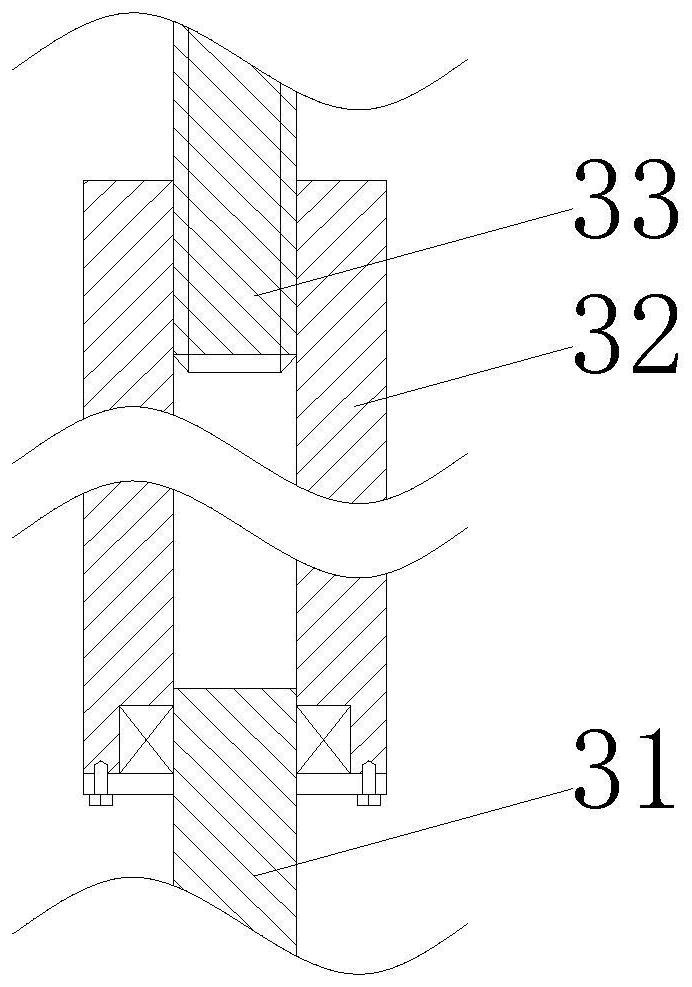

[0046] The difference between it and Embodiment 1 is: in this embodiment, if Figure 4 As shown, the lower rod 31 is set to be a hollow structure, and the inner diameter of the lower rod 31 is greater than the diameter of the upper rod 33, so that the upper rod 33 can be accommodated when the lockable telescopic rod 3 shrinks, thereby reducing the length of the middle casing 32. It is not used to accommodate the upper pole 33, so as to reduce the overall size of the bulkhead assembly during transportation and storage.

Embodiment 3

[0048] The difference between it and Embodiment 1 is: in this embodiment, if Figure 5 As shown, a plurality of operating rods 5 are hinged on the circumferential side wall of the middle section sleeve 32, and one end of the operating rod 5 is hinged on the middle section sleeve 32, and between each operation rod 5 and the middle section sleeve 32 All are connected with return extension spring 6. Such arrangement makes it possible to save energy through the operating rod 5 when the middle segment sleeve pipe 32 needs to be rotated, and after the operation is completed, the return tension spring 6 can reset the operating rod 5 into a folded shape; in addition, since each operating rod 5 is independently Folding, so that in the process of rotation, only one operating rod 5 needs to be unfolded, and the other operating rods 5 can be folded, so as to prevent the operating rods 5 from colliding with the telescopic plate 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com