Calibration Method of Gamma Value in Phase Measurement System

A technology of phase measurement and calibration method, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of unstable phase error distribution, small depth of field of projectors, unable to completely eliminate phase errors, etc. effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

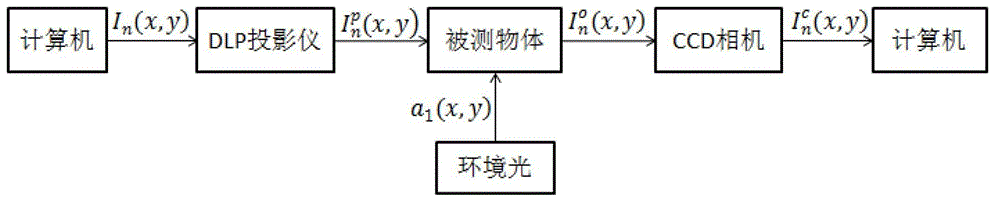

[0024] In a typical fast phase measurement system, the process of taking a grating image is (eg figure 1 ):

[0025] 1) The computer generates the ideal grating image I with sinusoidal distribution of light intensity n (x, y), and send it to the projector through the VGA signal;

[0026] 2) The projector projects a gamma-distorted raster image to the measured object;

[0027] 3) The surface of the measured object will be projected onto the grating image on the surface of the object and ambient light a 1 (x, y) reflected into space;

[0028] 4) The CCD camera captures the light reflected from the surface of the measured object to obtain the final grating image and stored in the computer.

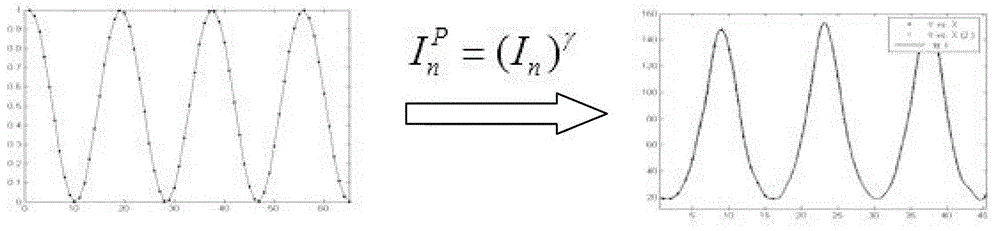

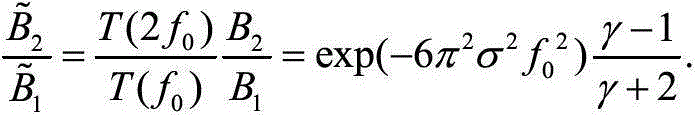

[0029] The gamma deformation in the second step of the above process will cause the nonlinear transformation of the raster image grayscale (such as figure 2 ), thus causing serious phase errors, which in turn affect the measurement accuracy of the phase measurement system. Based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com