A permanent magnet translational meshing motor

A motor, translational technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of increasing the driving device components and weight, impracticality, complex structure, etc., to improve power density, improve efficiency, and avoid eddy currents The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

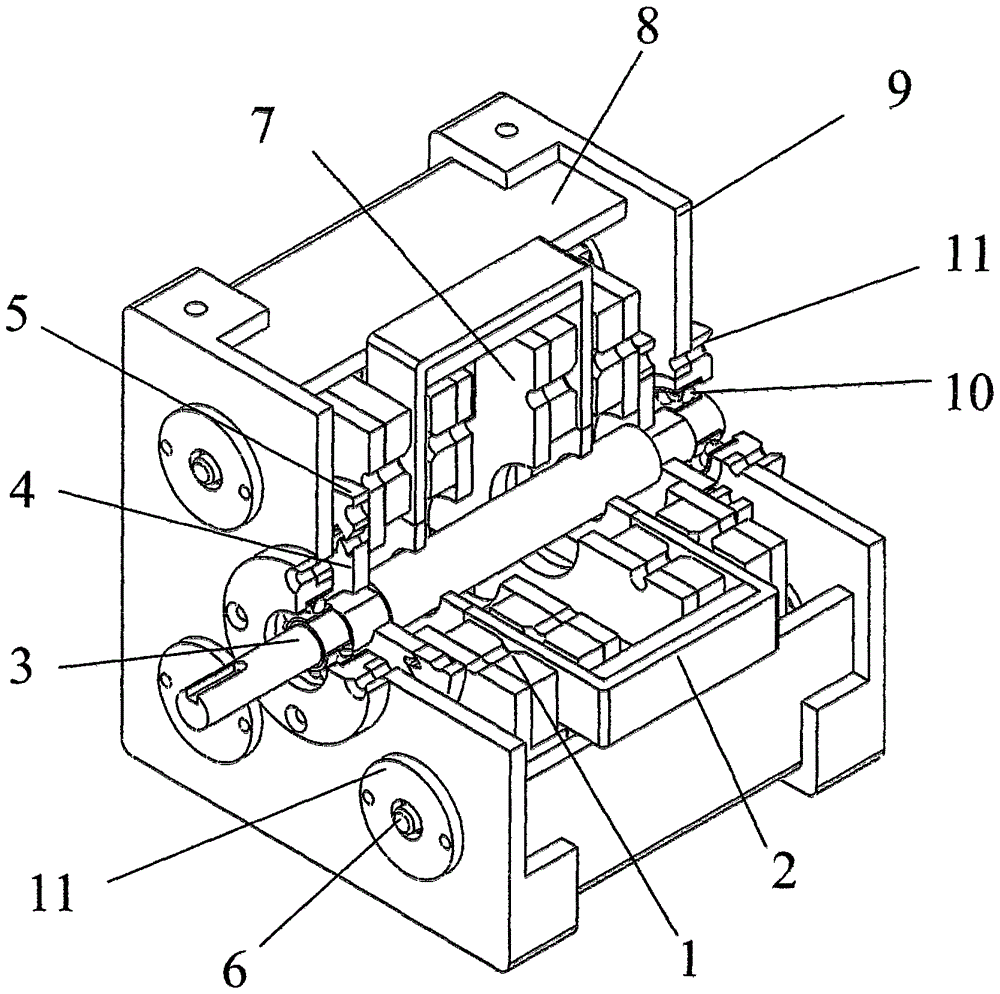

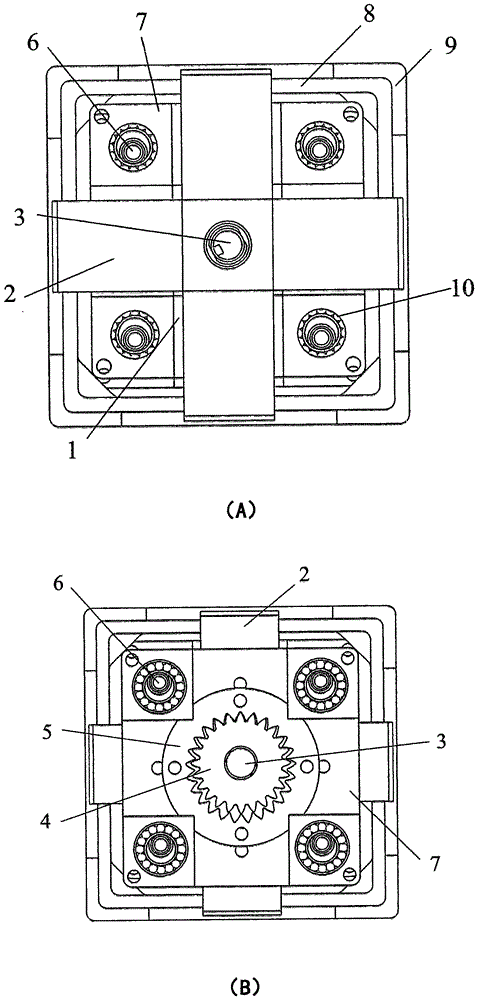

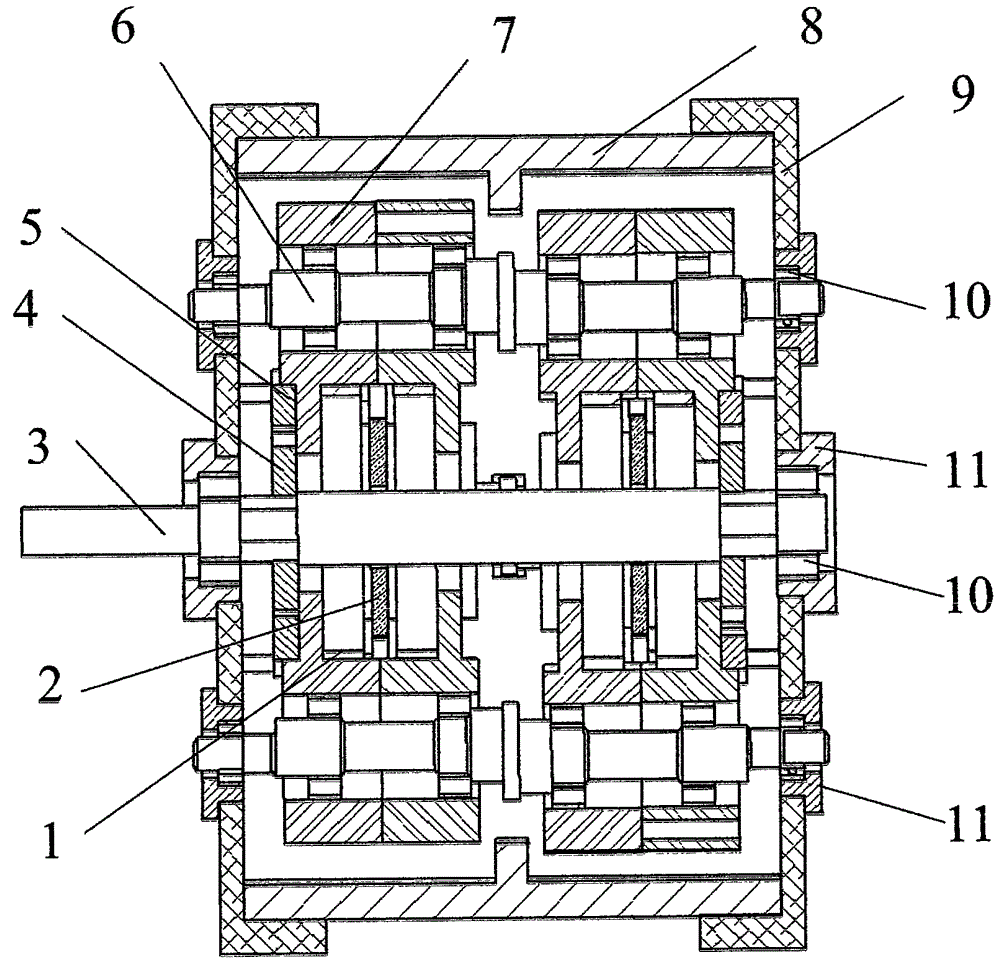

[0038] see Figure 1 to Figure 13 , introduces the structural composition of the permanent magnet translational meshing motor of the present invention: it integrates the motor and the reducer to simplify the mechanical transmission mechanism, and has certain self-locking and braking functions and direct output of low speed and high torque. electric motor. The electric motor is provided with: a winding 2, a permanent magnet 1, an inner ring gear 5 and an outer gear 4 of the gear reducer, a rotor fixing frame 7, and the supporting parts are a casing 8 and an end cover 9. Wherein, every eight permanent magnets 1 together with two rotor fixing frames 7 form a rotor, and the motor has two identical rotors in total. The external gear 4 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com