Method for continuous extrusion compounding of layered composite electrical contact materials

An electrical contact material, layered composite technology, used in metal extrusion control equipment, metal extrusion, metal processing equipment, etc., to achieve high dimensional precision control, good interface bonding quality, and good finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In Example 1, the operation steps for preparing mosaic-type layered composite elements using continuous extrusion composite technology are as follows:

[0026] I), the material composition of layered composite electric contact

[0027] The material composition of the layered composite electrical contact is mainly pure silver and pure copper, of which the width and thickness of the silver strip is 4mm×1mm, and the width and thickness of the special-shaped copper strip is 10mm×4mm.

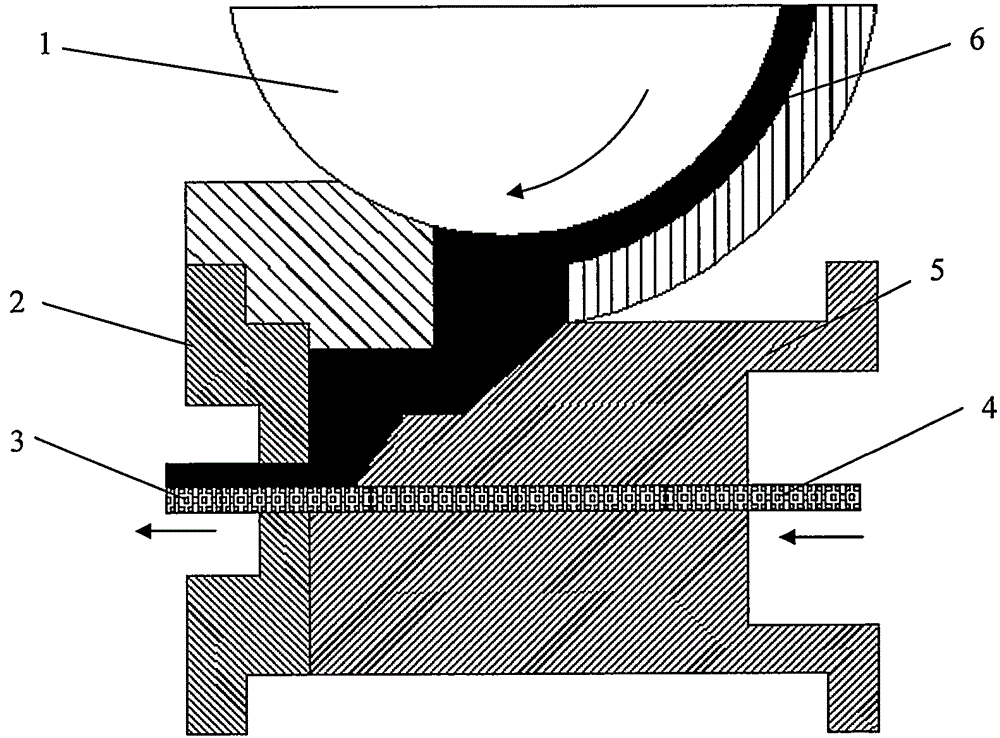

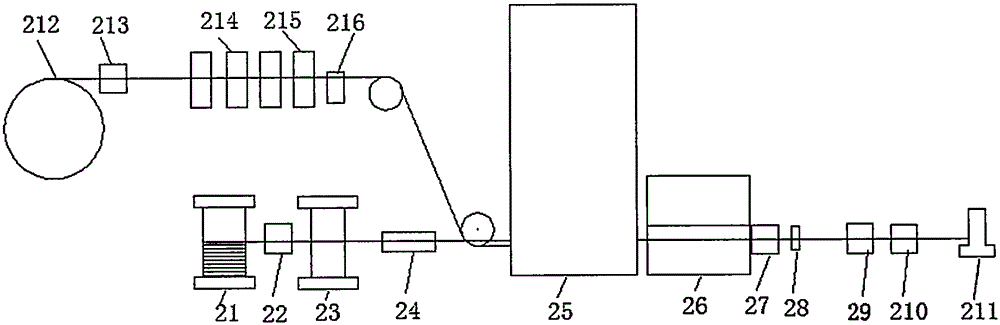

[0028] II), continuous extrusion compound equipment and mold

[0029] The contact element is a double-layer mosaic composite, so the layered composite electrical contact material is prepared by using a single-wheel continuous extrusion composite machine. The extrusion die material designed according to the contact element is H13 steel (ie 4Cr5MoSiV1), and the main parameters of the die structure are as follows:

[0030] diversion angle

Composite deformation zone length

Cali...

Embodiment 2

[0038] The difference from Example 1 is that this Example 2 uses silver-based composite electrical contact material AgNi10 and pure copper metal as raw materials, and performs partial surface-to-surface composite through continuous extrusion composite to prepare a layered composite contact material.

[0039] The basic operation steps for the preparation of the layered composite electrical contact in Example 2 are as follows:

[0040] I), the material composition of layered composite electric contact

[0041] The material composition of the layered composite electrical contact is mainly AgNi10 and copper. The thickness of the AgNi10 strip is 4mm×2mm, and the width of the copper strip is 10mm×5mm. The shape and size of the AgNi10 and copper strip are relatively accurate, and the surface cleanliness is also high. better.

[0042] II), continuous extrusion compound equipment and mold

[0043] The contact is partially double-layered. Therefore, the layered composite electrical co...

Embodiment 3

[0052] The difference from Example 1 is that in Example 3, silver alloy and iron metal are used as raw materials, and surface-to-surface compounding is carried out by continuous extrusion compounding to prepare a layered composite contact material.

[0053] The basic operation steps for the preparation of the layered composite electrical contact in Example 3 are as follows:

[0054] I), the material composition of layered composite electric contact

[0055] The material components of layered composite electrical contacts are mainly silver alloy and iron metal, in which the width and thickness of the silver alloy strip is 10mm×2mm, and the width and thickness of the iron strip is 10mm×5mm. The shape and size of the silver alloy and iron metal strips are relatively Accurate, surface cleanliness is also better.

[0056] II), continuous extrusion compound equipment and mold

[0057] The contact is double-layered. Therefore, the layered composite electrical contact material is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com