Cotton opening and cleaning roller

A technology of cleaning roller and cotton, applied in the direction of fiber opening and cleaning machine, etc., can solve the problem of incomplete removal of impurities, etc., and achieve better opening effect and facilitate falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

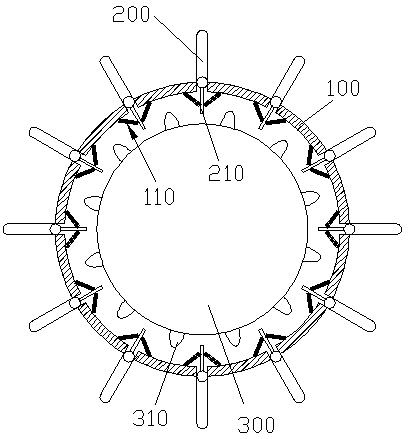

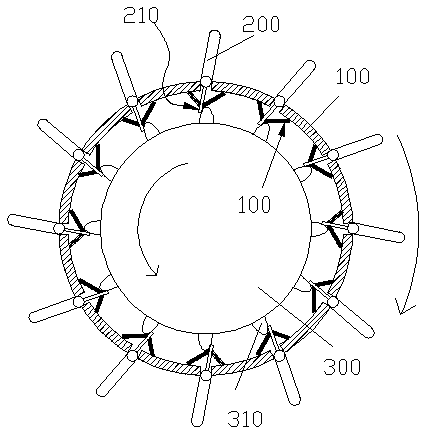

[0018] refer to figure 1 , in this embodiment, the cotton cleaning roller includes a driver-driven hollow roller 100 and a housing that closes the hollow roller 100, and beaters 200 are evenly distributed on the body of the hollow roller 100, and the The beater 200 is hinged with the cylinder body, the root of the beater 200 is provided with a paddle 210, and the paddle 210 is connected with an elastic member to maintain the angle of the paddle 210, and the hollow roller 100 is provided with a cycle Toggle the toggling member of the plectrum.

[0019] For the cotton cleaning roller mentioned above, the elastic member is the spring 110 arranged on both sides of the plectrum 210. When the spring 110 performs elastic movement, there is no friction of the hydraulic rod, so it has high stability.

[0020] In the above-mentioned cotton opening and cleaning roller, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com