Biomass gasification furnace convenient for air inlet and ash discharge

A biomass and gasifier technology, applied in the field of household stoves or stoves, can solve the problems of difficulty in ensuring free vibration of a vibrating screen, limitation of the total area of an ash discharge pipe, complicated installation process, etc., so as to shorten the ignition time and facilitate ash discharge. Slag, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

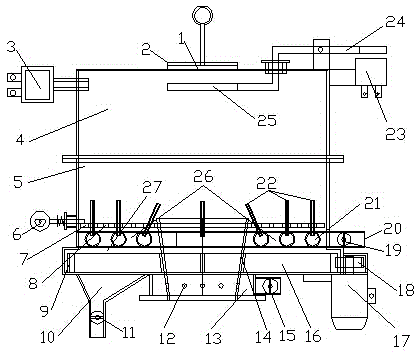

[0039] figure 1 middle;

[0040] The fire closing plate 1 is movably connected with the fire outlet 2, the fire outlet 2 is connected with the upper part 4 of the furnace, the igniter 3 is fixedly connected with the side wall of the upper part 4 of the furnace, the upper part 4 of the furnace is connected with the lower part 5 of the furnace, and the material level sensor 23 is connected with the upper part of the furnace 4 connected, the material level sensing rod 24 is flexibly connected with the furnace upper part 4, and the material level sensing rod 24 is connected with the material level sensing plate 25.

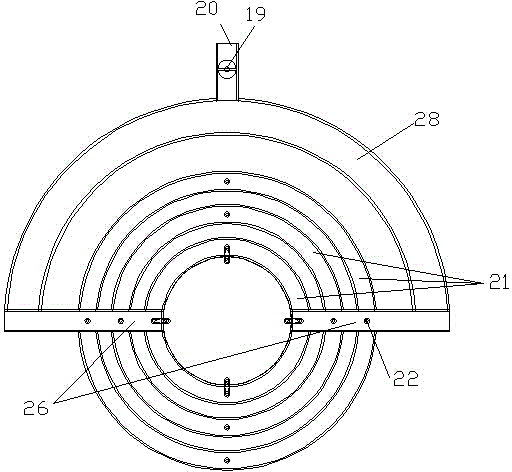

[0041] The annular air duct air inlet 20 is connected with the annular air duct valve 19, the annular air duct valve 19 is connected with the annular air duct 21, the annular air duct 21 is fixedly connected with the furnace inner bottom of the furnace lower part 5, and the annular air duct 21 has a gap with the vibrating screen 7 Connected, the vibrating screen 7 is...

Embodiment 2

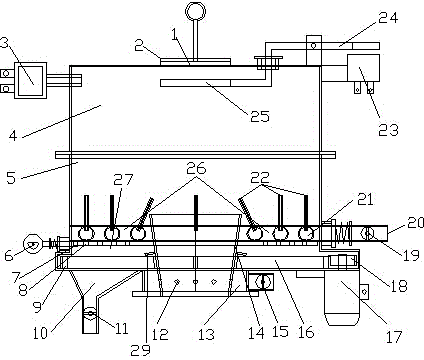

[0044] figure 2 middle;

[0045] Its structure is that the annular air duct 21 is movably connected with the lower part 5 of the furnace, the annular air duct 21 is fixedly connected with the vibrating screen 7, the vibrating screen 7 is under the annular air duct 21 and is movably connected with the lower part 5 of the furnace, and the vibrator 6 is fixed with the vibrating screen 7 Connected, the vibrator 6 is movably connected with the lower part 5 of the furnace. That is, the annular air duct 21 and the vibrating screen 7 vibrate simultaneously. The ash retaining flange 29 is arranged on the feed pipe wall, and the ash retaining flange 29 is above the rotating connection position between the ash scraping wheel 16 and the feed pipe wall, and is used to block the ash from directly entering the rotating connection position from above to reduce jamming. death phenomenon.

[0046] In the two structures of the above schemes, since the outer surface of the annular air duct 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com