A Calculation Method of Functional Dimensions of Holes in Parts

A calculation method and a technology of part holes, which are applied in calculation, special data processing applications, instruments, etc., can solve the problems that the calculation results are difficult to achieve accurate solutions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

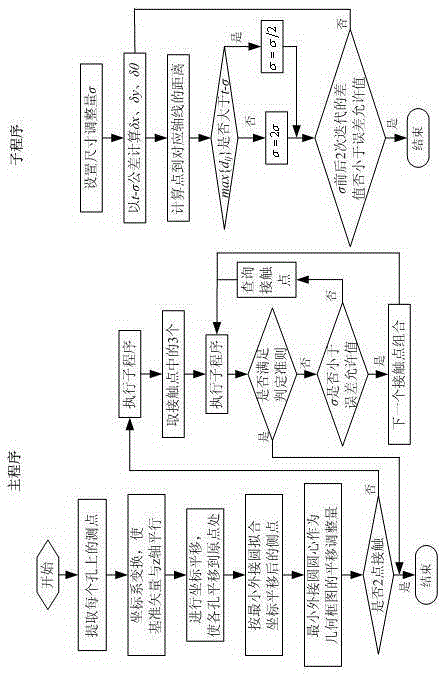

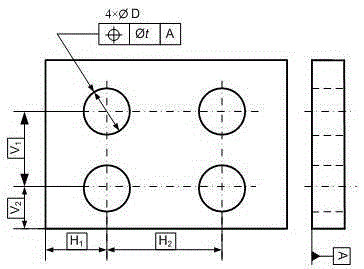

[0059] A calculation method for the functioning dimension of a hole system of a part, which is used to calculate the minimum circumscribed dimension of a hole system, as attached figure 1 As shown, it mainly includes the following steps:

[0060] Step 1: Place the measured part on the measurement platform, and extract a series of measuring points on each hole; obtain the ideal design position of each hole according to the drawing information - the theoretical coordinates of the fixed point on the axis of each hole.

[0061] Step 2: On the datum plane, extract the measurement points of the datum features, and apply the minimum area method to fit the datum plane to obtain the normal vector of the datum plane; perform coordinate transformation to make the coordinate system z The axis is parallel to the normal vector of the datum plane; at the same time, the measuring points on each hole are also subjected to the same coordinate transformation. After the coordinate transformation...

Embodiment 2

[0083] A calculation method for the functioning dimension of a hole system of a part, which is used to calculate the maximum inscribed size of a hole system, as attached figure 1 As shown, it mainly includes the following steps:

[0084] Step 1: Place the measured part on the measurement platform, and extract a series of measuring points on each hole; obtain the ideal design position of each hole according to the drawing information - the theoretical coordinates of the fixed point on the axis of each hole.

[0085] Step 2: On the datum plane, extract the measurement points of the datum features, and apply the minimum area method to fit the datum plane to obtain the normal vector of the datum plane; perform coordinate transformation to make the coordinate system z The axis is parallel to the normal vector of the datum plane; at the same time, the measuring points on each hole are also subjected to the same coordinate transformation. After the coordinate transformation, the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com