Heat forging press

A press and hot forging technology, which is applied in the improvement field of hot forging presses, can solve problems such as hidden safety hazards, influence on the use of presses, insufficient rigidity and connection strength, etc., to reduce thermal deformation and elastic deformation, reduce overall height, The effect of improving connection stability and device reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

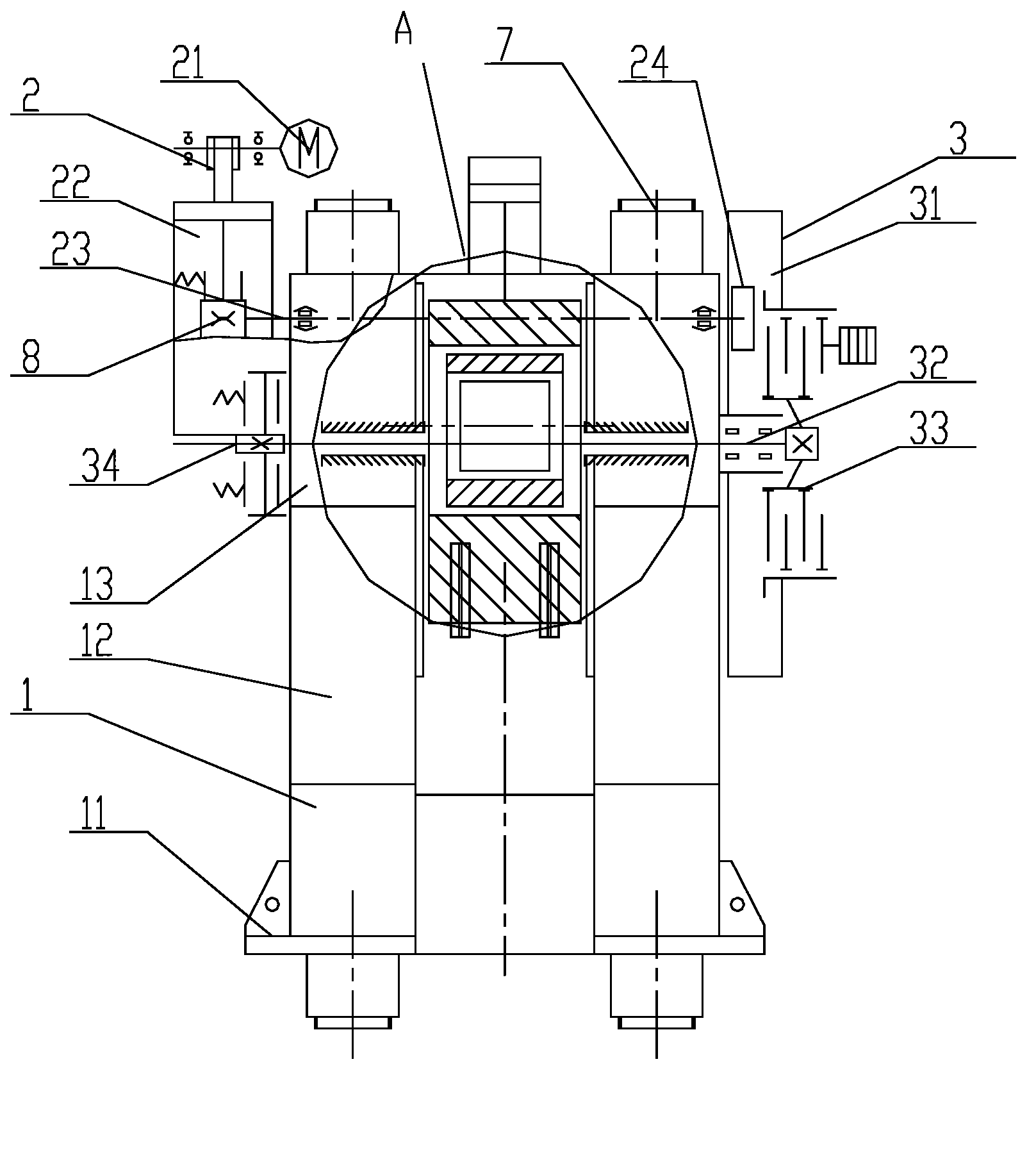

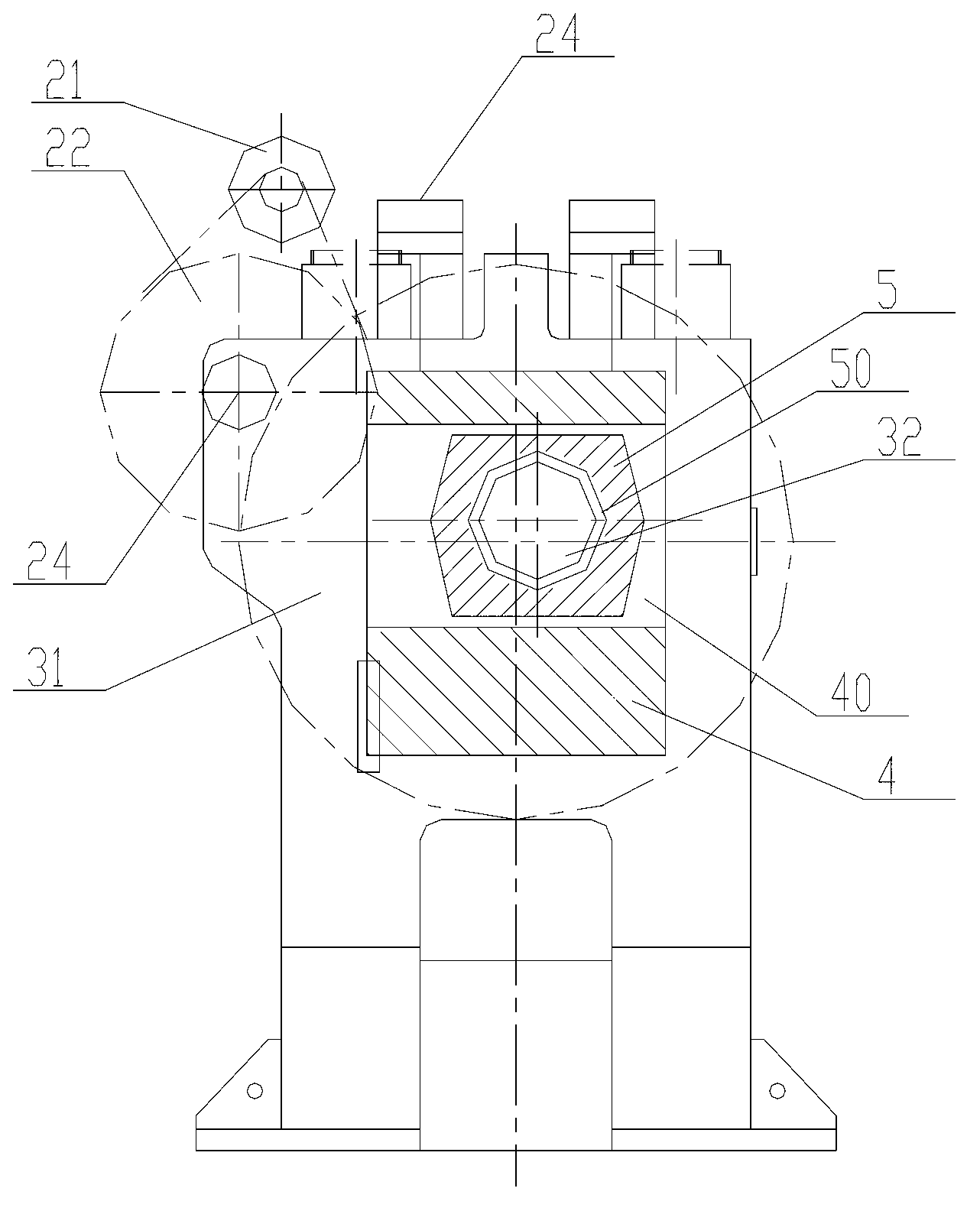

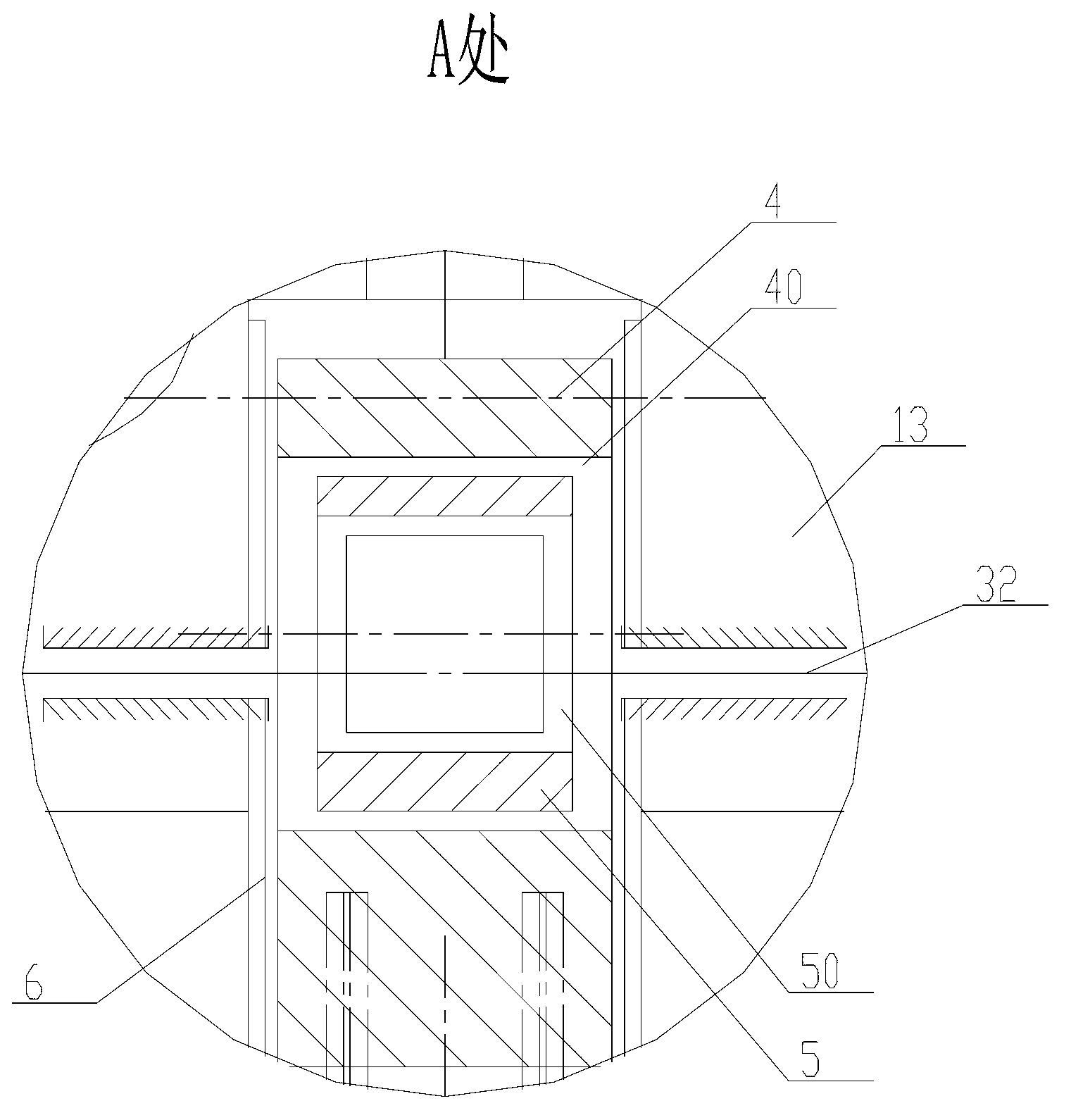

[0038] The present invention as Figure 1-5 As shown, it includes a fuselage 1 composed of a base 11, left and right columns 12, and a beam 13. A flywheel mechanism 2 for a primary deceleration effect and a large flywheel mechanism for a secondary deceleration effect are respectively provided on the two outer sides of the beam. gear mechanism 3,

[0039] The flywheel mechanism 2 includes a main motor 21, a flywheel 22, a transmission shaft 23 and a pinion 24. The transmission shaft 23 runs through the crossbeam 13 from the left and right directions, is movably connected on the crossbeam 13, and is located at the center of the fuselage 1. In the back position, one end of the transmission shaft 23 facing the flywheel mechanism 2 is connected to the flywheel 22, and one end facing the large gear mechanism 3 is connected to the pinion gear 24;

[0040] The large gear mechanism 3 includes a large gear 31, a crankshaft 32, a clutch 33 and a brake 34. The crankshaft 32 runs through ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap