A feeder for bagging powder

A feeder and powder technology, which is applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of antimony trioxide loss, environmental pollution, and affecting workers' health, so as to reduce the loss of powder and reduce environmental pollution , Powder bagging is simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

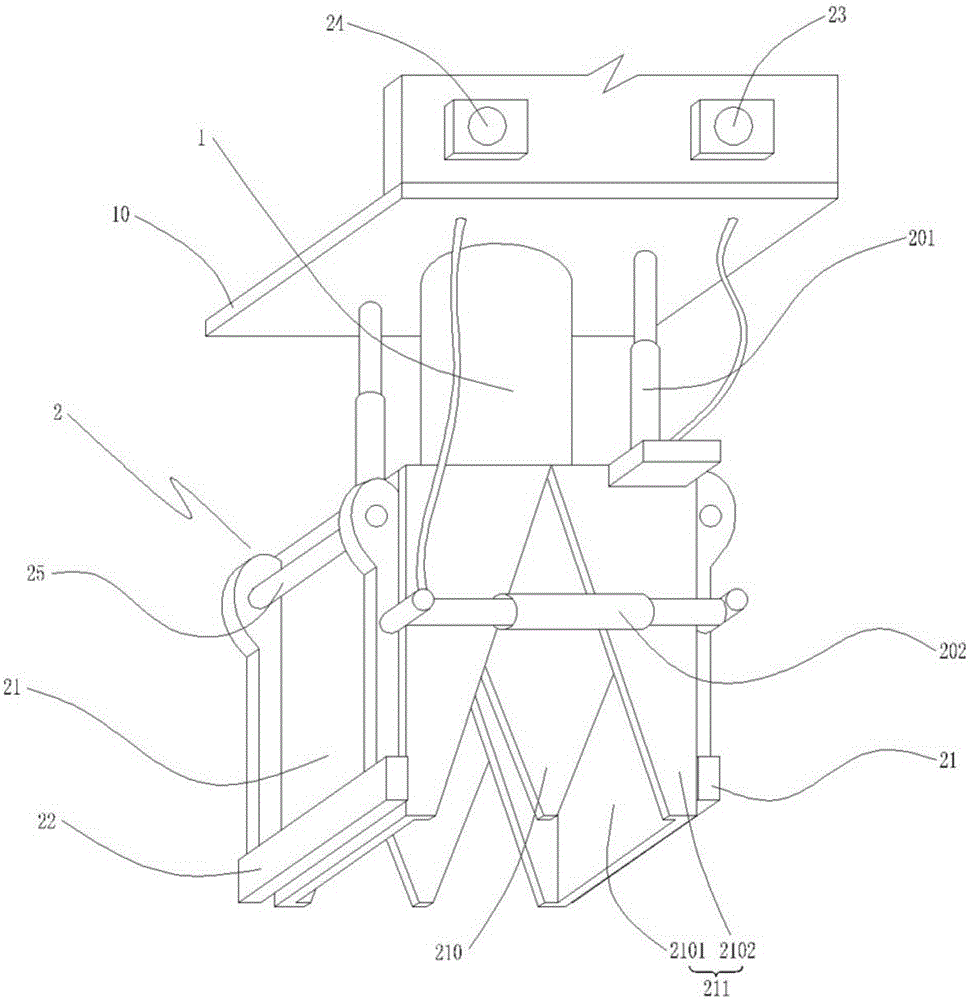

[0015] This embodiment provides a feeder for powder bagging, please refer to figure 1 , the feeder includes: a feeding tube 1 and a bag clamping device 2 , the bag clamping device 2 can be arranged on the periphery of the feeding tube 1 up and down along the feeding tube 1 . In this way, the powder is conveyed from the feeding tube 1, and the bag used to hold the powder is clamped on the bag clamping device 2, and the powder is packed into the bag at the bag clamping device 2, so that the powder bagging process It is convenient and simple; and because the bag clamping device 2 is set on the periphery of the feeding tube 1, a large amount of flying dust will not be generated during feeding.

[0016] The bag clamping device 2 includes a material guide frame tube 21 and a bag clamping block 22. The top of the material guide frame tube 21 is provided with a through hole that is compatible with the feeding tube tube 1, and the feeding tube tube 1 extends from the through hole. Int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com