A hydraulically activated reverse buckle and throw away mechanism

A technology of hands-off mechanism and hydraulic start, which is applied in wellbore/well components, earthwork drilling and production, etc. It can solve the problems of losing hands in advance and unable to rotate the pipe string in advance, and achieves the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

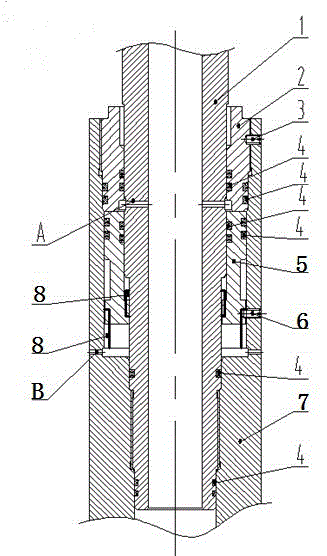

[0023] A hydraulically actuated back-and-forget mechanism, including a feed-in sub, a seal sleeve, a piston, and a drop-in sub, the feed-in sub 1 is connected to the drop-off sub 7 , and the drop-in sub 7 is connected to the feed-in sub 1 An annular space is formed between them, and the sealing sleeve 2 is arranged between the throwing short joint 7 and the feeding short joint 1 to seal the annular space to form an annular cavity. Keyed connection, the feeding nipple 1 is splined with the piston 5, and the piston 5 is positioned by the shear nail 6 and fixed on the hand nipple 7, the feeding nipple 1 has a first through hole A, the first through hole A respectively communicates with the inner hole of the feeding nipple 1 and the annular cavity on the upper part of the piston. There is a second through hole B on the throwing nipple 7, and the second through hole B is respectively connected to the annular cavity and the casing at the lower part of the piston 5. Annulus connectiv...

Embodiment 2

[0029] The present embodiment describes the present invention in detail:

[0030] A hydraulically actuated undercut mechanism, including a feed sub 1, a sealing sleeve 2, a set screw 3, an "O"-shaped sealing ring 4, a piston 5, a shear nail 6, and a drop sub 7, etc. The feeding sub-joint 1 is connected with the drop-off sub-joint 7 by a left-handed thread, and the first through hole A is opened on the feeding sub-joint 1 . A piston 5 is installed in the annulus between the feeding sub-joint 1 and the disengaging sub-joint 7, and the sealing sleeve 2 is connected with the disengaging sub-joint 7 through threads. The outer circle of the piston 5 is connected with the inner hole of the throwing short joint 7 by a spline 8, and the outer circle of the feeding joint 1 is connected with the inner hole of the piston 5 by a spline. The piston 5 is positioned by the shear pin 6 and fixed on the short joint 7. Under the action of the pressure difference between the upper and lower ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com