Method of optimizing steam distribution mode of steam turbine under the effect of backpressure

A technology of steam distribution method and optimization method, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of not considering back pressure, and the efficiency of steam turbine cannot be optimized, and achieve the effect of avoiding frequent actions and improving internal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

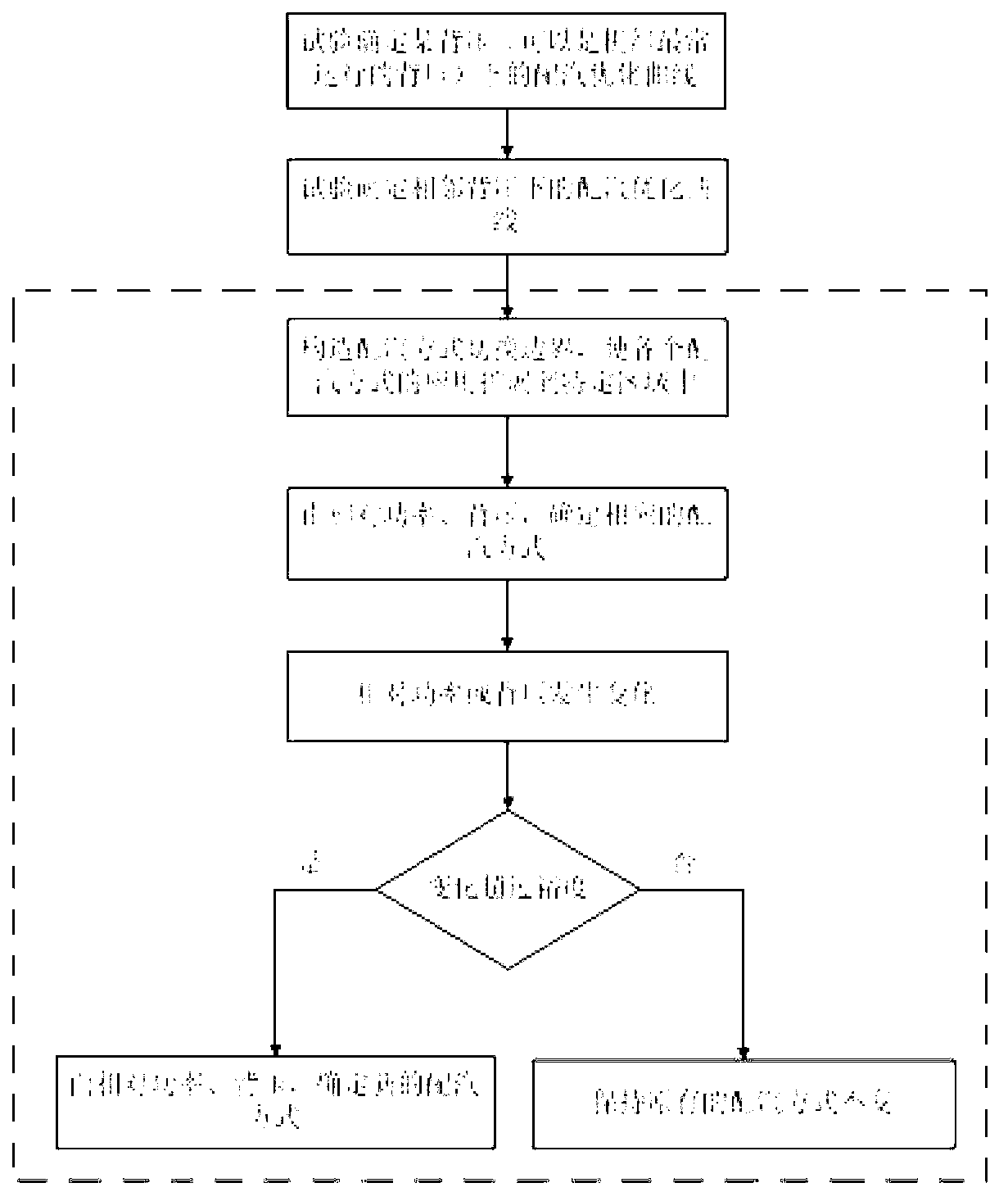

[0028] Specific implementation mode one: the optimization method of the steam distribution mode of the steam turbine under the influence of the back pressure of this embodiment includes the following contents:

[0029] 1. Test to determine the steam distribution optimization curve under a certain back pressure;

[0030] 2. Test to determine the steam distribution optimization curve under adjacent back pressure;

[0031] 3. Construct the switch boundary of steam distribution mode, so that the application of each steam distribution mode can be extended to a specific area;

[0032] 4. The corresponding steam distribution method is determined by the relative power or back pressure: when the point determined by the back pressure or power falls in a certain area, the steam distribution method corresponding to the area is adopted;

[0033] 5. If the relative power or back pressure changes, judge whether the change exceeds the margin and switch the steam distribution mode; if yes, de...

specific Embodiment approach 2

[0043] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the test determines the steam distribution optimization curve under a certain back pressure as follows:

[0044] Known back pressure p i (i=1,...,n-1) under steam turbine steam distribution optimization curve, Represents the power at the switching point of the steam distribution mode, Represents three steam distribution methods;

[0045] According to this turbine steam distribution optimization curve, at the back pressure p i , when the turbine power When using the steam distribution method when turbine power and When using steam distribution method When the turbine power When using the steam distribution method Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0046] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one or two is that: in step two, the steam distribution optimization curve under the adjacent back pressure is tested and determined as follows:

[0047] Known adjacent back pressure p i+1 >p i (i=1,...,n-1) under steam turbine steam distribution optimization curve, similarly, Represents the power at the switching point of the steam distribution mode, Represents three steam distribution methods;

[0048] According to this steam distribution optimization curve, at the back pressure p i+1 , when the turbine power When using the steam distribution method When the turbine power and When using the steam distribution method When the turbine power When using the steam distribution method Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com