System for recovering exhaust steam waste heat of steam turbine to heat condensed water and use method

A technology for steam turbines and condensed water, which is applied in steam applications, steam engine devices, mechanical equipment, etc. It can solve problems such as increased loss of cold sources, unusable waste heat, and complicated operation and maintenance, and achieves reduction of NOX and SO2 emissions, good environmental protection and Energy-saving features, high equipment integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

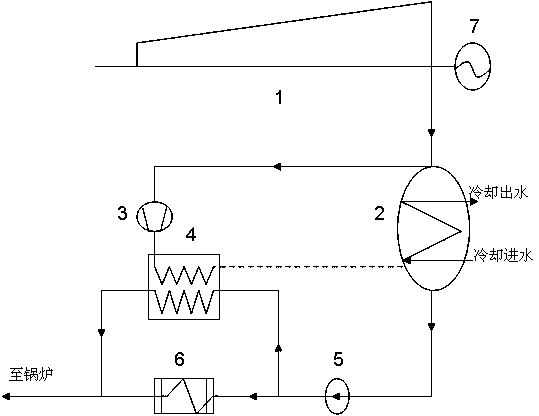

[0024] Such as figure 1 As shown, a system and method for recovering steam turbine exhaust waste heat to heat condensed water, including a steam turbine 1, a condenser 2, a compressor fan 3, a exhaust steam heat exchanger 4, a condensed water pump 5, a No. 1 low-pressure heater 6, Generator 7, energy harvester 8, flow regulating valve 9. The energy harvester 8, the compressor fan 3, the gas side of the exhaust steam heat exchanger 4, and the condenser 2 are connected sequentially through pipelines, the exhaust steam is extracted by the compressor fan 3, enters the exhaust steam heat exchanger 4, and the condensed water returns to the condenser 2. The outlet of the condenser 2 is provided with a condensate pump 5 , the No. 1 low pressure heater 6 is connected in parallel with the exhaust steam heat exchanger 4 , and the outlet of the condensate pump 5 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com