Method utilizing optical fiber composite overhead ground wire redundant cable to solve cross sensitivity existing in optical fiber Brillouin scattering monitoring

A technology of Brillouin scattering and overhead ground wire, which is applied in the direction of using optical devices, measuring devices, measuring heat, etc., and can solve problems such as temperature and strain cross-sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

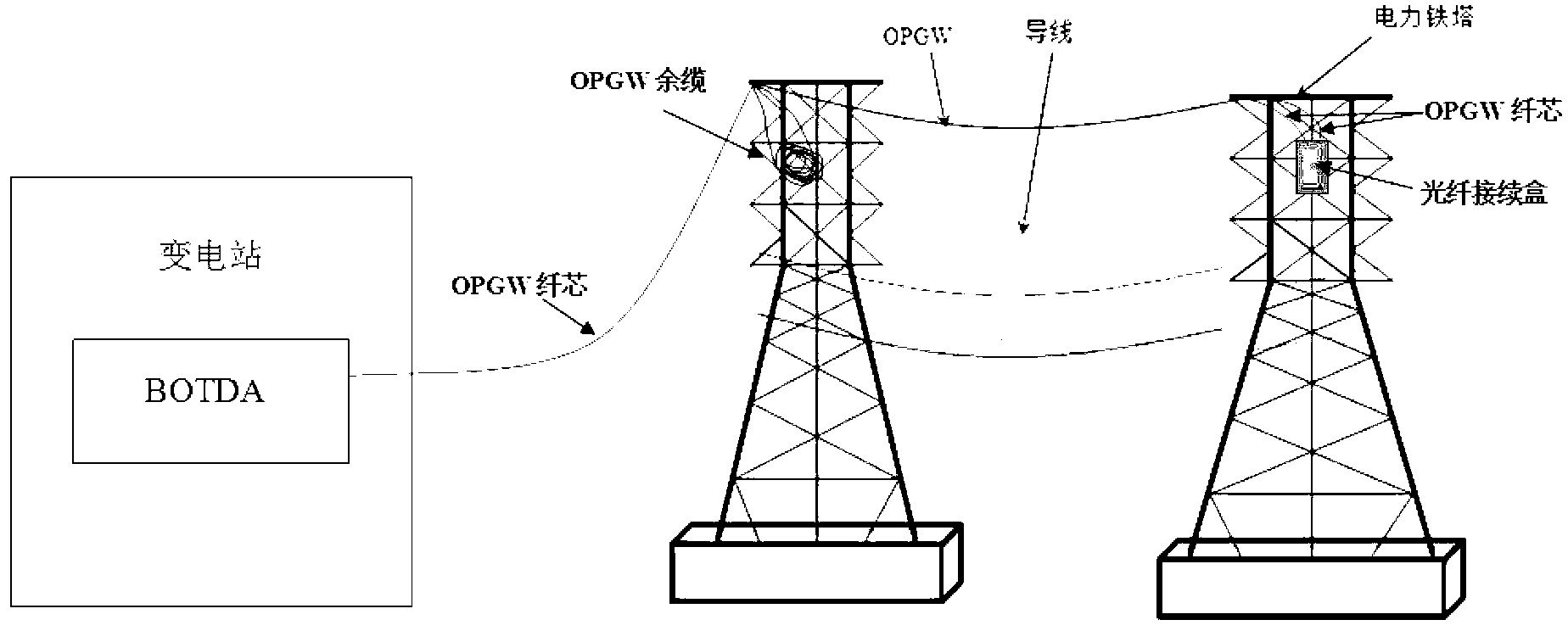

[0036] In the present invention, an OPGW connection box is provided on a part of the corner tower or the tension tower of the power transmission line, and a section of OPGW optical cable is arranged at the connection box. During monitoring, only temperature changes will cause Brillouin scattering frequency shift, and stress factors such as icing and wind will not cause Brillouin scattering frequency shift. This section of OPGW optical cable is named as OPGW remaining cable.

[0037] When the present invention uses Brillouin scattering sensing technology to monitor the state of the OPGW, the remaining OPGW cables on the power tower are only affected by temperature, and are used for temperature compensation of the monitoring results of the overhead OPGW, and the temperature and strain of the overhead OPGW are demodulated. parameters.

[0038] The invention uses the Brillouin scattering sensing technology to monitor the two parameters of temperature and strain along the OPGW to r...

Embodiment 2

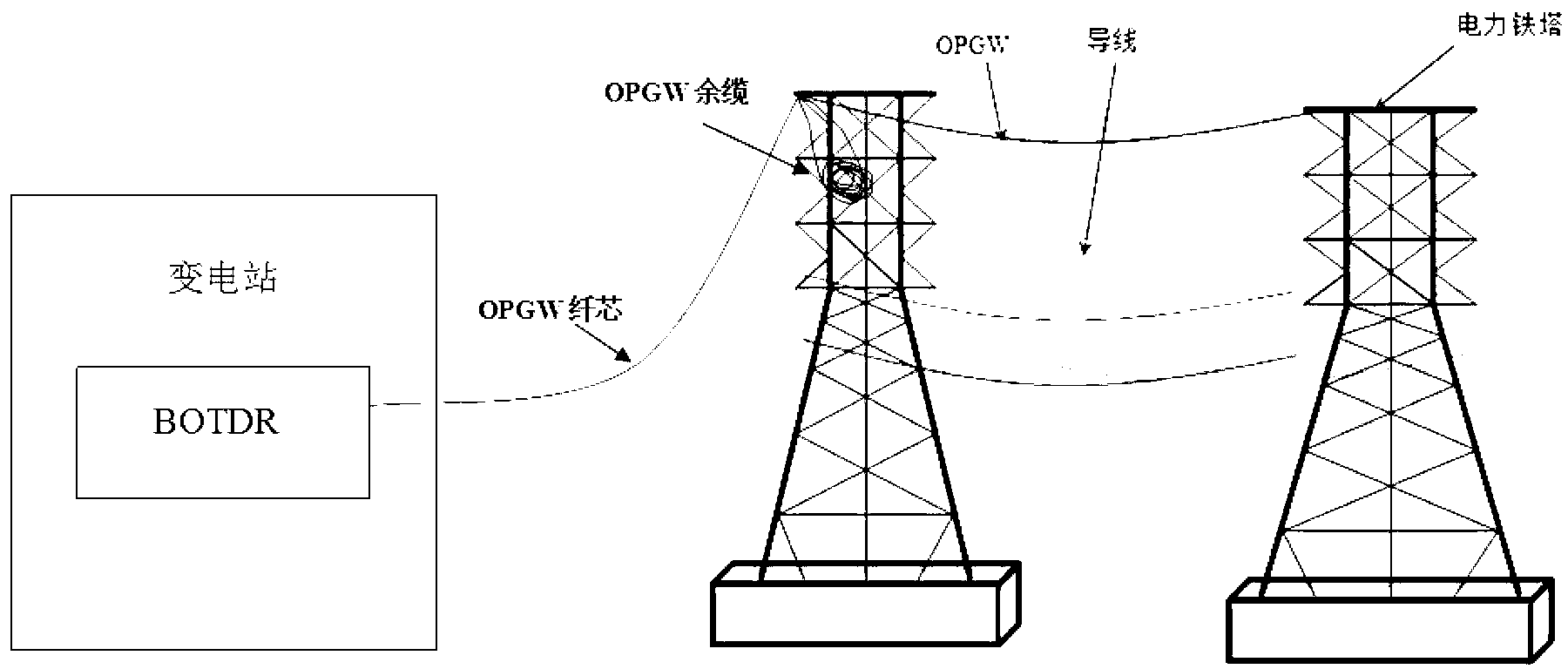

[0041] Such as figure 2 As shown, the BOTDR is placed in the substation and connected to an OPGW fiber core. According to the formulas (3) and (4), the temperature and strain of the OPGW can be monitored, which can reflect the operating status of the OPGW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com