LED display screen with same-color chips arrayed diagonally and method for reusing pixels

An LED display, pixel multiplexing technology, applied in static indicators, instruments, identification devices, etc., can solve the problems of difficult circuit board wiring, blurred images, etc., to avoid blurred images, reduce wiring pressure, and route wiring. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

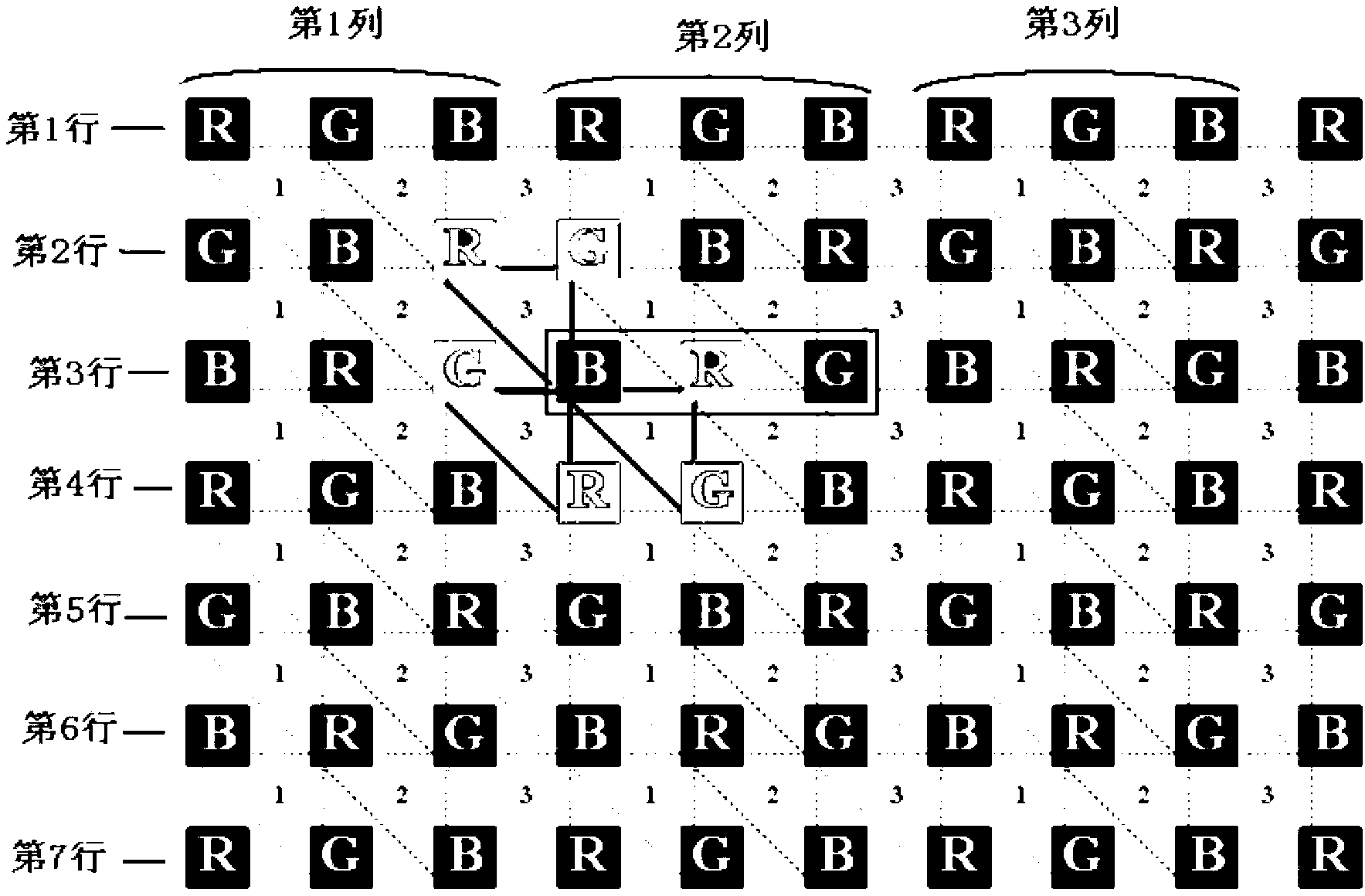

[0036] Such as figure 1 As shown, R, G, and B respectively represent the red, green, and blue primary color LED chips on the display screen. The three-primary-color LED chips on the circuit board are aligned vertically and horizontally, and are evenly spaced in the order of R, G, and B in the horizontal direction from left to right and vertically from top to bottom. The connecting line is a slanted line at 45 degrees. In the oblique direction of 135 degrees, in the order of R, G, and B, they are arranged obliquely in turn; a group of red, green, and blue primary-color LED chips horizontally or vertically form a physical pixel point. Except for the edge LED chips, each LED chip and its surroundings The six LED chips form three triangles containing red, green and blue primary color LED chips. The three triangles including red, green and blue primary color LED chips share the LED chip. For example, each blue LED chip B and its surrounding three green LED chips G and three red ...

Embodiment 2

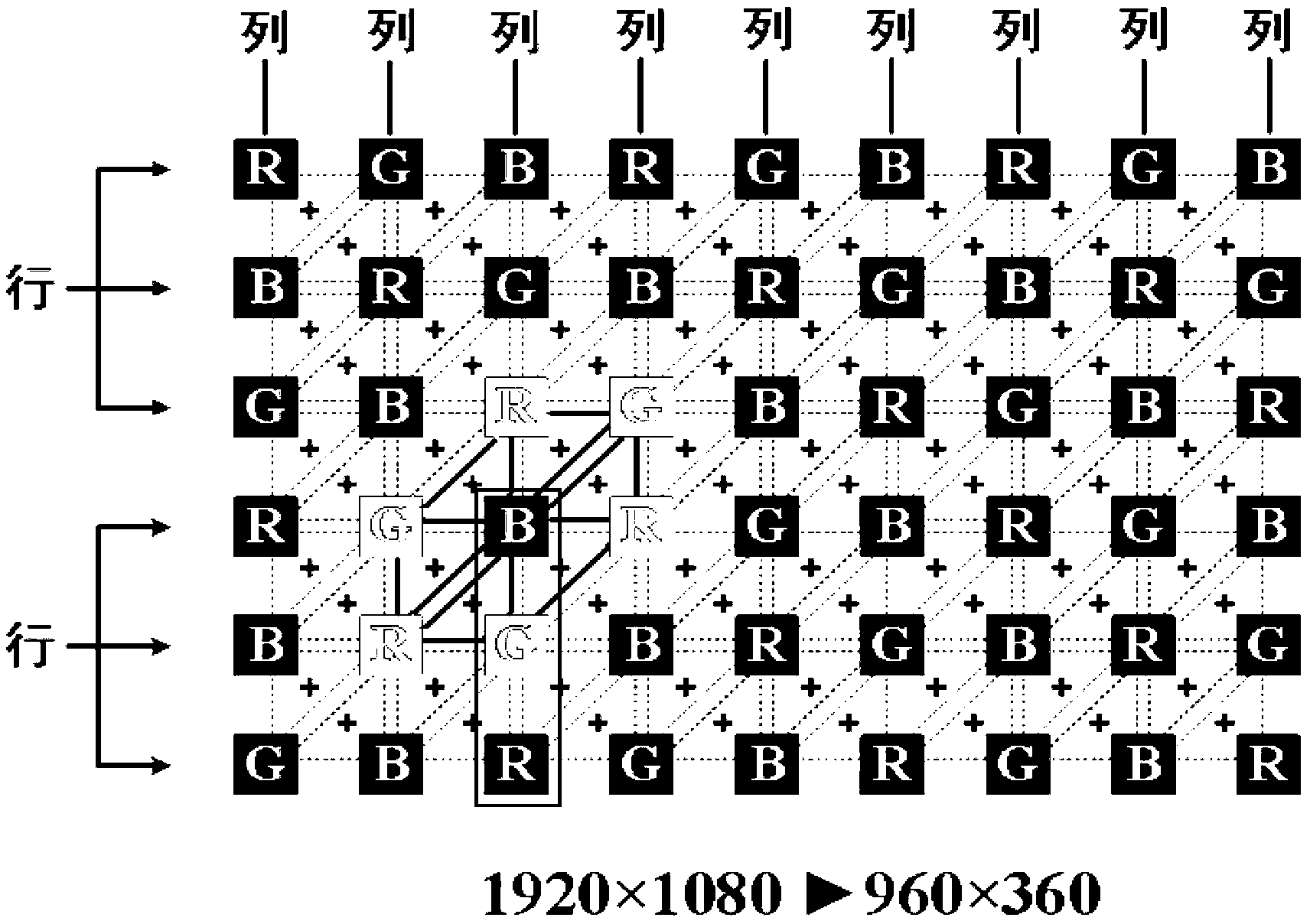

[0055] Such as figure 2 As shown, R, G, and B respectively represent the red, green, and blue primary color LED chips on the display screen. The three-primary-color LED chips on the circuit board are aligned vertically and horizontally. The horizontal spacing between the LED chips is not equal to the vertical spacing, and they are evenly spaced in the order of R, G, and B from left to right in the horizontal direction, and from top to bottom in the vertical direction. Arrange evenly at equal intervals in the order of R, B, and G. The connection lines of the LED chips of each primary color on the display screen are oblique lines. In the direction perpendicular to the oblique line, they are arranged diagonally in the order of R, B, and G; a group of red, green, and blue primary-color LED chips in the vertical direction form a physical pixel point. Except for the edge LED chips, each LED chip and its surroundings The six LED chips form six triangles including red, green and bl...

Embodiment 3

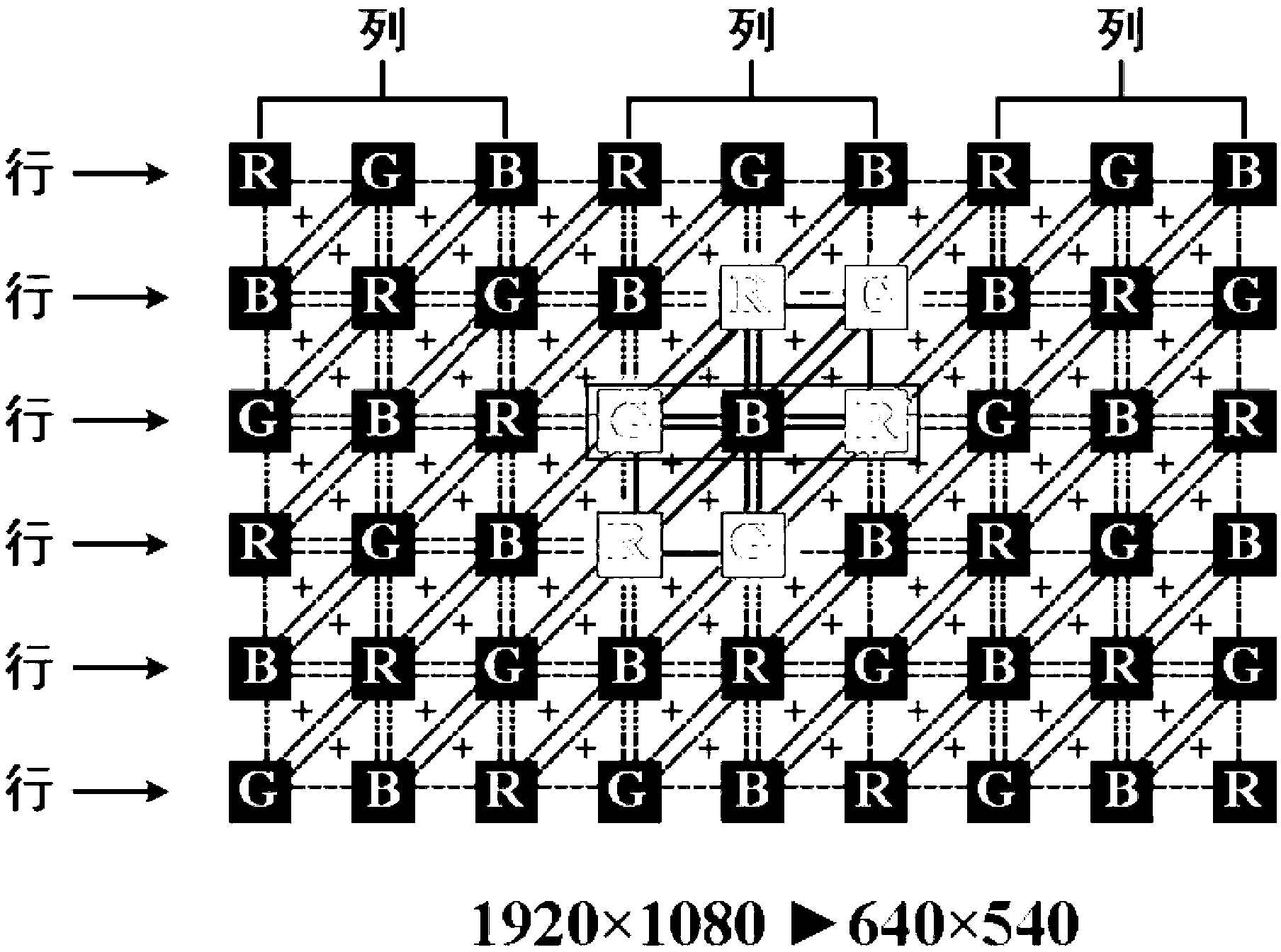

[0074] Such as image 3 As shown, R, G, and B respectively represent the red, green, and blue primary color LED chips on the display screen. The three-primary-color LED chips on the circuit board are aligned vertically and horizontally. The horizontal spacing between the LED chips is smaller than the vertical spacing, and they are evenly spaced in the order of R, G, and B from left to right in the horizontal direction. The order of R, B, and G is evenly spaced. The connection lines of the LED chips of each primary color on the display screen are oblique lines. In the direction perpendicular to the oblique line, they are arranged obliquely in the order of R, B, and G; a group of red, green, and blue primary color LED chips in the horizontal direction form a physical pixel point. Except for the edge LED chips, each LED chip and its surroundings The six LED chips form six triangles including red, green and blue primary color LED chips. Six triangles including red, green and bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com