Passive-driven micro-channel heat-sink cooling device

A heat dissipation cooling and micro-channel technology, which is applied in the cooling/heating device, lighting device, cooling/ventilation/heating renovation of lighting devices, etc., can solve the problem of large dependence on external coolant and power supply, reduce safety and reliability, and restrict popularization and application. and other problems, to achieve the effect of enhancing movement instability and strong cooling and temperature control effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific embodiments and drawings, but the embodiments of the present invention are not limited thereto.

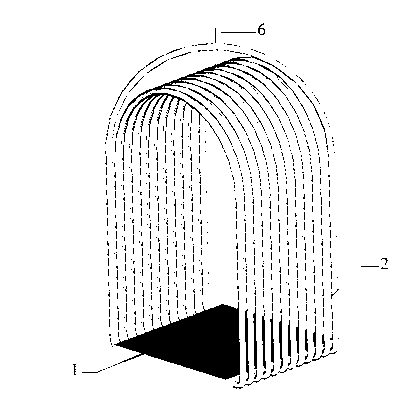

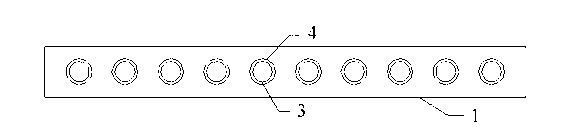

[0020] Such as Figure 1 to Figure 4 As shown, a passively driven microchannel heat dissipation and cooling device according to an embodiment of the present invention is mainly composed of a copper plate heat sink 1 containing a microchannel array and a copper capillary 2 connected to the microchannel 3. The cross section of the microchannel 3 is circular, with a diameter between 0.2 and 1.5mm. The inner diameter of the copper capillary 2 is equal to the diameter of the microchannel 3, and the outer diameter of the copper capillary 2 is with the stepped expansion outside the ports on both sides of the microchannel 3. The diameters are equal, and the sudden expansion 4 and the copper capillary 2 can be plugged and unplugged. The copper capillary tube 2 and the microchannel 3 in the copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com