Three-dimensional pulsating heat pipe heat radiation and cooling device with flat plate microchannel evaporator

A pulsating heat pipe, heat dissipation and cooling technology, which is applied in the cooling/heating device, lighting device, cooling/ventilation/heating renovation of lighting devices, etc. Safety and reliability reduction and other issues, to achieve the effect of no maintenance production cost, strong cooling and temperature control effect, and enhanced reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with specific embodiments and drawings, but the embodiments of the present invention are not limited thereto.

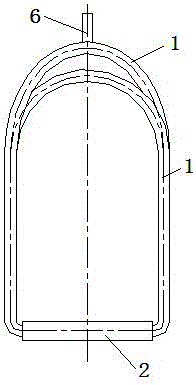

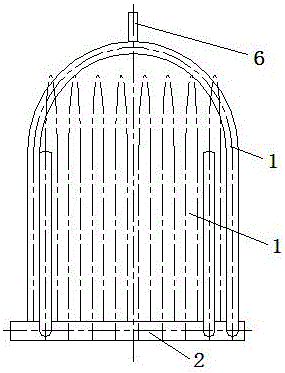

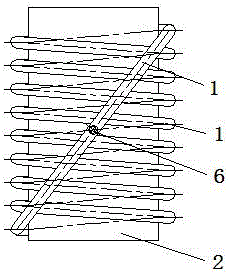

[0025] An embodiment of the three-dimensional pulsating heat pipe cooling device with flat plate microchannel evaporator of the present invention is as follows Figure 1 to Figure 3 As shown, it includes a metal plate evaporator 2 with a microchannel array inside and a capillary tube. The bottom surface of the metal plate evaporator 2 is used to connect with high-power microelectronic devices or LED lamps. The microchannel 3 in the metal plate evaporator 2 It is arranged between the upper surface and the bottom surface of the metal plate evaporator 2, and the ports of each microchannel 3 are respectively arranged on the left and right sides of the metal plate evaporator 2, and the capillary 1 is connected with the microchannel 3. The capillary 1 in this embodiment adopts Copper capi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com