Clamp improving rotary knob installation coaxiality and assembling method using same

A coaxiality and knob technology, applied in the field of tooling fixtures, can solve the problem that coaxiality cannot be guaranteed, and achieve the effect of improving the coaxiality of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

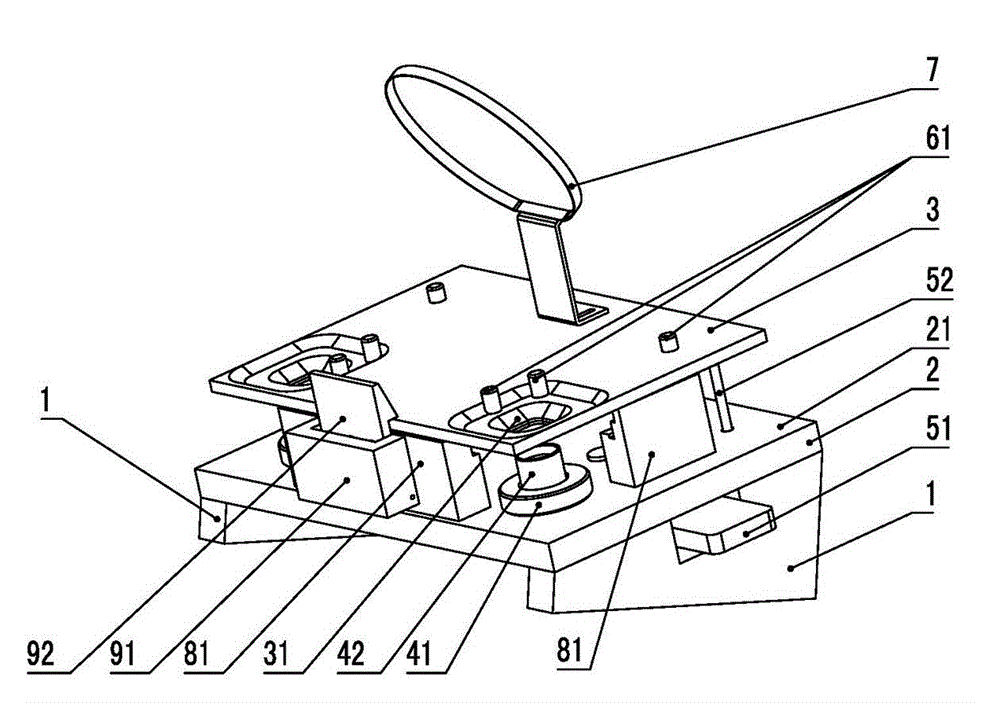

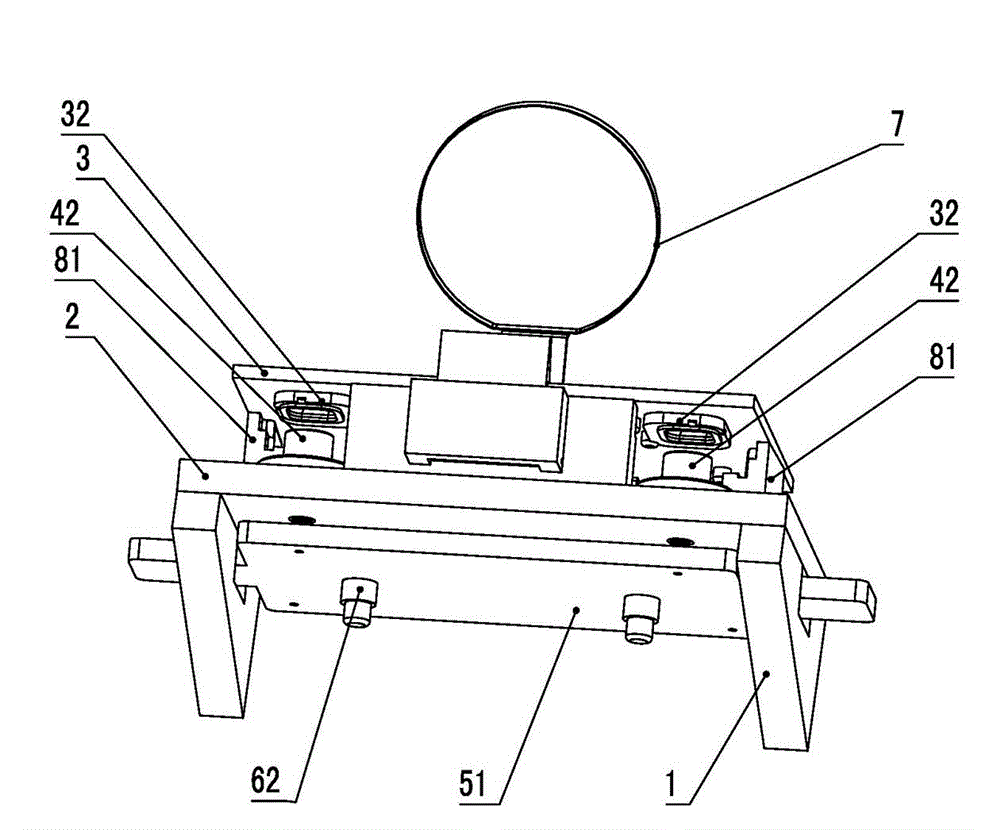

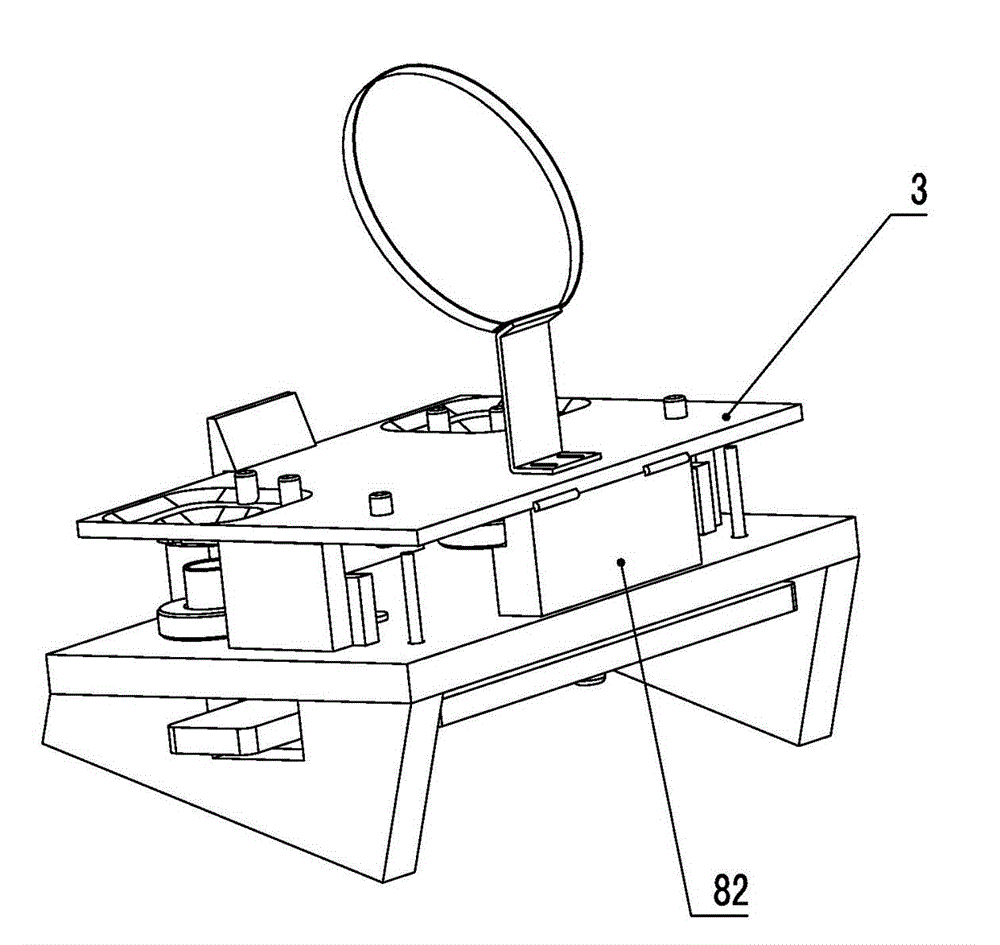

[0033] Figure 1 to Figure 7 The reference numerals in are: support base plate 1; lower plate 2; first installation reference plane 21; upper cover plate 3; avoidance through hole 31; elastic soft rubber 32; movable limit ring 41; 42; slider 421; oil storage tank 4211; cylinder body 422; avoidance groove 423; positioning hole 424; second installation reference plane 425; top plate 51; thimble 52; return spring 53; upper spring plunger 61; lower spring plunger 62; air suction port fixing bracket 7; height positioning block 81; hinge seat 82; elastic buckle seat 91; block 92.

[0034] Such as Figure 1 to Figure 7 As shown, a fixture for improving the coaxiality of knob installation includes a support base plate 1, a lower plate 2, an upper cover plate 3 and a movable positioning mechanism, the lower plate 2 is arranged on the support base plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com