A method for assembling the stator and rotor shafts of a motor

A stator-rotor and shaft assembly technology, which is applied in the direction of centering/balancing the rotor, etc., can solve the problems of difficult measurement accuracy, difficult test operation space, uneven stator-rotor air gap, etc., to improve the installation coaxiality and improve the performance of the motor , Improve the effect of operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

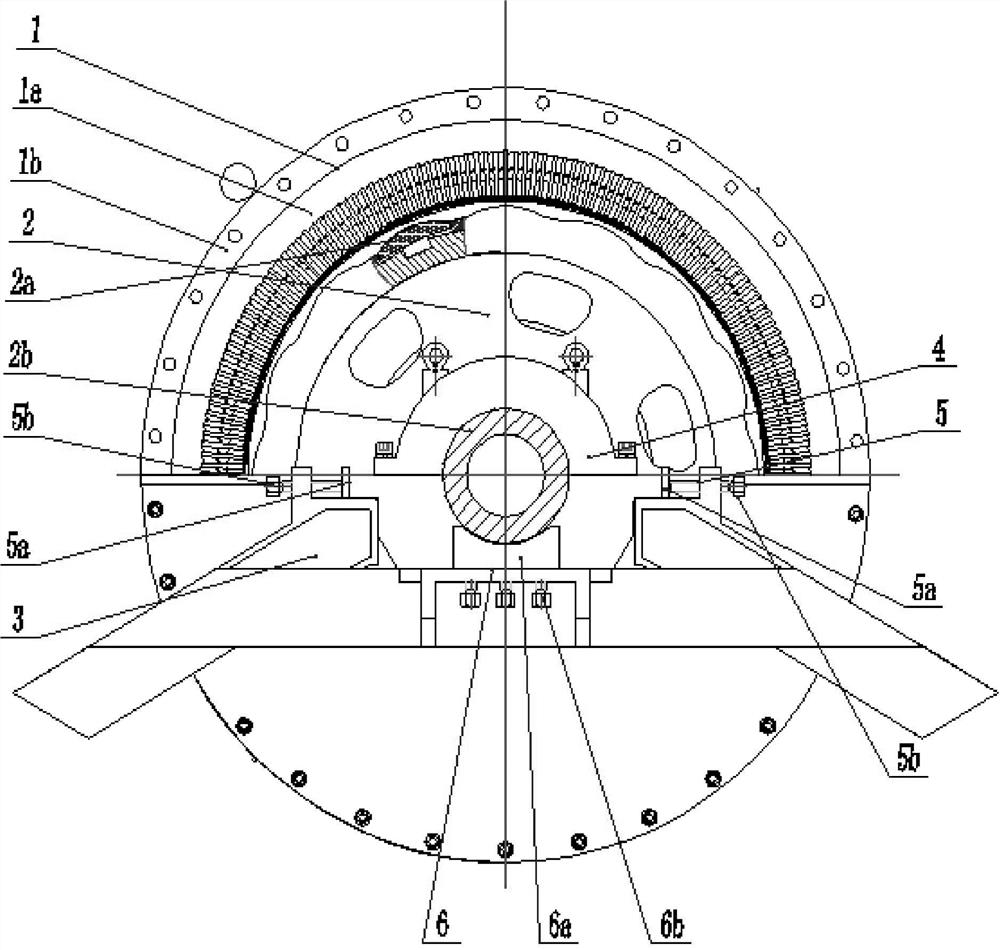

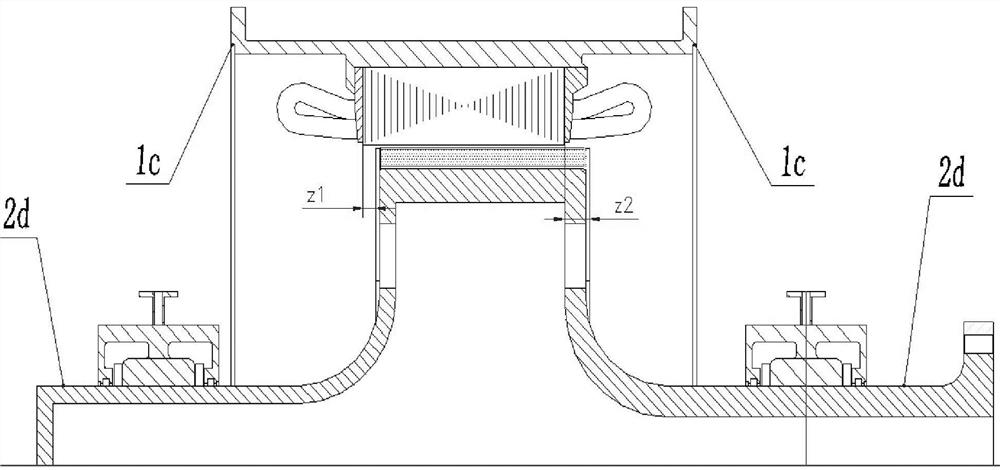

[0023] refer to figure 1 and figure 2 As shown, the invention discloses a method for assembling the stator and rotor shafts of a motor. When the stator core 1a is assembled in the stator frame 1b, the inner circle of the stator core 1a is used as a reference, and the characteristic stops are processed at both ends of the stator frame 1b in advance. The coaxiality of the mouth 1c, the characteristic seam 1c and the inner circle of the stator core 1a is determined according to the design requirements.

[0024] The assembly object of this patent is composed of a stator assembly 1, a rotor assembly 2, an end cover 3 and a bearing assembly 4. The stator assembly 1 is composed of a stator core 1a and a stator frame 1b, and the rotor assembly 2 is composed of a rotor core 2a , the rotating shaft 2b, the rotor end plate 2c and the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com