High precision encoder installing and connecting apparatus

A technology of high-precision encoders and connecting devices, which is applied in the direction of measuring devices, instruments, and conversion sensor outputs, to achieve the effect of high installation coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

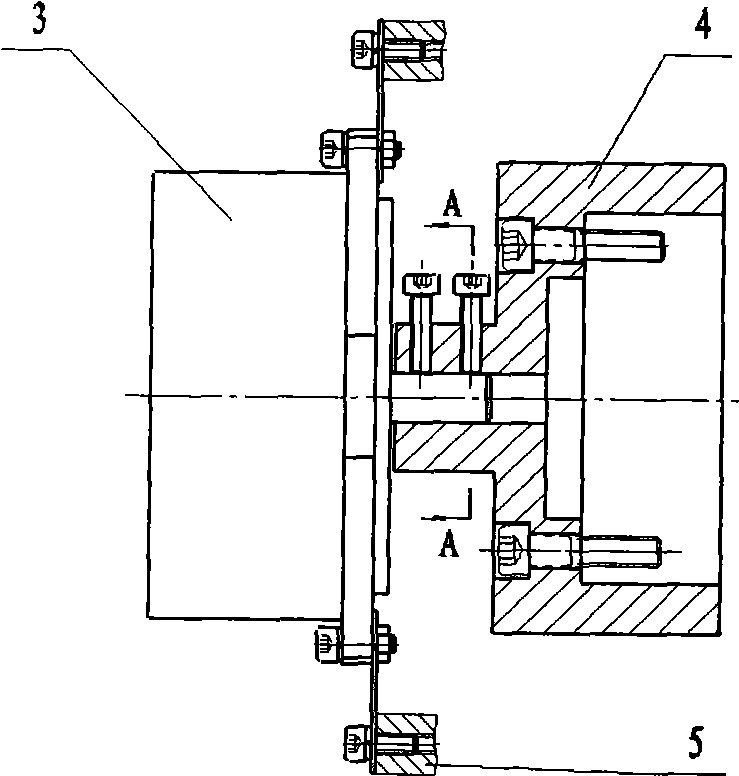

[0019] Such as figure 1 , figure 2 As shown, a high-precision encoder installation and connection device includes a rigid connector 4 and an elastic piece 2. One end of the rigid connector 4 is positioned and installed with the measuring shaft through a cylindrical hole and the end face, and the other end is socketed with the encoder shaft through a cylindrical hole. , There is an adjustment gap between the rigid connector 4 and the encoder shaft, and the cylindrical holes at both ends are coaxial. One end of the rigid connector 4 connected to the encoder is provided with at least 2 rows of fine-tuning screws 1 mounted radially, 3 of each row are evenly distributed along the circumference, one end of the elastic piece 2 is connected to the encoder housing 3, and the other One end is connected with the fixed seat 5.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com