Damping and noise reducing device for steering pull rod inner ball joint assembly

A technology of steering rods and ball joints, applied in steering rods, steering mechanisms, transportation and packaging, etc., can solve the problems of not being able to add redundant parts and limited space in the housing parts, so as to improve the hand feel, maintain a happy mood, and reduce wear and tear on parts and noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

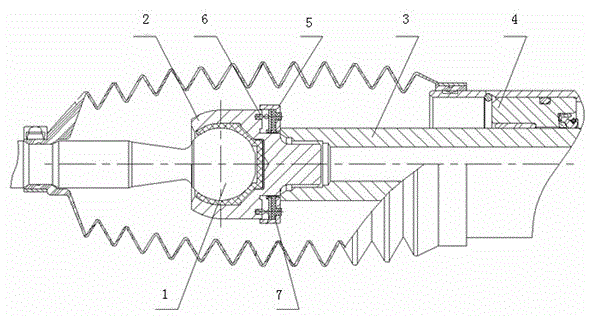

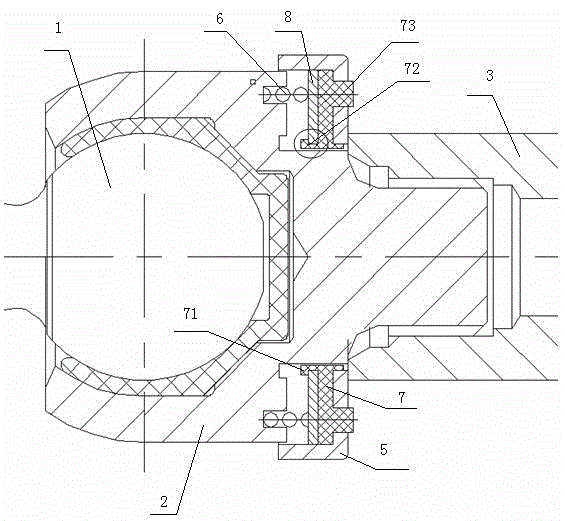

[0017] like figure 1 , the shock and noise reduction device of the inner ball joint assembly of the steering tie rod of the present invention comprises an inner ball head 1, an inner ball head seat 2, a rack 3, and a limit sleeve 4, and the inner ball head seat 2 and the end of the rack 3 are fixed connection, the limit sleeve 4 is set on the rack 3, and a sleeve 5 is also provided between the front end surface of the inner ball seat 2 and the end surface of the rack. The sleeve 5 is set on the front end of the inner ball seat 2, and the inner ball An elastic support structure of a spring 6 and a washer 7 is provided between the front end surface of the head seat 2 and the inner end surface of the sleeve 5 .

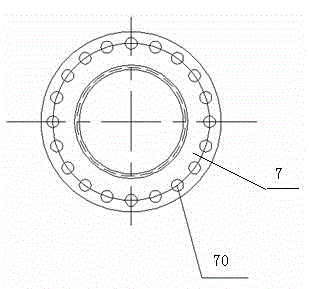

[0018] Specifically, a spacer 8 is also provided between the washer 7 and the spring 6, and the spacer 8 is fixed on the spacer 7. A plurality of protrusions are arranged on the contact surface between the spacer 7 and the spacer 8, and the protrusions are arranged in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com