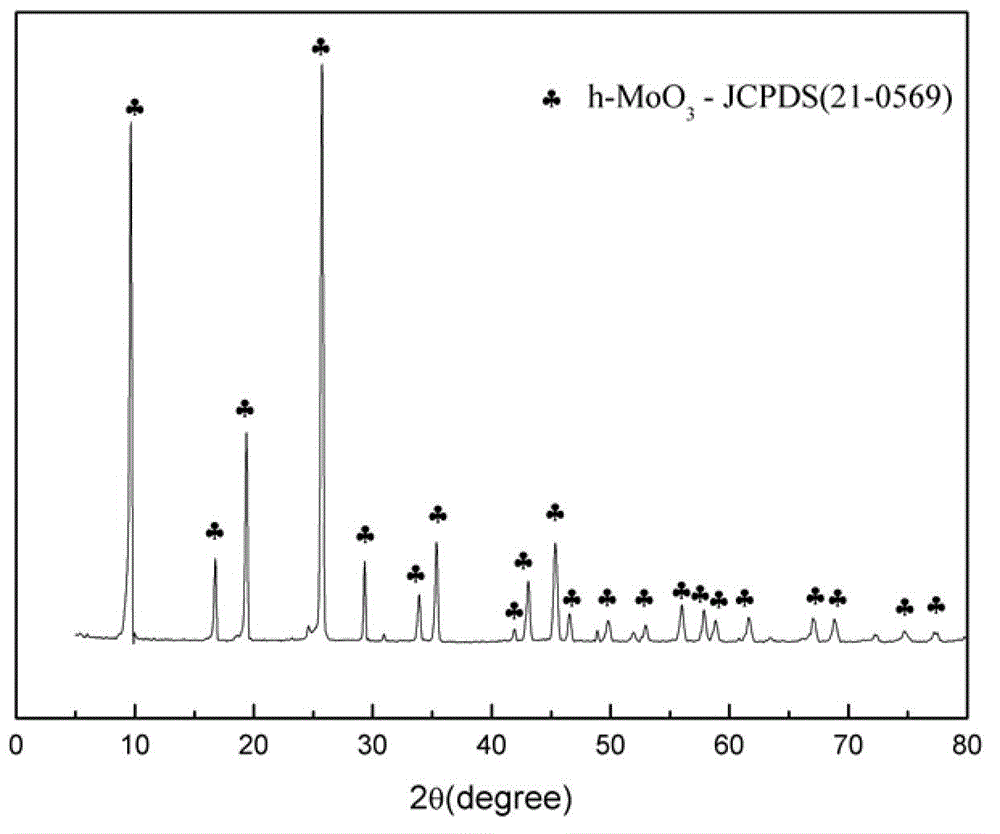

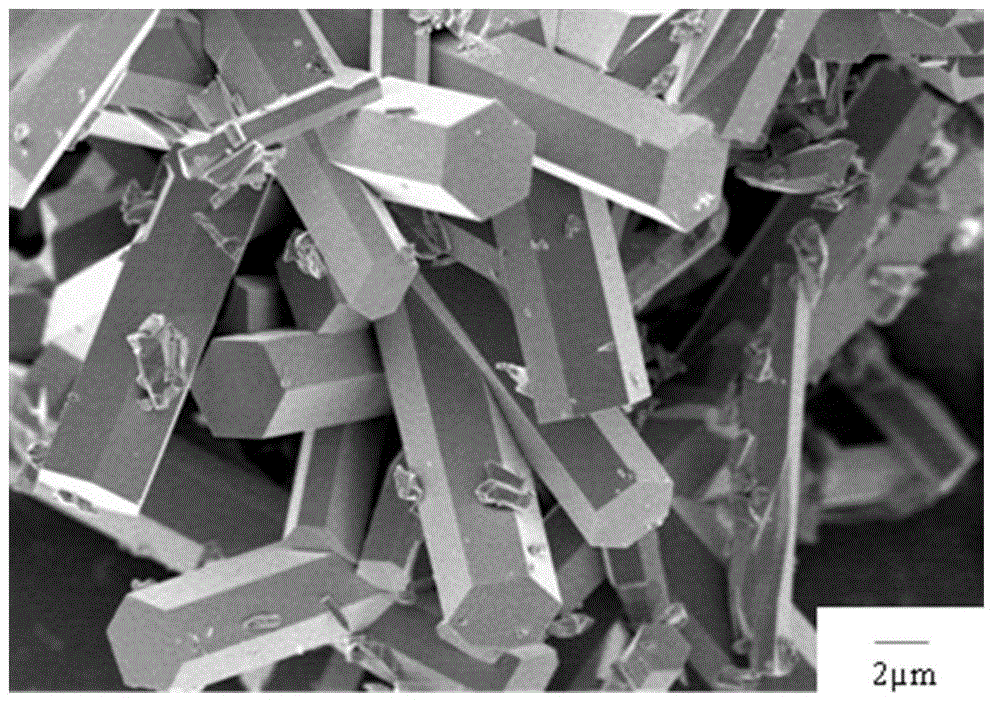

Method for preparing h-MoO3 nano rod in microwave-ultraviolet mode

An h-moo3, nanorod technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of side reactions, difficult reactions, high reaction temperature, and achieve the reaction cycle. Short, low cost, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Analytical pure ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) join in deionized water and stir to make the concentration of ammonium molybdate is the solution A of 0.005mol / L;

[0018] 2) After stirring and dissolving solution A evenly, use 3mol / L HNO 3 The solution adjusts the pH value of solution A to 1.0 to obtain solution B;

[0019] 3) Pour solution B into a four-necked round-bottomed flask, put the equipped four-necked round-bottomed flask into a UWave-1000 microwave, ultraviolet, and ultrasonic trinity synthesis extraction reaction apparatus, and fix it, using direct temperature measurement method Temperature measurement (platinum resistance temperature measurement);

[0020] 4) Adopt the microwave-ultraviolet synthesis mode, the power of the ultraviolet lamp is 300W, the central wavelength of the ultraviolet lamp is 365nm, select the temperature-time working mode, set the reaction temperature to 60°C, the time to 100min, the microwave heating time to ...

Embodiment 2

[0023] 1) Analytical pure ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) join in deionized water and stir to make the concentration of ammonium molybdate is the solution A of 0.01mol / L;

[0024] 2) After stirring and dissolving solution A evenly, use 4mol / L HNO 3 The solution adjusts the pH of solution A to be 1.5 to obtain solution B;

[0025] 3) Pour solution B into a four-necked round-bottomed flask, put the equipped four-necked round-bottomed flask into a UWave-1000 microwave, ultraviolet, and ultrasonic trinity synthesis extraction reaction apparatus, and fix it, using direct temperature measurement method Temperature measurement (platinum resistance temperature measurement);

[0026] 4) Adopt the microwave-ultraviolet synthesis mode, the power of the ultraviolet lamp is 300W, the central wavelength of the ultraviolet lamp is 365nm, select the temperature-time working mode, set the reaction temperature to 70°C, the time to 90min, the microwave heating time to 10min...

Embodiment 3

[0029]1) Analytical pure ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) join in deionized water and stir to make the concentration of ammonium molybdate is the solution A of 0.008mol / L;

[0030] 2) After stirring and dissolving solution A evenly, use 5mol / L HNO 3 The solution adjusts the pH value of solution A to be 0.8 to obtain solution B;

[0031] 3) Pour solution B into a four-necked round-bottomed flask, put the equipped four-necked round-bottomed flask into a UWave-1000 microwave, ultraviolet, and ultrasonic trinity synthesis extraction reaction apparatus, and fix it, using direct temperature measurement method Temperature measurement (platinum resistance temperature measurement);

[0032] 4) Adopt the microwave-ultraviolet synthesis mode, the power of the ultraviolet lamp is 300W, the central wavelength of the ultraviolet lamp is 365nm, select the temperature-time working mode, set the reaction temperature to 50°C, the time to 120min, the microwave heating time t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com