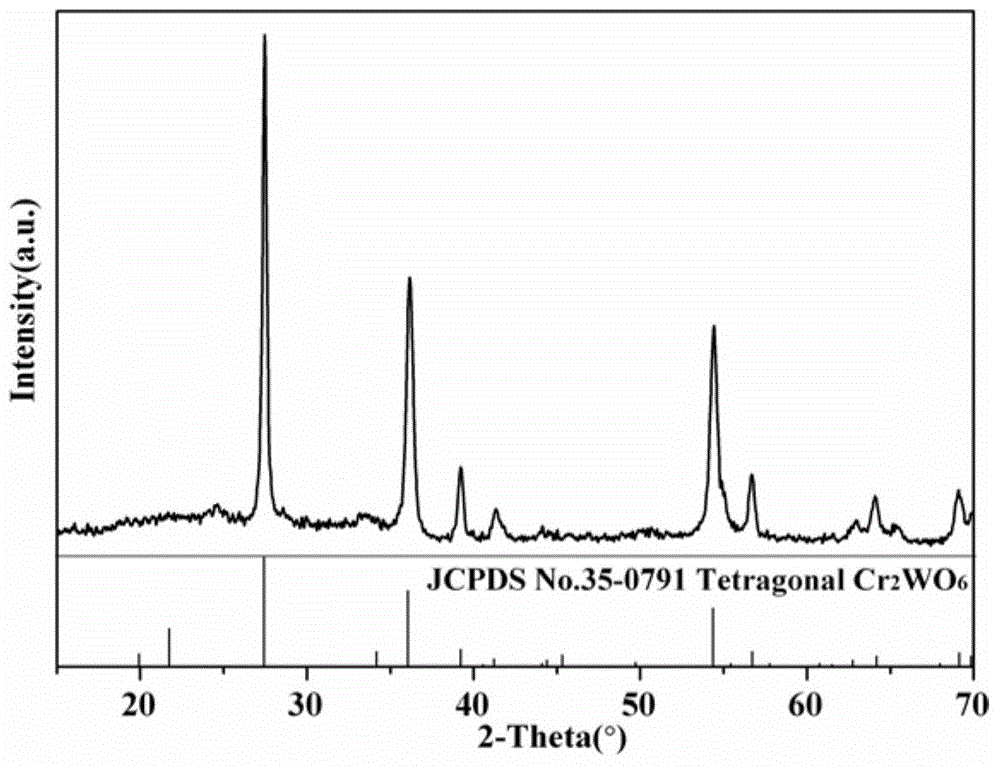

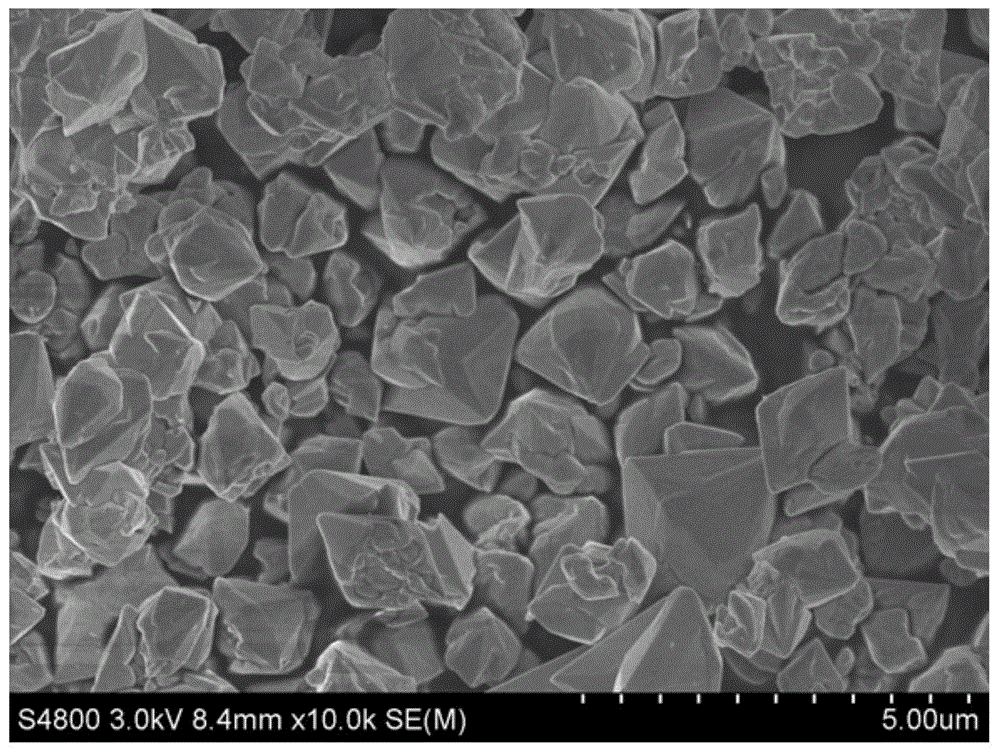

Method for preparing pyramid-shaped Cr2WO6 microcrystalline by hydrothermal-assisted low-temperature calcination

A low-temperature calcination and hydrothermal assisted technology, which is applied in the field of tungstate nanomaterials, can solve the problems of reduced specific surface area of catalysts, unsatisfactory photocatalytic efficiency, and large particle size, so as to achieve controllable product particle size, uniform size, and reaction The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: 6mmol analytically pure Cr(NO 3 ) 3 9H 2 O was added to 15mL of deionized water and stirred continuously to prepare a transparent solution A;

[0027] Step 2: 3mmol analytically pure Na 2 WO 4 2H2 Add O into 15mL deionized water, and keep stirring to prepare a transparent solution B;

[0028] Step 3: According to the volume ratio of transparent solution A: transparent solution B is 2:1, slowly add transparent solution A to transparent solution B, and stir with a magnetic stirrer for 30 minutes to form a green precursor suspension;

[0029] Step 4: adjust the pH of the green precursor suspension to 8.0 with 0.8mol / L sodium hydroxide aqueous solution to obtain a mixture;

[0030] Step 5: Pour the mixture into the hydrothermal reaction kettle, and control the filling degree at 40%; then seal the hydrothermal reaction kettle, put it into a homogeneous reactor, control the hydrothermal temperature at 160°C for 12 hours, and naturally cool to room temperature; ...

Embodiment 2

[0035] Step one: 8mmol analytically pure Cr(NO 3 ) 3 9H 2 O was added to 15mL of deionized water and stirred continuously to prepare a transparent solution A;

[0036] Step 2: 4mmol analytically pure Na 2 WO 4 2H 2 Add O into 15mL deionized water, and keep stirring to prepare a transparent solution B;

[0037] Step 3: According to the volume ratio of transparent solution A: transparent solution B is 1:1, slowly add transparent solution A to transparent solution B, and stir with a magnetic stirrer for 30 minutes to form a green precursor suspension;

[0038] Step 4: adjust the pH of the green precursor suspension to 7.0 with 1mol / L sodium hydroxide aqueous solution to obtain a mixture;

[0039] Step 5: Pour the mixture into the hydrothermal reaction kettle, and control the filling degree at 40%; then seal the hydrothermal reaction kettle, put it into a homogeneous reactor, control the hydrothermal temperature at 180°C for 12 hours, and naturally cool to room temperature;...

Embodiment 3

[0043] Step 1: 6mmol analytically pure Cr(NO 3 ) 3 9H 2 O was added to 20mL deionized water and stirred continuously to prepare a transparent solution A;

[0044] Step 2: 6mmol analytically pure Na 2 WO 4 2H 2 O was added to 20mL deionized water, and stirred continuously, to prepare a transparent solution B;

[0045] Step 3: Slowly add transparent solution A to transparent solution B according to the volume ratio of transparent solution A:transparent solution B of 1:2, and stir with a magnetic stirrer for 30 minutes to form a green precursor suspension;

[0046] Step 4: adjust the pH of the green precursor suspension to 10.0 with 1mol / L sodium hydroxide aqueous solution to obtain a mixture;

[0047] Step 5: Pour the mixture into the hydrothermal reaction kettle, and the filling degree is controlled at 50%; then seal the hydrothermal reaction kettle, put it into a homogeneous reactor, control the hydrothermal temperature at 170°C for 24 hours, and naturally cool to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com