Degradable reinforced plant fiber material and preparation method thereof

A plant fiber material and enhanced technology, applied in the field of degradable enhanced plant fiber material and its preparation, can solve the problems of long production cycle, non-degradable, insufficient strength, etc., achieve shortened production time, reduce irritating odor, improve relative capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

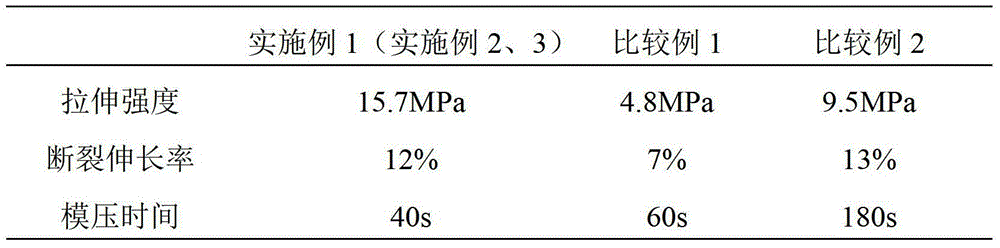

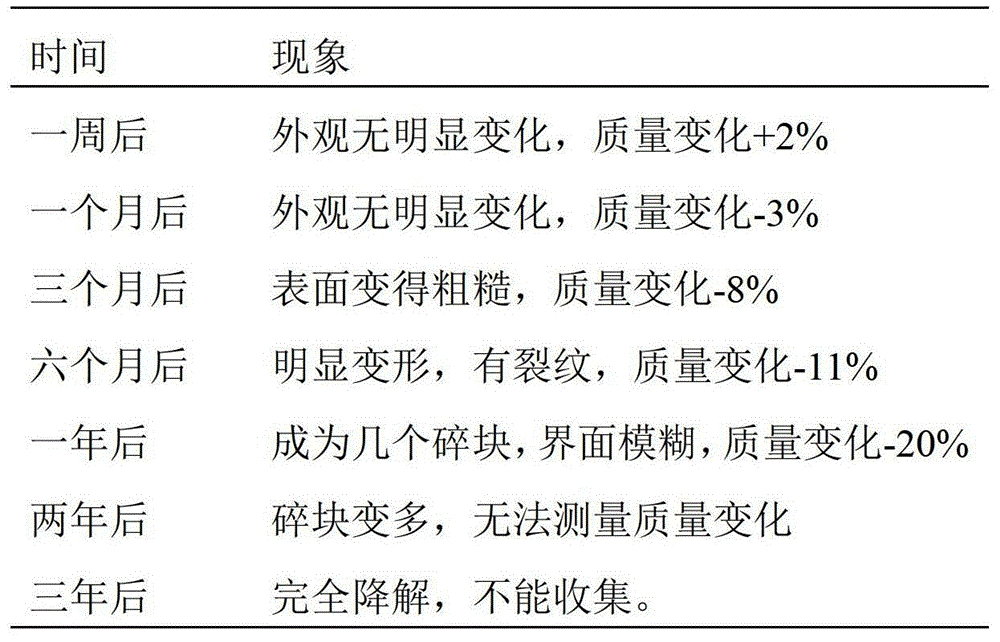

Examples

Embodiment 1

[0033] A degradable reinforced plant fiber material, the plant fiber material is prepared from the following raw materials in weight percentage: rice husk powder 52%, degradable adhesive 14%, reinforcing agent 12.5%, release agent 2%, Water 19.5%, wherein, the degradable adhesive is mixed by weight ratio polyvinyl alcohol: urea-formaldehyde resin=5:2, and the described reinforcing agent is by weight ratio heavy calcium carbonate: nano silicon dioxide= 12:0.5 mixed, the release agent is stearic acid powder;

[0034] The preparation method of the above-mentioned degradable reinforced plant fiber material, the steps are as follows:

[0035] (1) Put 5.2kg of 50-mesh rice husk powder, 1kg of powdered polyvinyl alcohol, 0.4kg of powdered urea-formaldehyde resin, 1.2kg of heavy calcium carbonate, 0.05kg of nano-silica, and 0.2kg of stearic acid in the mixer , Stir for 3 minutes first, then continue to stir and add 1.95kg of water until the mixture is uniform, and prevent agglomerati...

Embodiment 2

[0038] A degradable reinforced plant fiber material, the plant fiber material is prepared from the following raw materials by weight percentage: rice husk powder 51%, degradable adhesive 14%, reinforcing agent 13%, release agent 2%, 20% water, wherein, the degradable adhesive is mixed by weight ratio of polyvinyl alcohol: urea-formaldehyde resin=5:2, and the reinforcing agent is made of weight ratio of heavy calcium carbonate: nano silicon dioxide= 12:1 mixed, the release agent is stearic acid powder;

[0039] The preparation method of the above-mentioned degradable reinforced plant fiber material, the steps are as follows:

[0040] (1) Put 5.1kg of 50-mesh rice husk powder, 1kg of powdered polyvinyl alcohol, 0.4kg of powdered urea-formaldehyde resin, 1.2kg of heavy calcium carbonate, 0.1kg of nano-silica, and 0.2kg of stearic acid in the mixer. , Stir for 3 minutes first, then continue to stir and add 2kg of water until the mixture is uniform, and prevent agglomeration durin...

Embodiment 3

[0043] A degradable reinforced plant fiber material, the plant fiber material is prepared from the following raw materials in weight percentage: rice husk powder 41.6kg, powdery polyvinyl alcohol 8kg, powdery urea-formaldehyde resin 3.2kg, heavy calcium carbonate 9.6kg kg, nano silicon dioxide 0.4kg, zinc stearate 1.6kg, water 15.6kg.

[0044] The preparation method of the above-mentioned degradable reinforced plant fiber material, the steps are as follows:

[0045] (1) Put 41.6kg of 50-mesh rice husk powder, 8kg of powdered polyvinyl alcohol, 3.2kg of powdered urea-formaldehyde resin, 9.6kg of heavy calcium carbonate, 0.4kg of nano-silicon dioxide, and 1.6 kg of zinc stearate into the mixer in turn. kg, first stir for 3 minutes and then continue to stir and add 15.6kg of water until the mixture is uniform. During the stirring process, agglomeration should be prevented.

[0046] (2) Preheat the molding machine to 110°C, add 50-100g of raw materials into each mold, pressurize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com