H-shaped steel puller

A technology of H-section steel and section steel, which is used in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of shortening the service life of materials, increasing the cost, and pulling the hair, so as to increase the stress area, prolong the service life, and reduce the hair pulling. and possible effects of deformation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

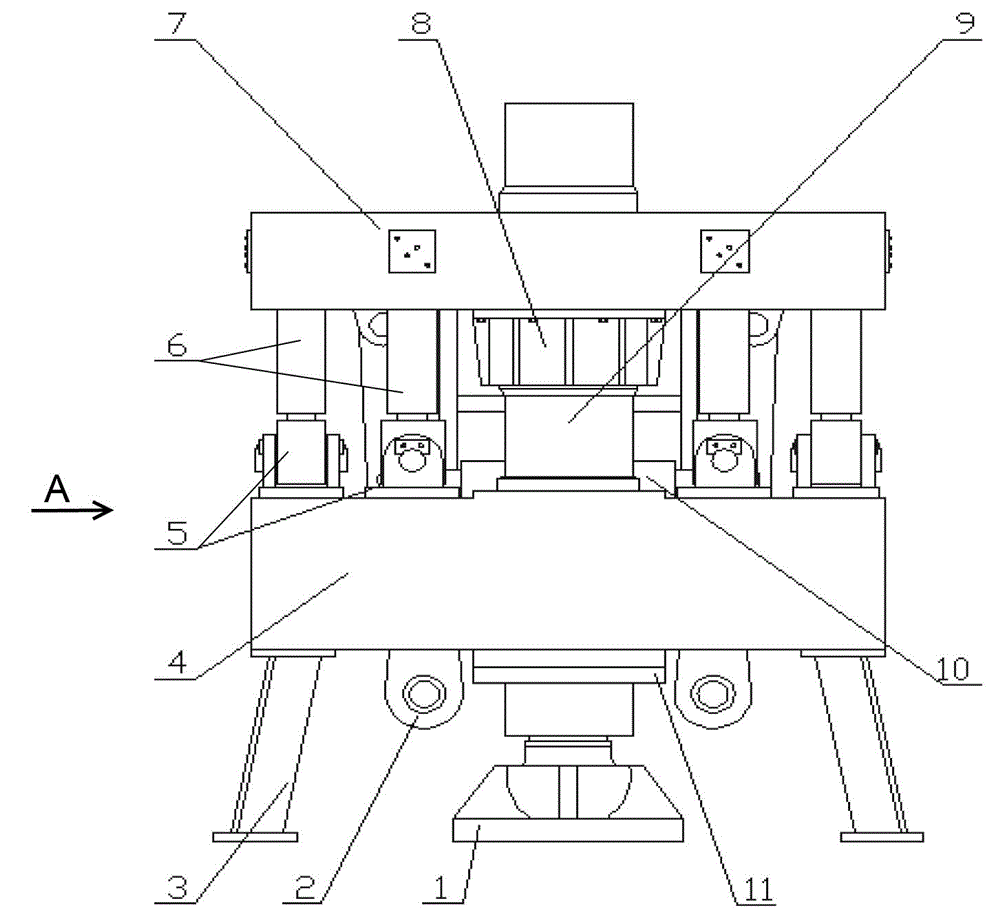

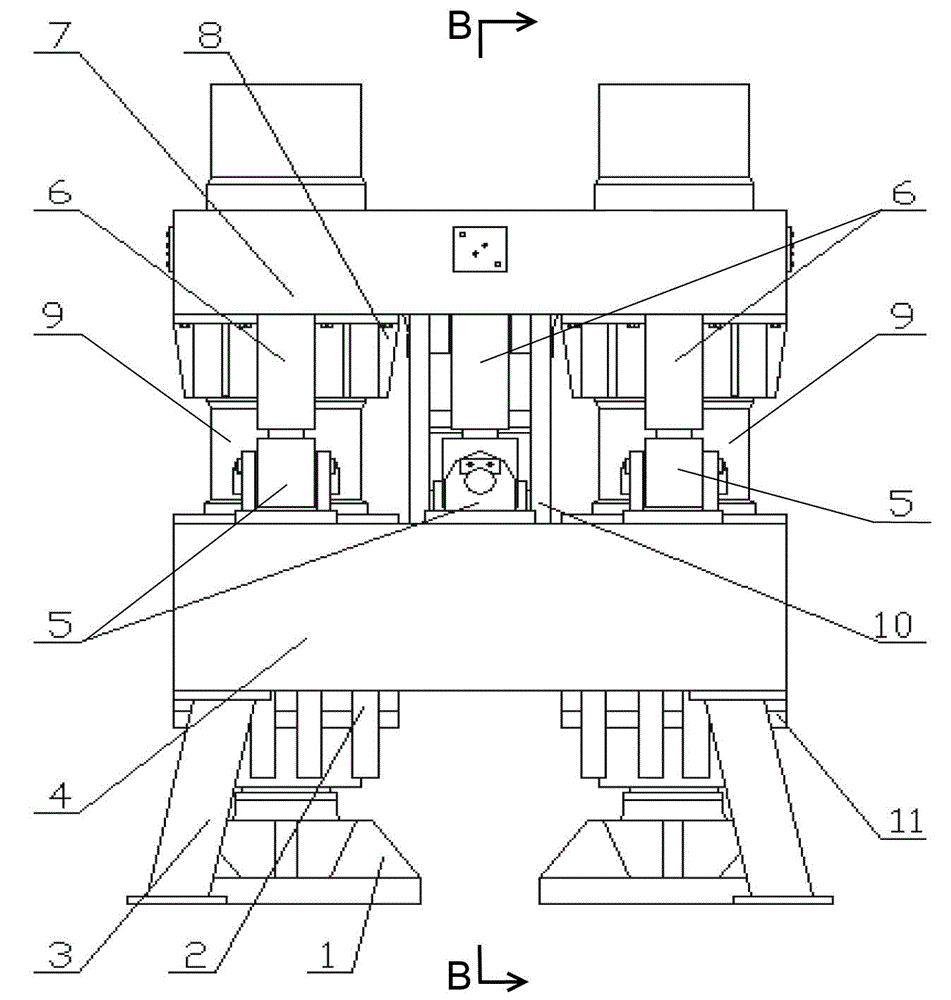

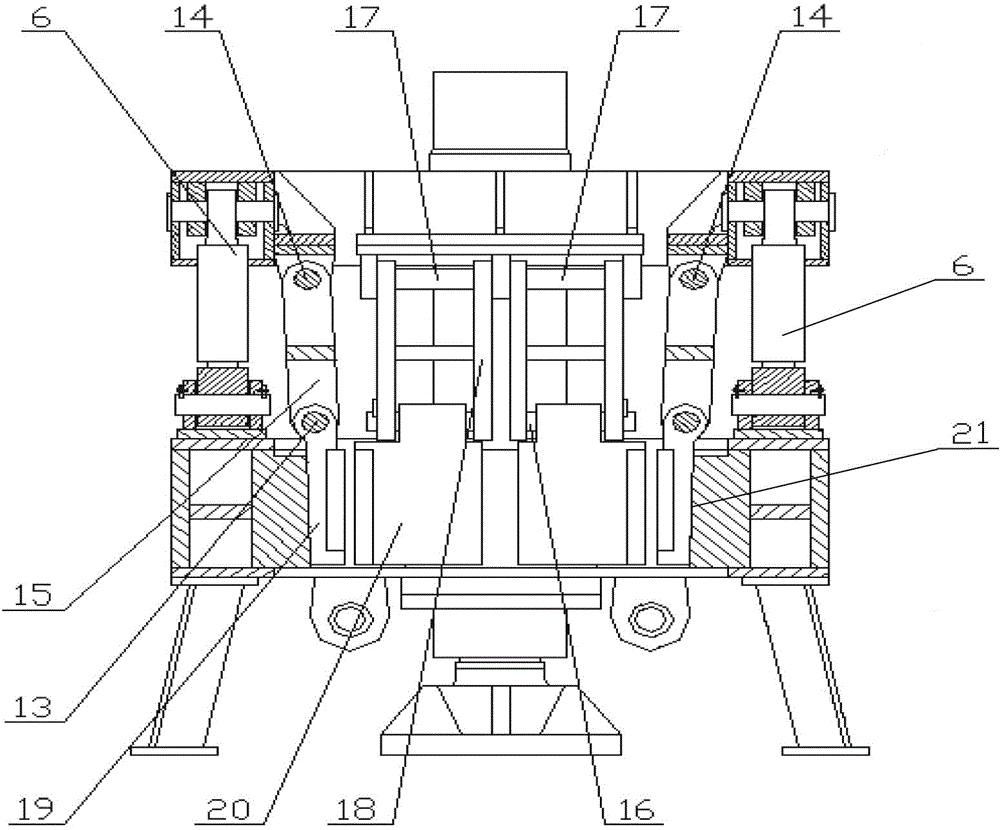

[0022] Figure 1 ~ Figure 3 It is a structural schematic diagram of the H-shaped steel pile lifting machine of the present invention; Figure 4 ~ Figure 5 A schematic structural diagram of the wedge locking device is shown. Image 6 The locking blocks of the wedge locking device are arranged in pairs (or mutually locked, or mutually loosened).

[0023] It can be seen from the figure that the H-shaped steel pile lifting machine includes an upper frame body 7, a lower frame body 4, an initial lifting ring 2, a jacking jack 9 and a load-bearing support 1, which is characterized in that: the jacking The upper end of the lifting jack 9 passes through the steel sleeve and the large fixed guide frame 8 to be integrated with the upper frame body 7, and the lower end passes through the small fixed guide frame 11 set on the lower frame body 4, the steel sleeve and the bearing support 1 connected, and can pass through the steel sleeve of the lower frame body 4 to press down and extend ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com