Cross threads arranged in nut and production process thereof

A thread and nut technology, applied in the field of cross thread and its production process, can solve the problems of complex connection structure, high labor intensity of operators, cumbersome thread screwing process, etc., and achieve the effect of convenient use and enlarged range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

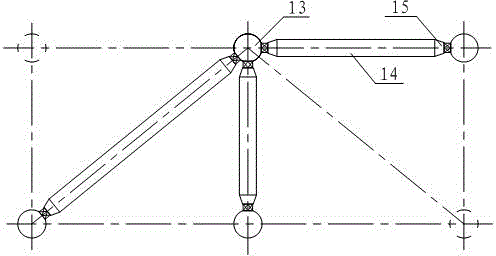

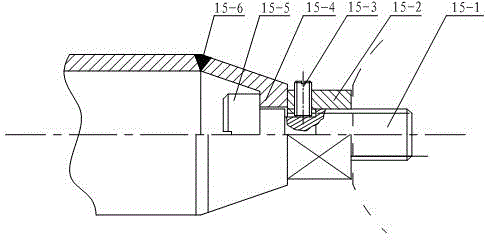

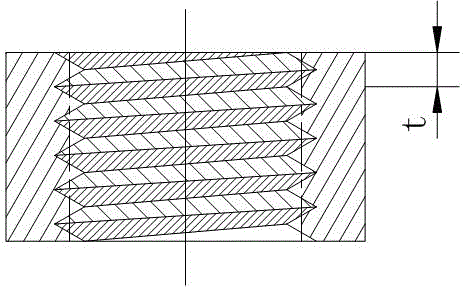

[0073] Such as Figure 5 As shown in the development of the internal thread of the nut, the intersecting thread arranged inside the nut includes a nut body and a through hole arranged along the centerline of the nut body. thread 10, and the two ends of the left-handed thread 11 and the two ends of the right-handed thread 10 are respectively communicated with the two ends of the through hole, the left-handed thread 11 and the right-handed thread 10 are symmetrical along the axis of the through hole, and any left-handed thread 11 The crest of one circle of left-handed thread corresponds to the tooth bottom of one circle of right-handed thread 10 in right-handed thread 10, and the tooth bottom of this circle of left-handed thread corresponds to the tooth crest of this circle of right-handed thread 10. The longitudinal intersection and the transverse intersection between the longitudinal intersection are connected to form a pyramid structure 12, and the edge of the pyramid structu...

Embodiment 2

[0077] A production process of cross threads, in which a through hole is set in the base body, a left-handed thread is processed on the inner wall of the through-hole by a tool, and then a right-handed thread is processed, and the crest line of each left-handed thread is the same as that of the helical line of the same height The bottom lines of the right-handed threads intersect to form several rhombuses, and touch the bottom surface of the right-handed thread to a certain extent. Because the two slopes of the left-handed thread also cut the two slopes of the right-handed thread at the same time, forming four intersecting line edges, Therefore, the finally formed intersecting thread is a plurality of quadrangular pyramid teeth 4 with rhombus bottom surfaces. Since the present invention is mainly used for truss connection equipment, the base body is a nut, and the cutter generally adopts a screw tap. A tap, also called a tap, is a tool for machining internal threads with groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com