front body structure

A technology for the front of the vehicle body, the front and rear of the vehicle body, applied in the directions of the upper structure, the lower structure, the upper structure sub-assembly, etc., can solve the problems such as the inability to fully absorb the impact energy, the inability to buckling and deform the front frame, and achieve a firm support. , the effect of increasing energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

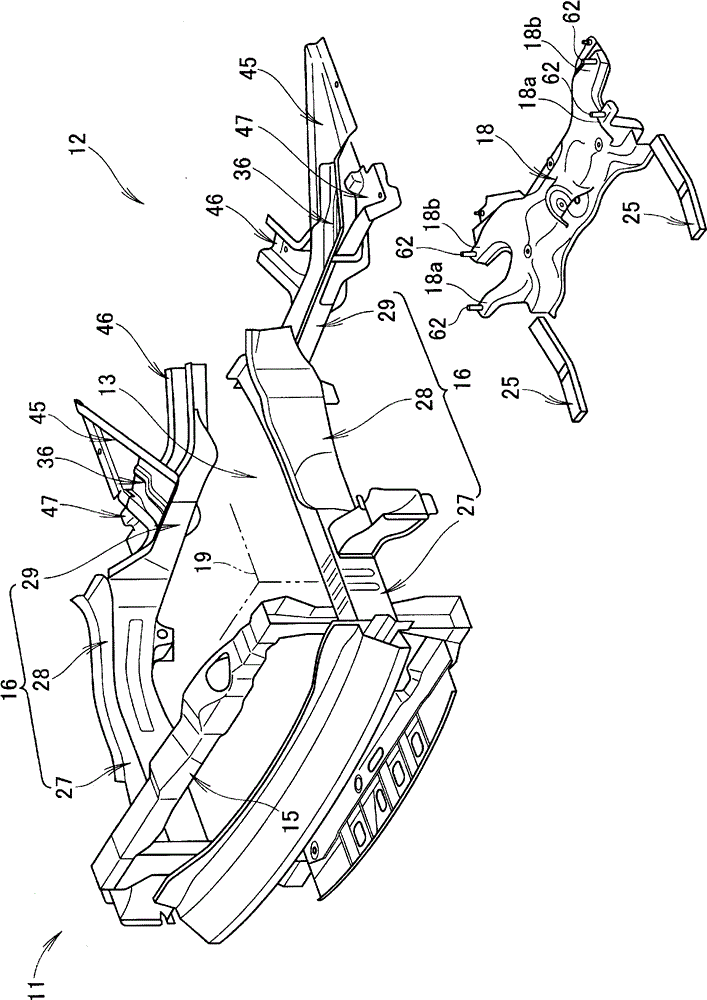

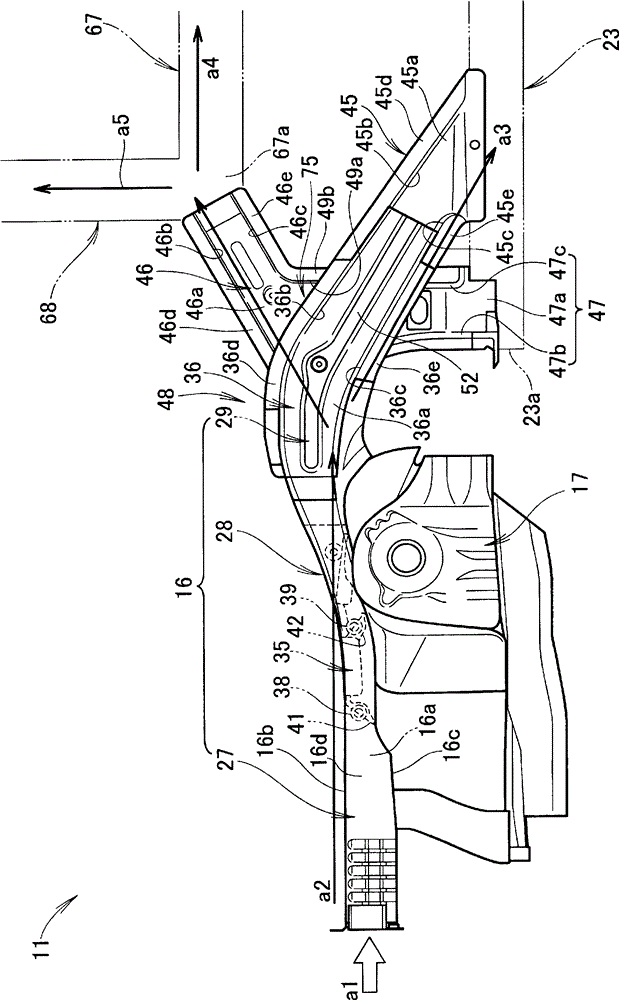

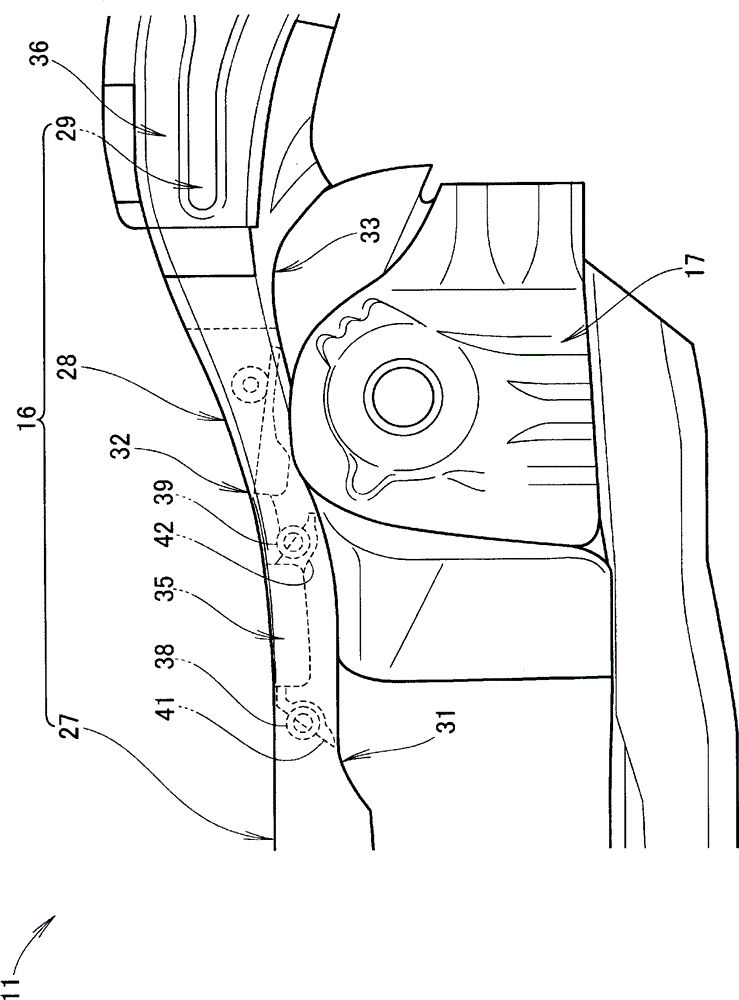

[0066] Such as Figure 1 to Figure 8 As shown, the front structure of the vehicle body in this embodiment includes: a front bulkhead 15 arranged in front of the vehicle body 11; a front side frame 16 extending from the front bulkhead 15 to the rear of the vehicle body; The shock absorber housing 17 in the middle of the vehicle width outside; the subframe (front subframe) 18 supported on the front side frame 16; the rear part of the front side frame 16, and the engine compartment 13 and The instrument panel lower panel 21 ( Figure 4 ); the base plate 22 ( Figure 4 ); at the rear of the instrument panel lower panel 21 and on the side of the bottom plate 22 along the front and rear direction of the vehicle body; Channel part 24.

[0067] The front side frame 16 is composed of a straight portion 27 in which the front portion is linearly extended in the front-rear direction of the vehicle body, a curved portion 28 in which the middle portion is bent in the vehicle width direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com