Lifting equipment

A technology of equipment and lifting lugs, which is applied in the field of special lifting equipment for gantry cranes, to achieve the effects of reducing dead weight, shortening the shipbuilding cycle, ensuring the quality of sections and lifting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further supplemented with description below in conjunction with the accompanying drawings and specific embodiments.

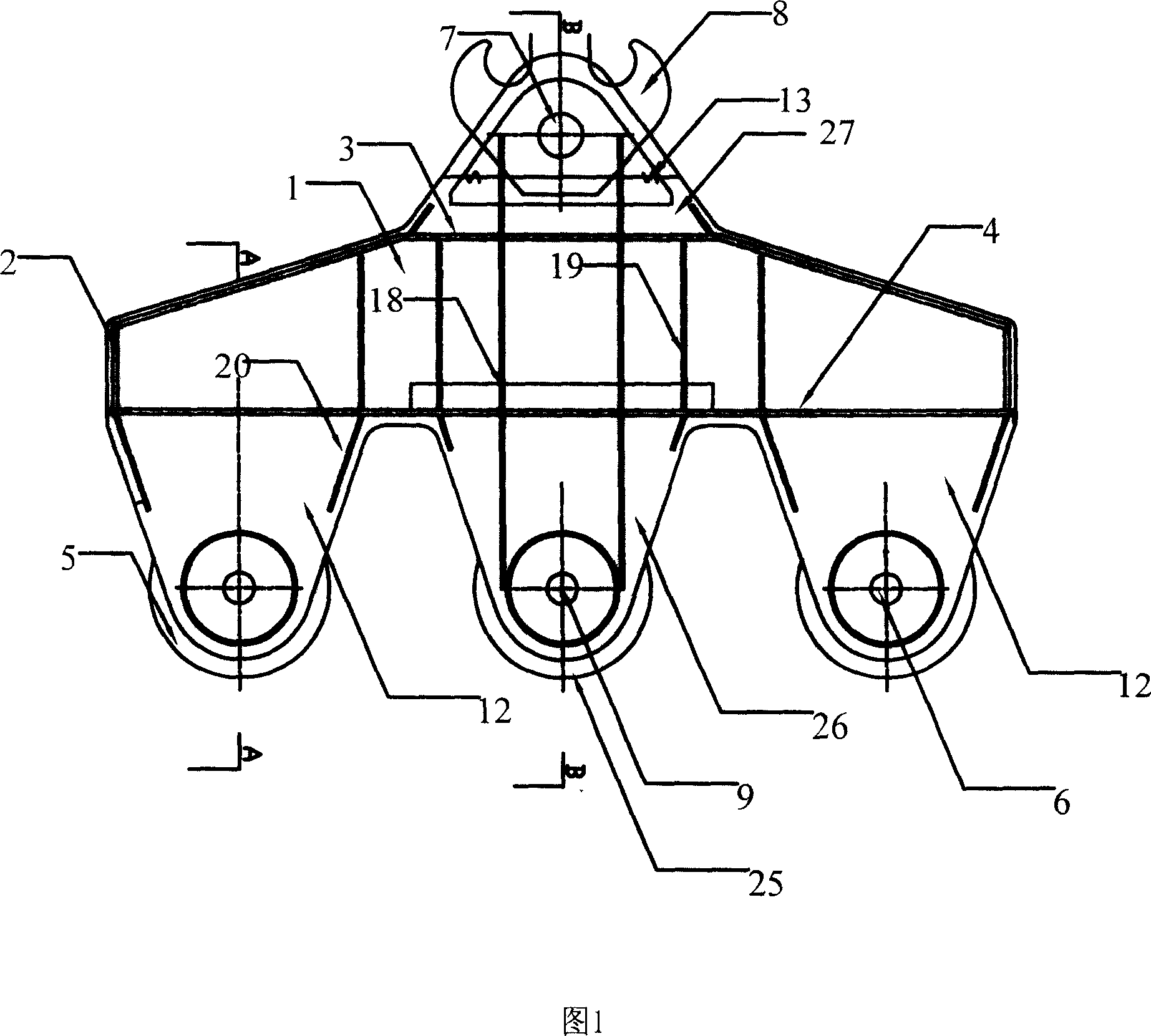

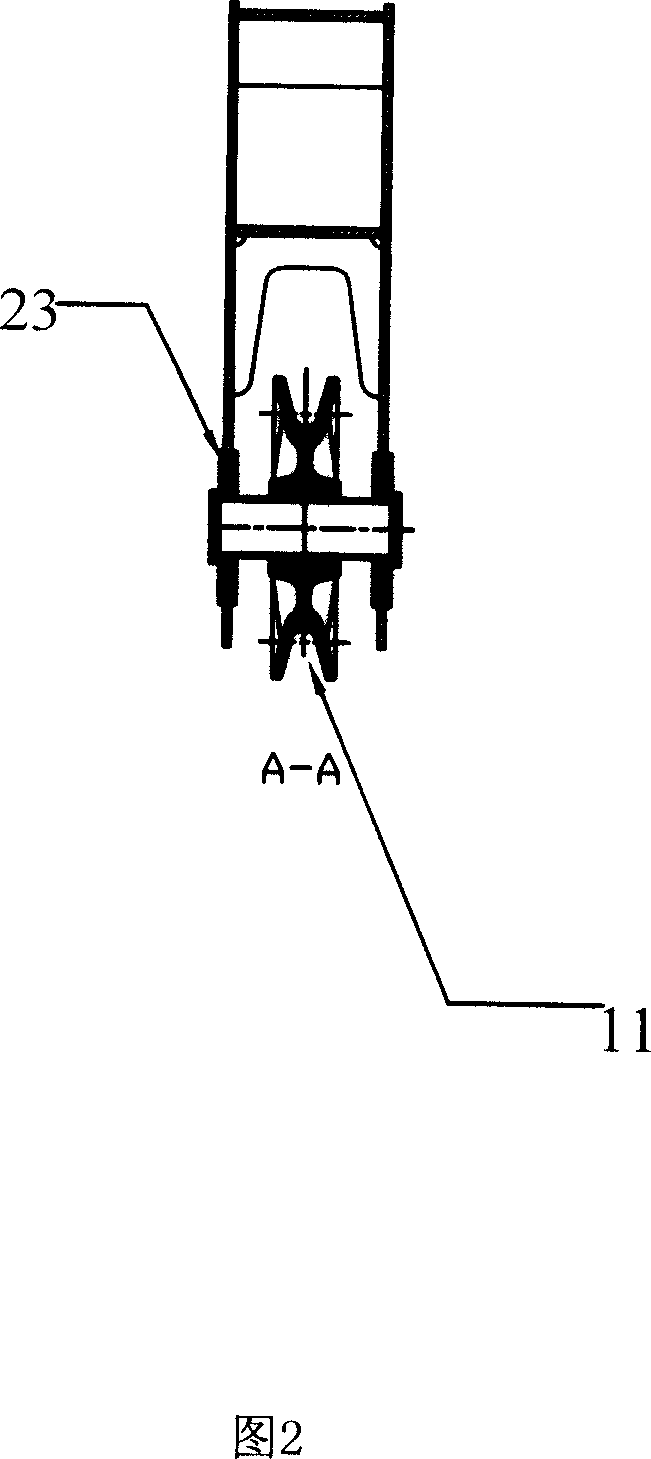

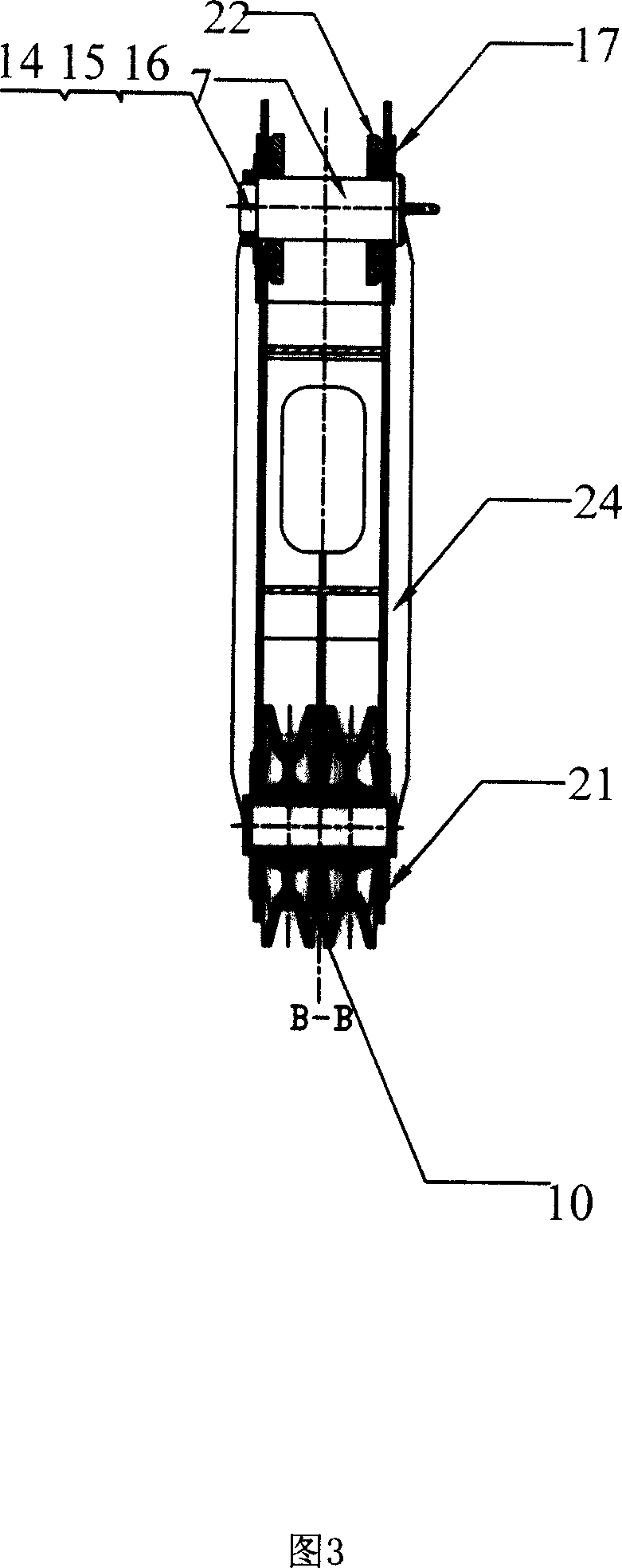

[0026] As shown in Fig. 1 and A-A, B-B sectional view of Fig. 1, promptly Fig. 2, shown in Fig. 3, the implementation of the present invention is to form the suspension main frame structure by web 1, end plate 2, top plate 3, bottom plate 4, and according to above-mentioned The reinforced structure of the hanging row is strengthened. On this basis, pulley 25 and pulley shaft 9 are installed. Single pulley 5 is installed in both sides, is single pulley train 11, sees the A-A sectional view of Fig. 1. Double pulley is installed in the middle, is double pulley train 10, sees the B-B sectional view of Fig. 1. During work, the hanging row is installed and connected with the suspension hook 8 by the lifting trunnion 7, and the wire rope is installed on the pulleys 5, 25. According to the difference of the working conditions, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com