Positioning method for inverting blast furnace shell

A blast furnace shell and positioning method technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as being placed in the furnace frame, failure to lift the furnace belt, and limited driving height on the top of the blast furnace, so as to reduce construction costs, The effect of speeding up the construction progress and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

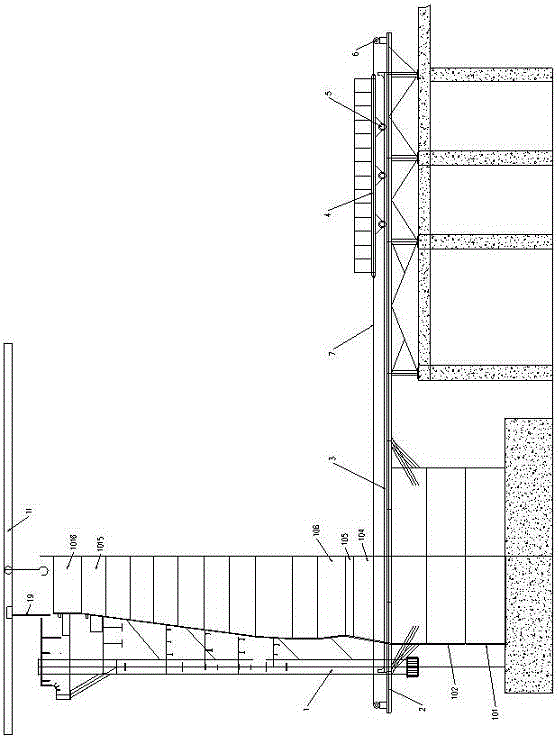

[0021] see figure 1 , remove part of the platform at the tuyere platform on the lower side of the furnace frame 1 as the opening of the furnace shell transportation channel, and install a temporary moving platform on which there are two parallel moving parts extending horizontally into the furnace frame Beams 2, the distance between two moving beams 2 is greater than the maximum diameter of the blast furnace. A track 3 is arranged on the push beam, and the push cart 4 is rolled on the track by the roller 5 at the bottom. The car is connected.

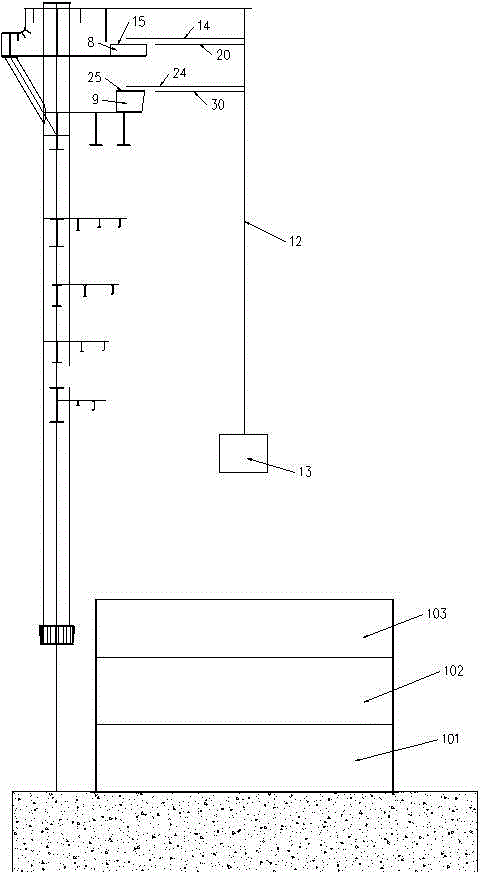

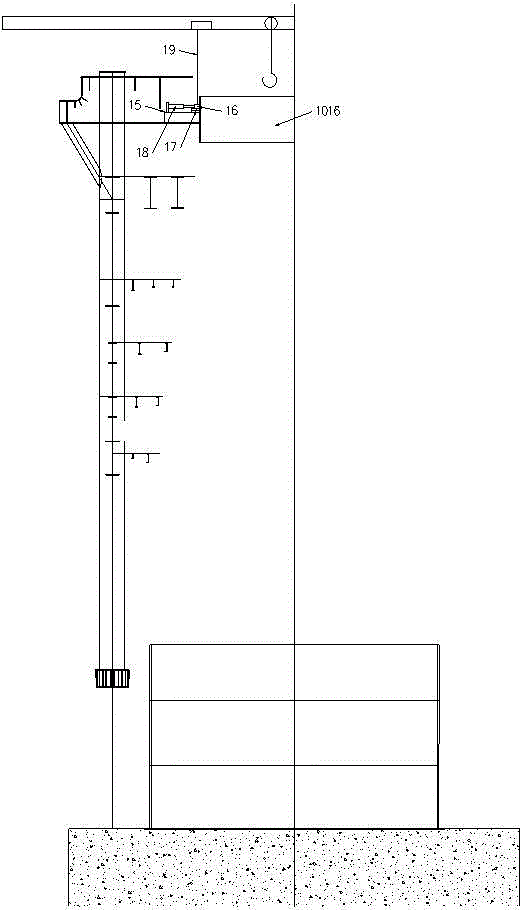

[0022] The furnace shell is composed of 16 furnace belts from bottom to top, which are sequentially composed of the first furnace belt 101, the second furnace belt 102,..., and the sixteenth furnace belt 1016.

[0023] The method of combining the upside down and the upside down of the blast furnace sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com