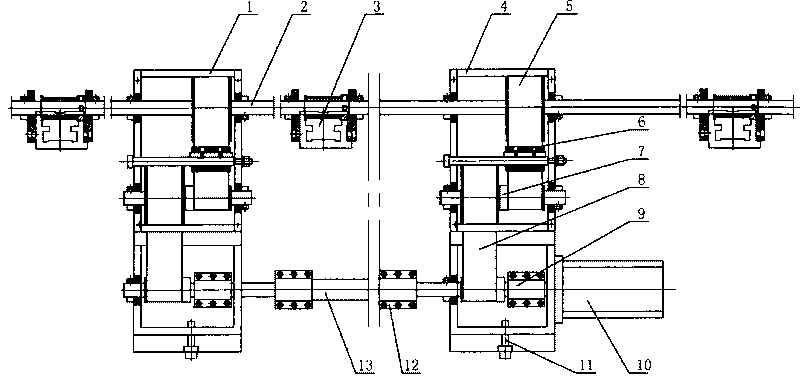

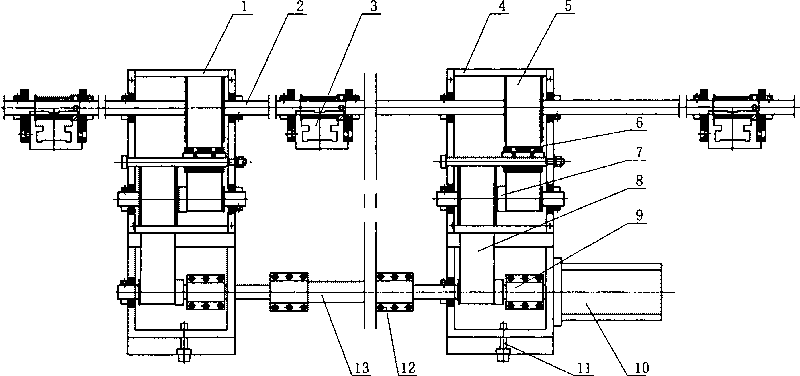

Y-direction servo drive mechanism of overlong stand for computerized embroidery machine

A servo-driven, embroidery machine technology, applied in the direction of embroidery machine mechanism, embroidery machine, textile and paper making, etc., to ensure the transmission accuracy, ensure the quality of the embroidery, and ensure the smooth transmission effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

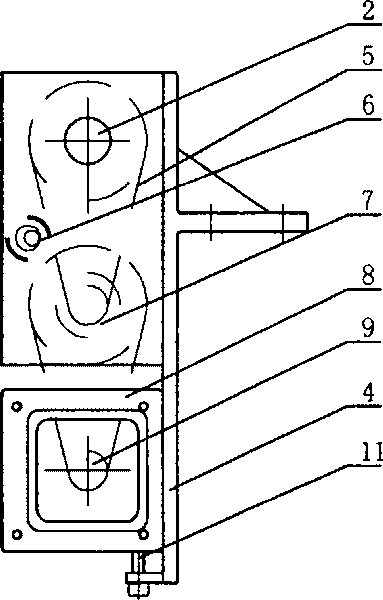

[0015] A super-long frame Y-direction servo drive mechanism of a computerized embroidery machine, comprising a Y-direction main drive mechanism and a Y-direction cloth feeding mechanism driving shaft 2, on which a Y-direction cloth feeding mechanism The driving mechanism is composed of a servo motor 10, a main frame 4, a main timing belt 8, and an auxiliary timing belt 5. The servo motor drives the main timing belt through its output shaft 9, and the main timing belt drives the auxiliary timing belt through an intermediate toothed pulley 7. The synchronous belt drives the driving shaft to make the driving shaft rotate, thereby driving the Y-direction cloth feeding mechanism to work. In order to impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com