Cloth fixing mechanism on embroidery frame of embroidery machine

A technology for fixing mechanisms and embroidery machines, which is applied to the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc. It can solve the problems of affecting work efficiency, reducing the service life of driving guide rails, and reducing the qualified rate of products, so as to achieve a compact and reasonable overall structure. , reduce the overall weight, the effect of compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

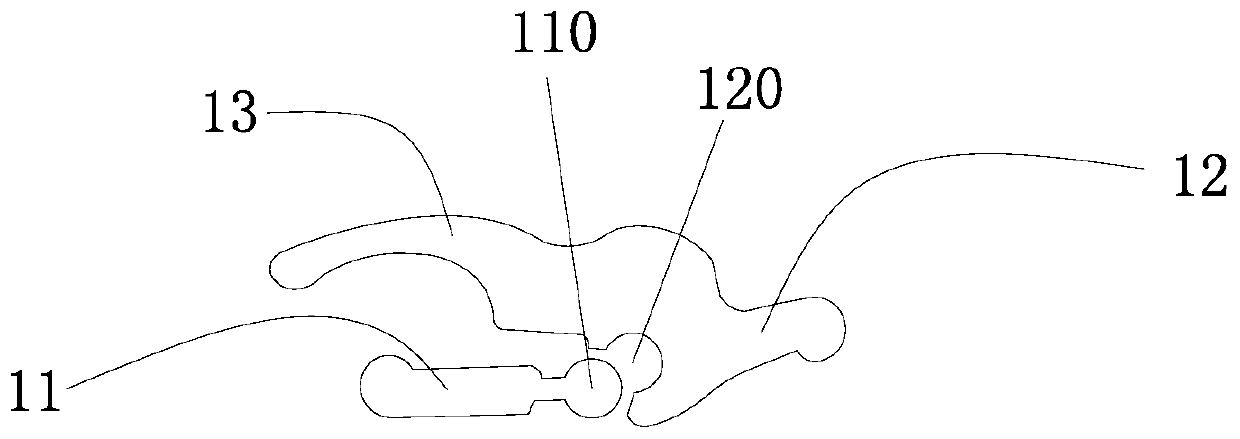

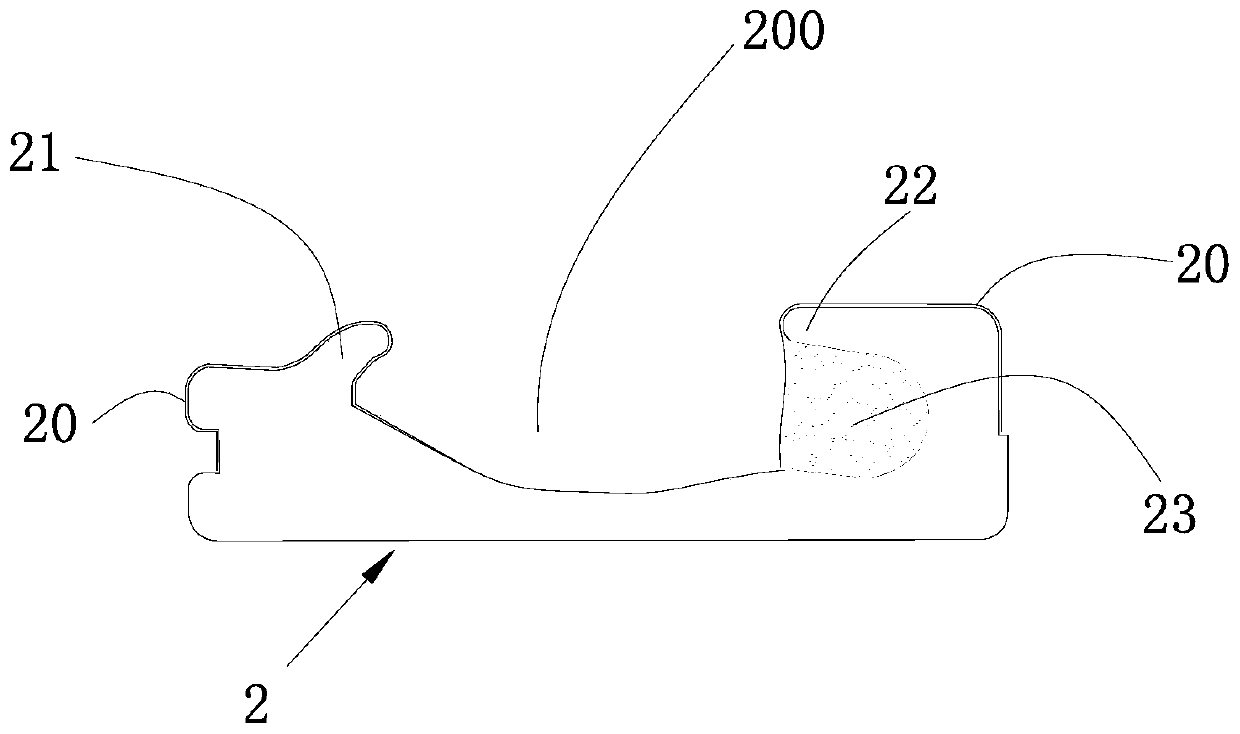

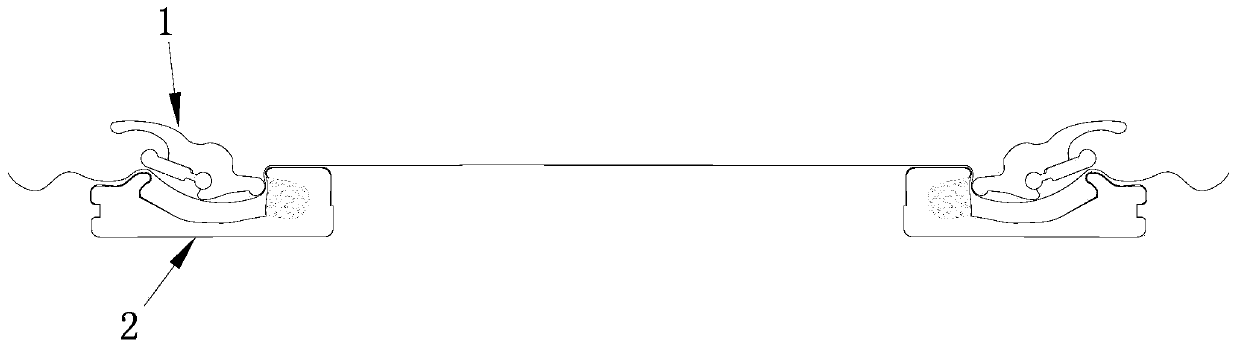

[0027] Such as Figure 1 to Figure 5 As shown, a cloth fixing mechanism on the embroidery frame of an embroidery machine, the fixing mechanism includes a fixing holder 2 which is fixedly connected to the embroidery frame and has an opening slot 200, and a card capable of cooperating with the opening slot 200 and fixing the cloth Connecting assembly 1, a first blocking portion 21 and a second blocking portion 22 are formed on both sides in the width direction of the opening of the opening slot 200. Two clamping bodies 12 , the free sides of the first clamping body 11 and the second clamping body 12 can be in contact with the first blocking portion 21 and the second blocking portion 22 respectively. In this example, the materials of the fixed card base 2 and the clamping component 1 are both made of aluminum alloy, and the overall weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com