Auxiliary molding device capable of detecting tensile strength of reinforced concrete

A technique for reinforced concrete, tensile strength, used in the preparation of test samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

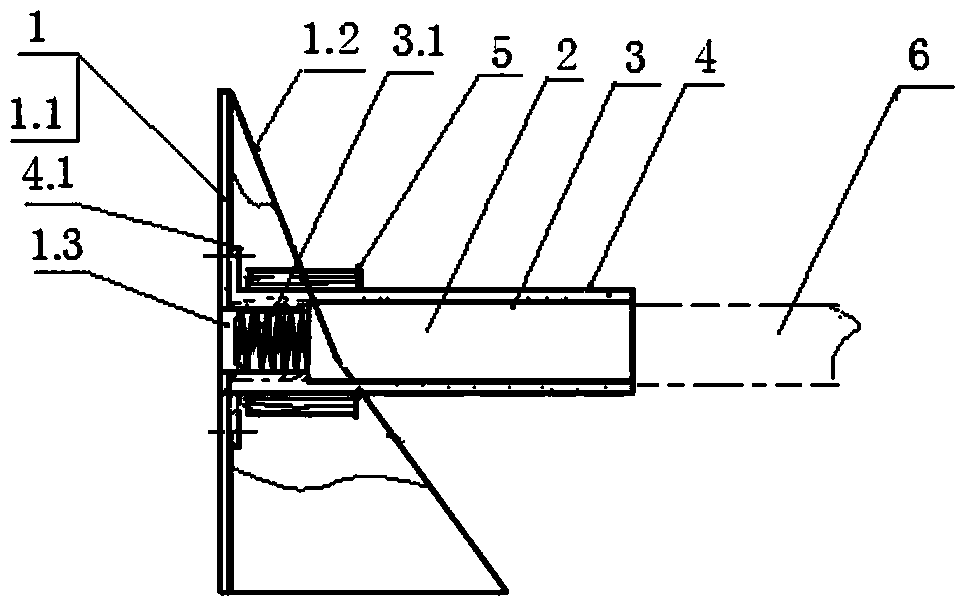

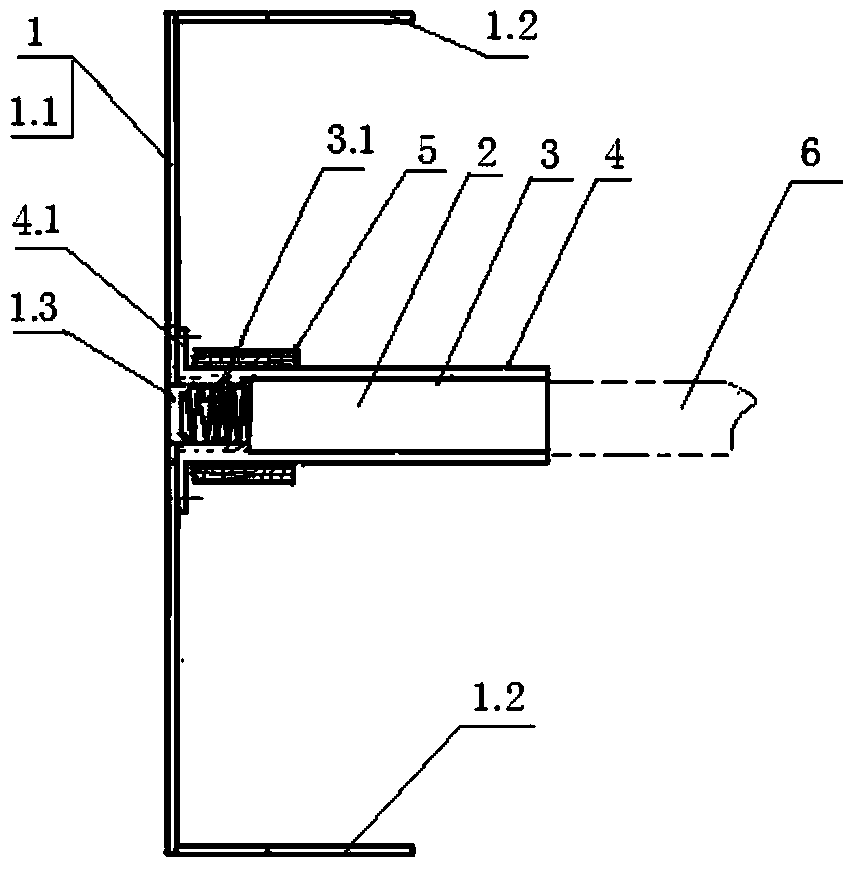

[0033] Example 1 : is a basic embodiment. Such as figure 1 , 2 , 3 and 4, the auxiliary forming device for testing the tensile strength of reinforced concrete is composed of two symmetrical single-piece devices, each single-piece device includes a supporting member 1 and can adjust the axial displacement of the steel bar with the supporting member 1 Fixedly connected steel bar positioning component 2, the steel bar positioning component 2 is a rotating telescopic metal sleeve; the support member 1 is composed of a main board 1.1 and a side plate 1.2; a plurality of equidistant circular connection holes are symmetrically arranged on the main board 1.1 1.3, used for positioning and fixing the steel bar positioning assembly 2; there are two side plates 1.2, which are respectively fixed on both sides of the main board 1.1; the steel bar positioning assembly 2 includes an inner cylinder 3, an outer cylinder 4 and an adjustment knob sleeve 5; One end of the inner cylinder 3 by ...

Embodiment 2

[0034] Example 2 : is a further embodiment. The main board 1.1 of the auxiliary forming device for testing the tensile strength of reinforced concrete is rectangular or isosceles trapezoidal or circular. The main board 1.1 is positioned and fixed by the fixing flange 4.1 on the end surface of the outer cylinder 4 with screws and the reinforcing bar positioning assembly 2 . The main board 1.1 of the supporting member 1 has a plurality of connection holes 1.3, which can be connected with a plurality of steel bar positioning components 2 for testing the tensile strength of multi-reinforced concrete. The cushion layer in the inner cylinder 3 is a cushion layer made of compressible elastic material such as sponge layer or soft rubber layer or foam, which is used to detect and limit the tensile strength of steel bars with different diameters.

Embodiment 3

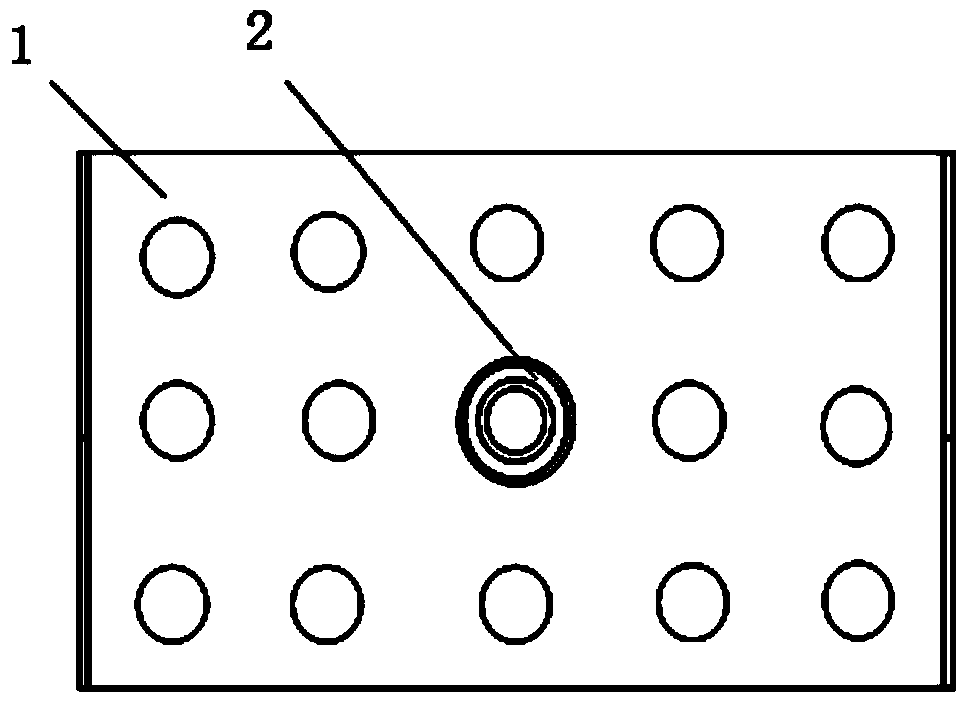

[0035] Example 3 : is a further embodiment. Such as image 3 As shown, there is 1 set of auxiliary forming device for detecting the tensile strength of reinforced concrete according to the present invention. The main board 1 is rectangular, and there are three rows on it, each row has 5, a total of 15 connection holes 1.3, and the present embodiment is equipped with a central part A reinforcing bar positioning component 2 is installed in the connection hole 1.3; the main board 1.1 is 196mm long and 100mm wide. The steel bar positioning assembly 2 is 80mm long, wherein the outer cylinder 4 is 80mm long, with an outer diameter of 30mm and an inner diameter of 26mm; the inner cylinder 3 is 30mm long, with an outer diameter of 25mm and an inner diameter of 22mm, and the threaded rod 3.1 is 40mm long.

[0036] When testing, such as Figure 4 As shown, the two ends of the steel bar 6 to be embedded are respectively inserted into the inner cylinder 3 of the auxiliary forming devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com