Efficient cutting type side cross beam cutting-off equipment for low-voltage switch cabinet

A technology for low-voltage switchgear and cutting equipment, which is applied in the direction of switchgear, shearing equipment, metal processing equipment, etc., and can solve the problems of low-voltage switchgear side beams being loosely fixed, affecting the efficiency and accuracy of cutting, and cutting off. Achieve the effect of improving the flexibility of use, convenient maintenance, and avoiding loosening and offsetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

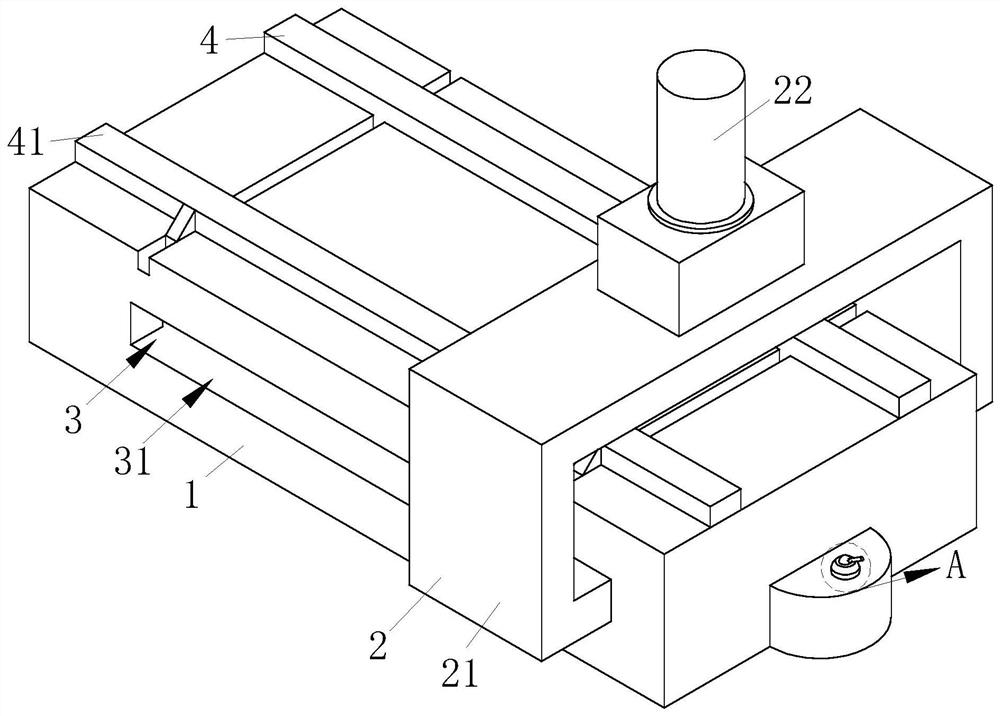

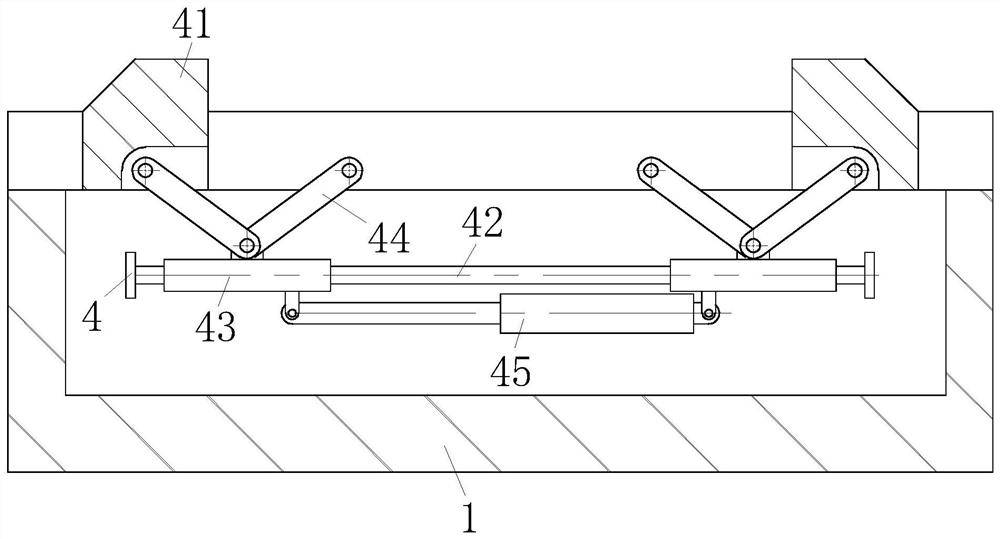

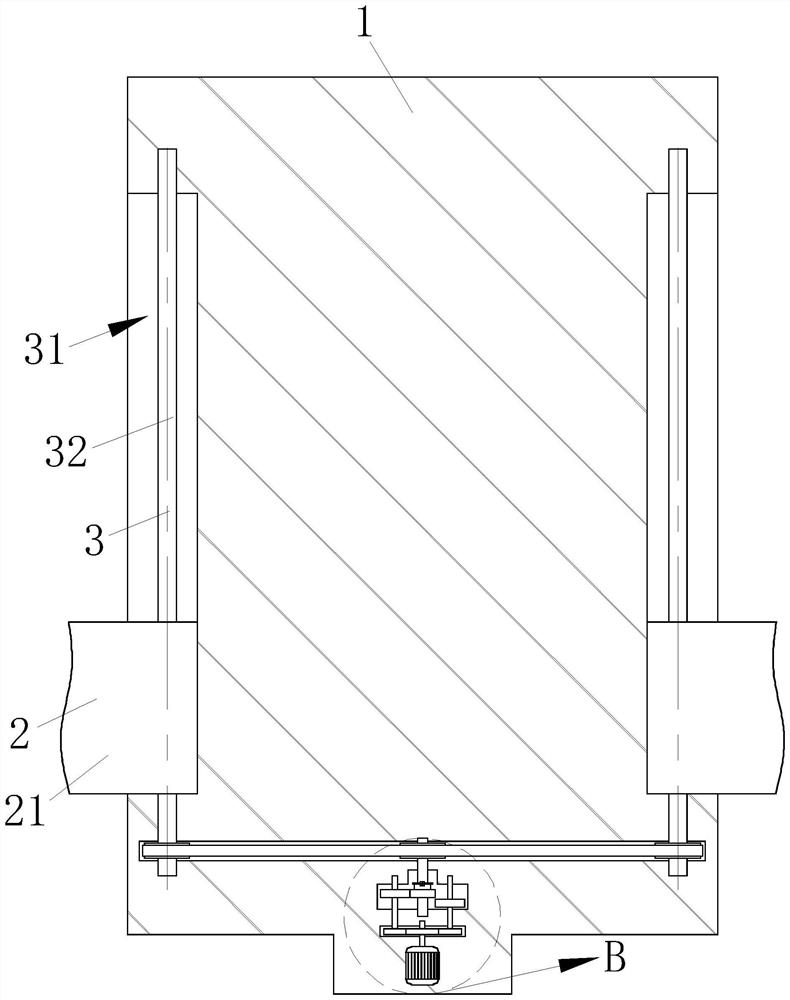

[0026] Such as Figure 1-Figure 8 As shown, a kind of high-efficiency cutting side beam cutting equipment for low-voltage switchgear according to the present invention includes a main body 1, a cutting mechanism 2, a moving mechanism 3, a clamping mechanism 4, a rotating mechanism 5 and a switching mechanism 6, for utilizing The cutting mechanism 2 for hydraulically cutting the beam is arranged on the top of the main body 1, and the moving mechanism 3 for driving the cutting mechanism 2 to move is arranged inside the main body 1, and is used to clamp and fix the beam. The clamping mechanism 4 is arranged inside the top end of the main body 1, the rotating mechanism 5 for providing power for the moving mechanism 3 is arranged inside the main body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com