Mining explosive-proof electromotor anti-explosion reducing valve

A technology of explosion-proof motors and pressure reducing valves, which is applied in the direction of engine components, safety valves, balance valves, etc., can solve the problems of reducing the service life of motors, motor operation and safety threats, and achieves high economy, significant decompression effect, Effect of improving safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is specifically described below in conjunction with accompanying drawing:

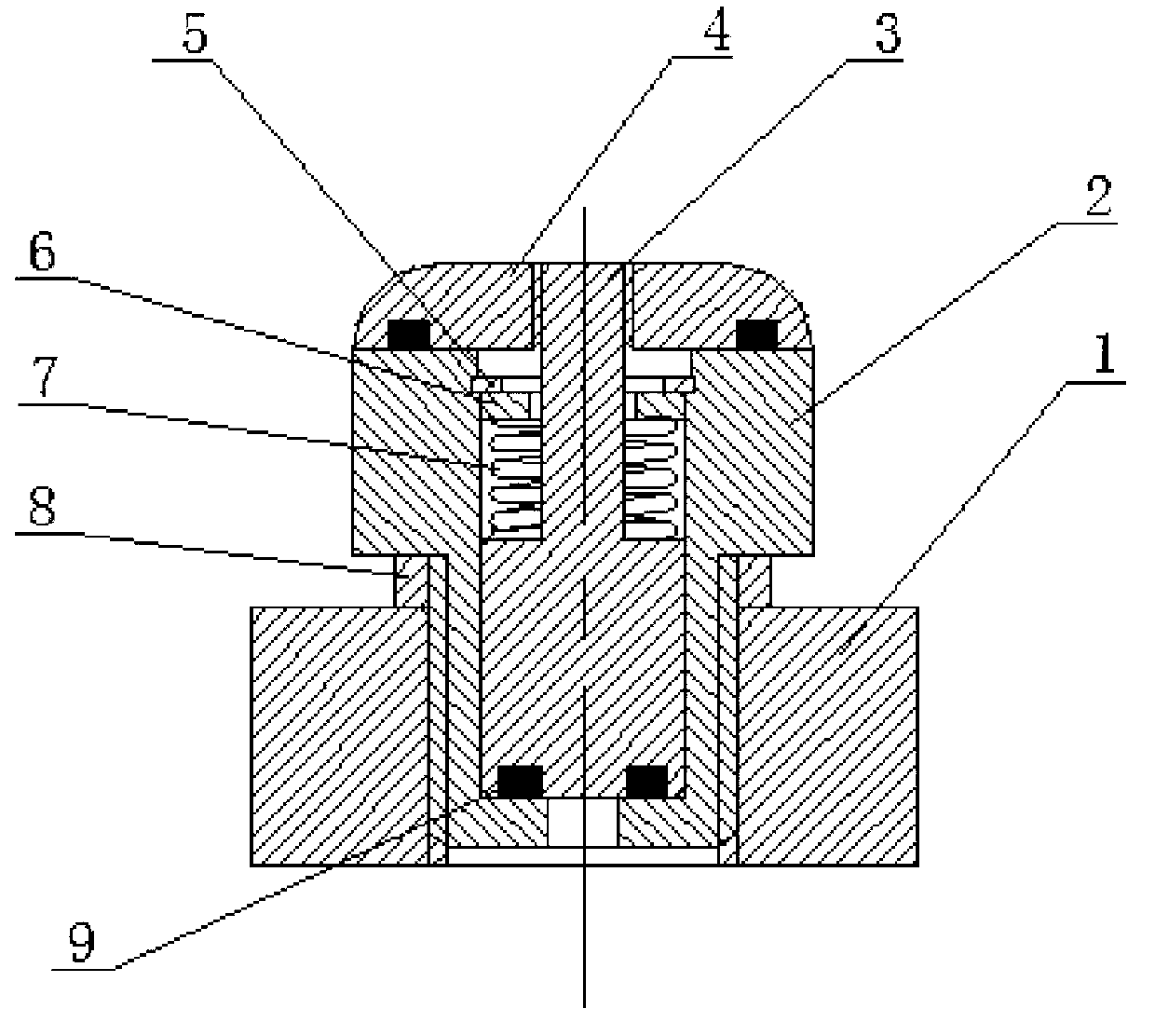

[0009] Such as figure 1 As shown, it is a structural schematic diagram of the mine explosion-proof motor explosion-proof decompression valve of the present invention, including a valve housing 1, a valve body 2, a valve core 3, a valve cap 4, a retaining ring 5, a flat washer 6, a compression spring 7, and an industrial leather Sealing ring 8, O-shaped sealing ring 9; the valve housing 1 is welded on the casing of the penetrating motor base and communicates with the inner cavity of the motor. For the installation of the pressure reducing valve, the lower part is processed with explosion-proof external threads for tightly matching the valve casing 1; the mating surface of the valve body 2 and the end surface of the valve casing 1 is sealed with an industrial leather sealing ring 8 to increase its sealing performance. The inner side of the valve body 2 and the valve core 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com