Paint bucket cleaning system

A cleaning system and automatic cleaning technology, which is applied in the field of its mechanical connection structure and paint canister cleaning system, can solve the problems of reducing cleaning costs and large labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

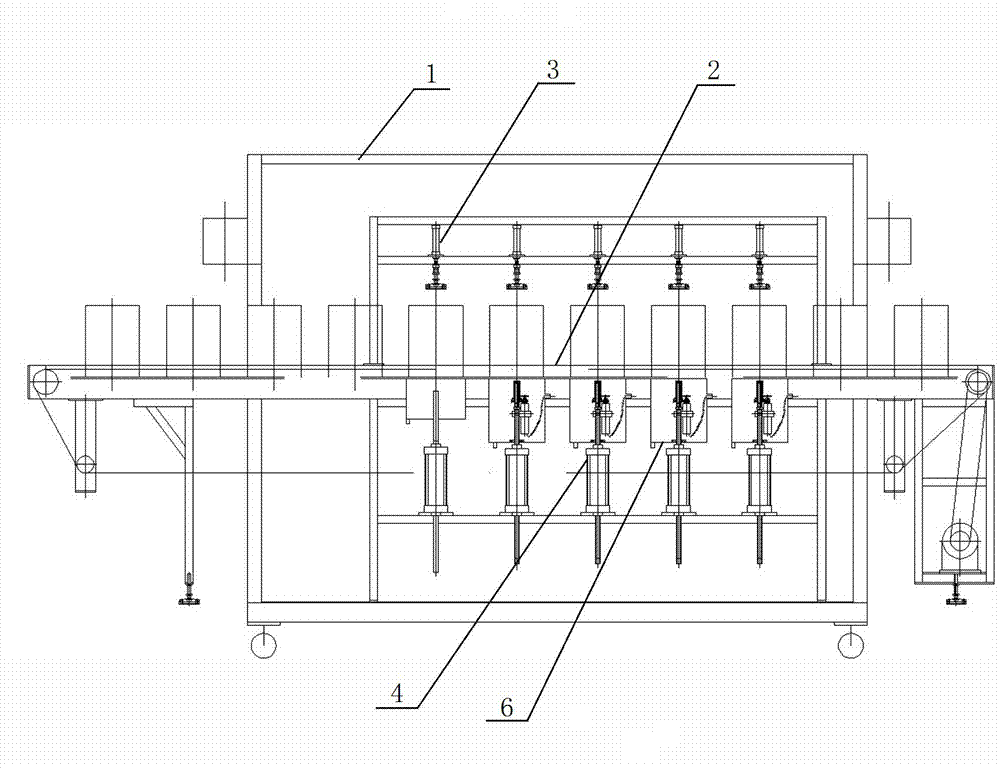

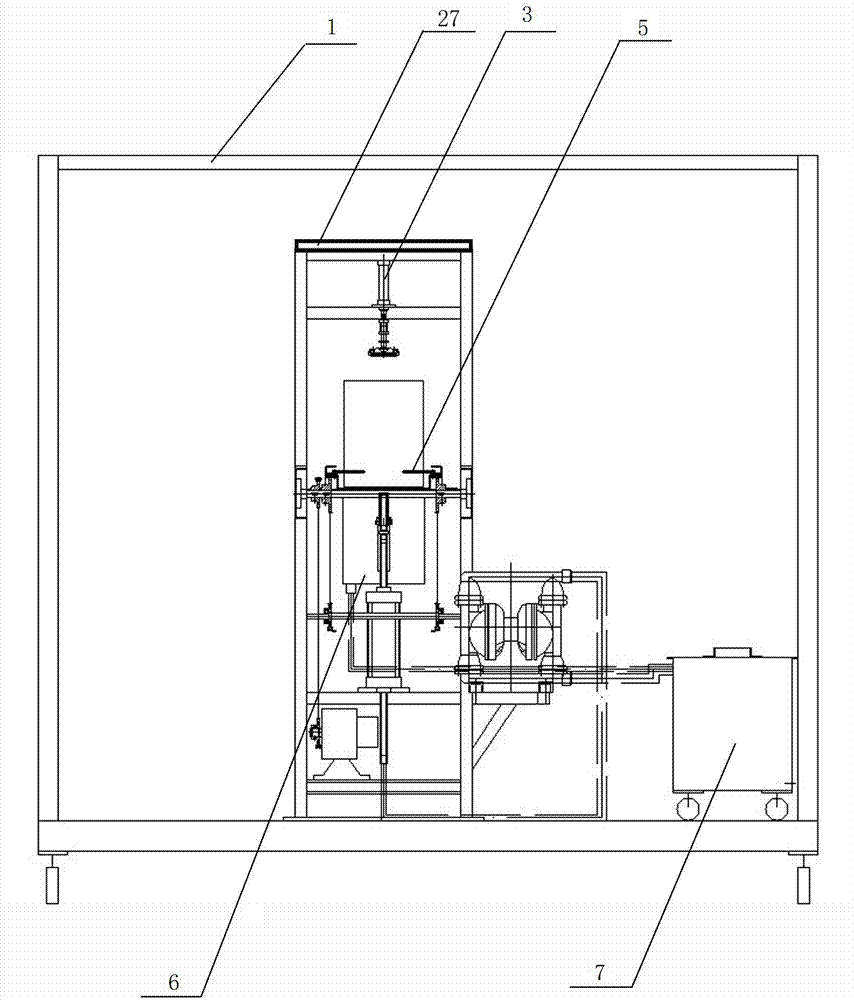

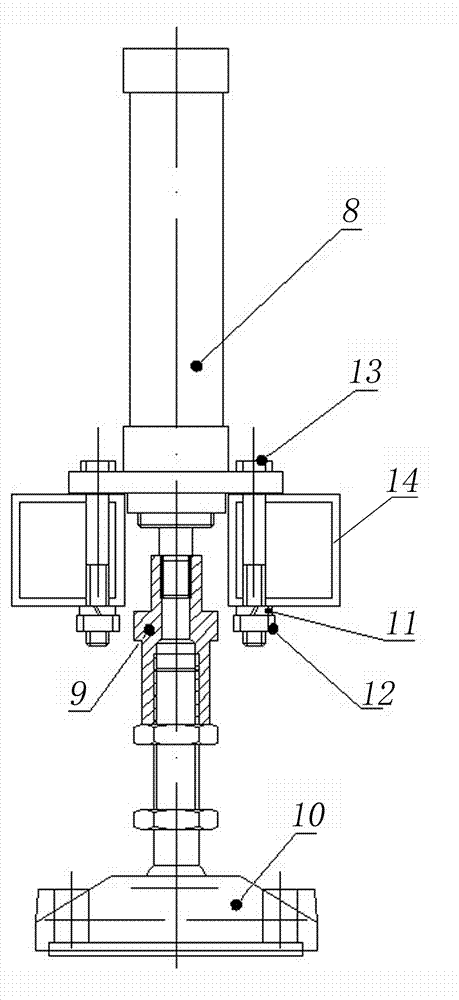

[0014] The invention discloses a paint canister cleaning system, which includes an isolation cabin 1, which is different from the prior art in that: the isolation cabin 1 is provided with an automatic cleaning conveyor belt 2, and the upper part of the automatic cleaning conveyor belt 2 is provided with an upper gland Device 3, the lower part of the automatic cleaning conveyor belt 2 is equipped with a lifting rotary spray device 4, which is connected to the organic solvent storage container 7, and a ventilation device 28 is provided at the isolation compartment 1.

[0015] In a specific implementation, an organic solvent filtering device is provided between the lifting rotary spraying device 4 and the organic solvent storage container.

[0016] In a specific implementation, the above-mentioned ventilation device is an air inlet pipeline and an exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com