Powder surface cleaning equipment and cleaning method

A surface cleaning and powder technology, applied in the field of materials, can solve the problems of large powder loss, reduced filtration rate, complicated operation, etc., and achieve the effects of reducing anions and cations, high cleaning efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

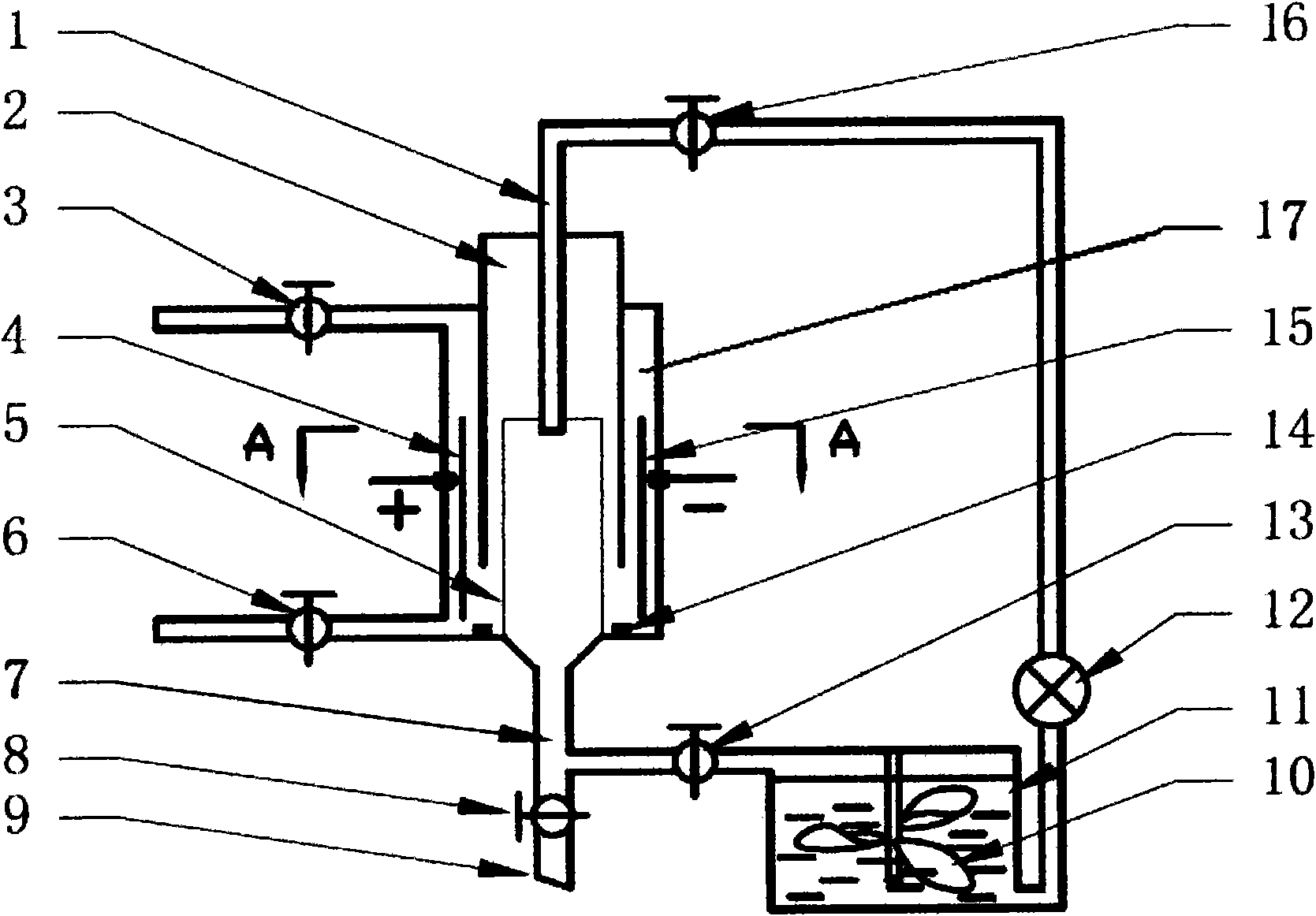

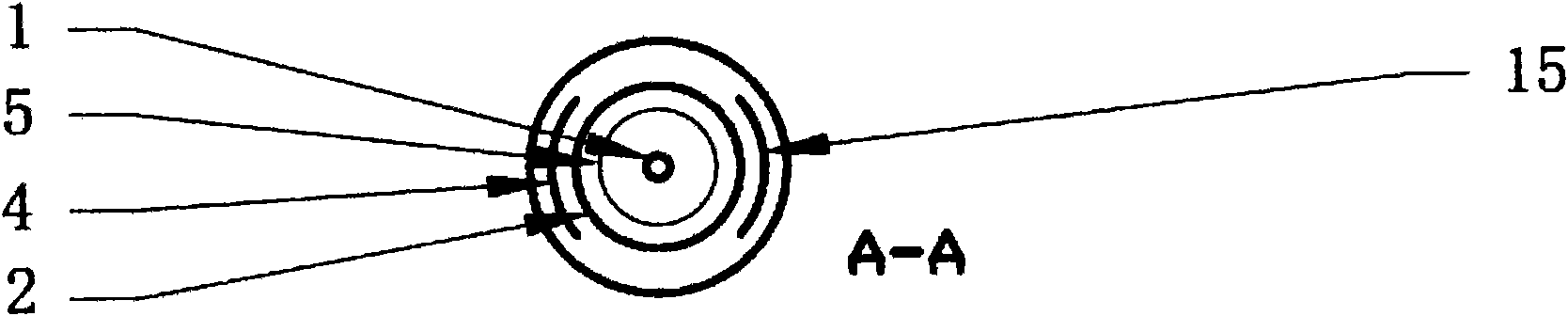

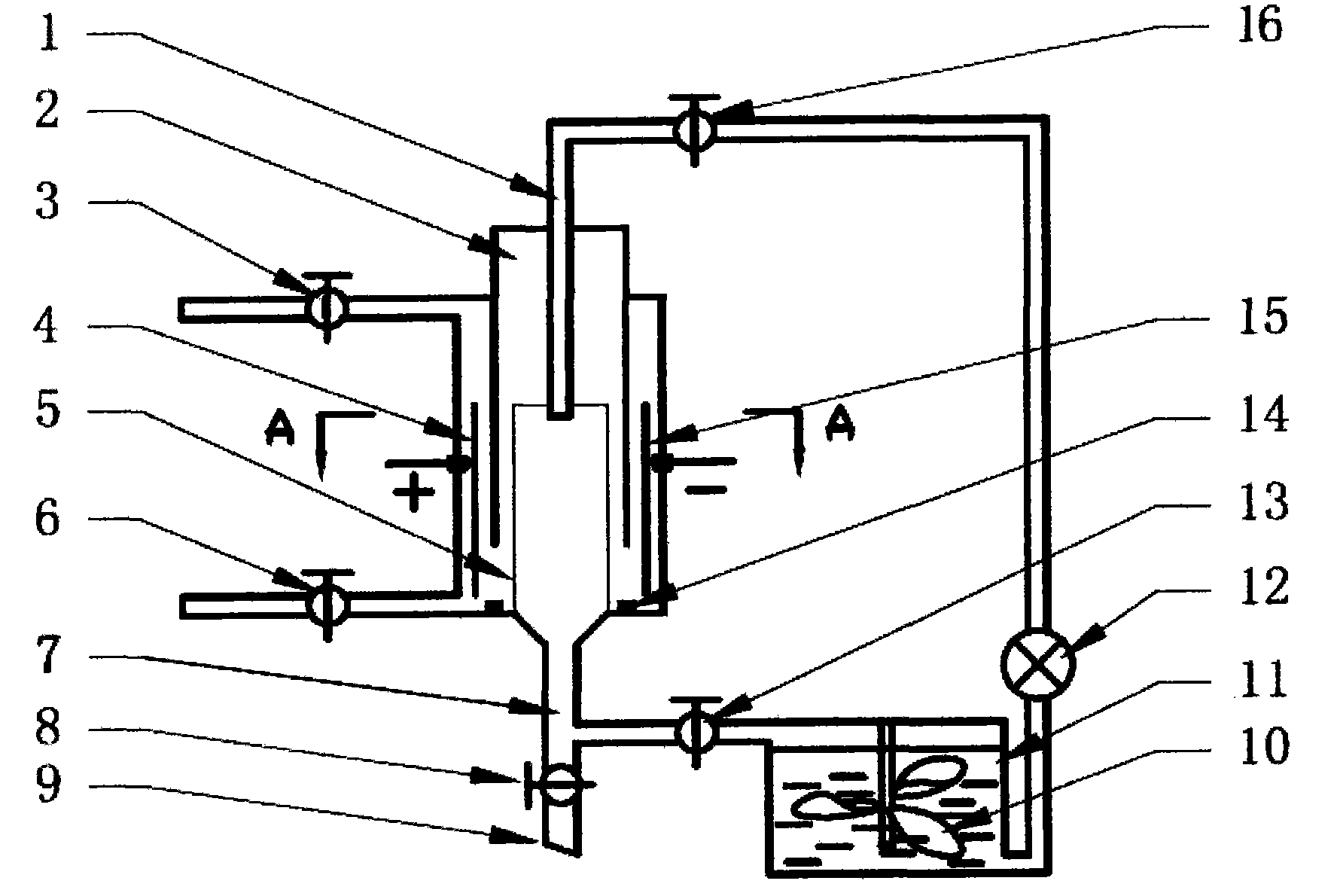

Method used

Image

Examples

Embodiment 1

[0029] to deal with attached Na 2 CO 3 submicron Al 2 o 3 powder (average particle size 1μm) as an example

[0030] Will Al 2 o 3The powder is placed in a circulating water pool with a filter mesh of 300 mesh, and the ultrapure water is introduced into the container space outside the tubular filter of the circulating cleaning equipment, so that the powder is placed in flowing water, and the conductivity of the water used is 10μs / cm. Then apply a voltage of 200 volts on both sides of the container to form an electric field on both sides of the container. Let the powder circulate through the electric field with the water flow, put down the metal sleeve after 5 minutes and place it between the filter screen and the electrode, and connect it with the sealing ring, then stop the water pump and cancel the electric field, and discharge the water flow between the electrode and the metal sleeve Walk. Open the water inlet valve, then introduce ultrapure water into the container s...

Embodiment 2

[0032] Take the treatment of nano-TiC powder (average particle size 10nm) attached with NaCl as an example

[0033] Put the TiC powder in the circulating water pool, the filter mesh is 600 mesh, introduce the ultrapure water into the container space outside the tubular filter of the circulating cleaning equipment, put the powder in the flowing water, and the conductivity of the water used is 15μs / cm. Then apply a voltage of 400 volts on both sides of the container to form an electric field on both sides of the container. Let the powder circulate through the electric field with the water flow, put down the metal sleeve after 10 minutes, place it between the filter screen and the electrode, and connect it with the sealing ring, then stop the water pump and cancel the electric field, and discharge the water flow between the electrode and the metal sleeve Walk. Open the water inlet valve, then introduce ultrapure water into the container space outside the tubular filter, and cl...

Embodiment 3

[0035] Take the treatment of diamond powder with KCl attached (average particle size is 100μm) as an example

[0036] Put the diamond powder in the circulating water pool, the filter mesh is 50 mesh, introduce the ultrapure water into the container space outside the tubular filter of the circulating cleaning equipment, put the powder in the flowing water, and the conductivity of the used water flow is 10μs / cm. Then apply a voltage of 400 volts on both sides of the container to form an electric field on both sides of the container. Let the powder circulate through the electric field with the water flow, put down the metal sleeve every 10s and place it between the filter screen and the electrode, and connect it with the sealing ring, then stop the water pump and cancel the electric field, and the water flow between the electrode and the metal sleeve row away. Open the water inlet valve, then introduce ultrapure water into the container space outside the tubular filter, and clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com