Oil seed roasting machine sealing pan cover and pan cover opening and closing device

A technology of opening and closing device and seed frying machine, which is applied in the direction of fat oil/fat production and fat generation, which can solve the problems of physical damage to workers, difficulty in automatic unloading, and pollution of the working environment, so as to reduce dust pollution and shorten frying time. The effect of reducing material time and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

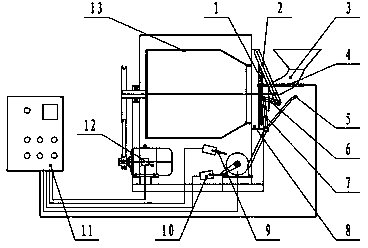

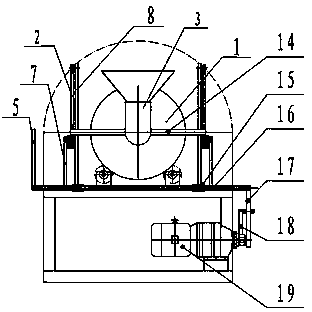

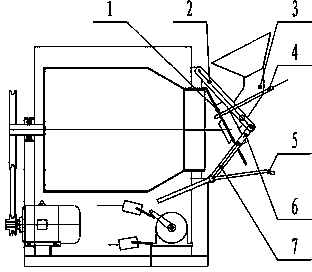

[0025] see figure 1 , figure 2 , image 3 , the oil seed frying machine of the present invention has a closed pot cover and a pot cover opening and closing device, including a pot cover 1 and a feed pipe 3, a hinged four-bar mechanism, a manual operating lever 5, a transmission shaft 16, a shaft push rod mechanism and a pot The electric control part of automatic cover opening, wherein, the center of the pot cover 1 has a hole for feeding the feed pipe 3, and the connection between the feed pipe 3 and the center hole of the pot cover is equipped with a bearing, so that the pot cover 1 It can rotate around the feed pipe 3 and along with the rotation of the frying pan 13 of the seed frying machine drum. The both sides of the feed pipe 3 are symmetrically equipped with a pot lid hinge shaft 14, and the two ends of the pot lid hinge shaft 14 are respectively connected to the pot cover. 1. The hinged four-bar mechanism arranged symmetrically on both sides is flexibly connected. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com