Observation and test apparatus for cavity evolution in test pieces under tensile impact and test method

A test method and cavity technology, which is applied in the direction of testing the strength of materials with a single impact force to achieve the effect of a simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

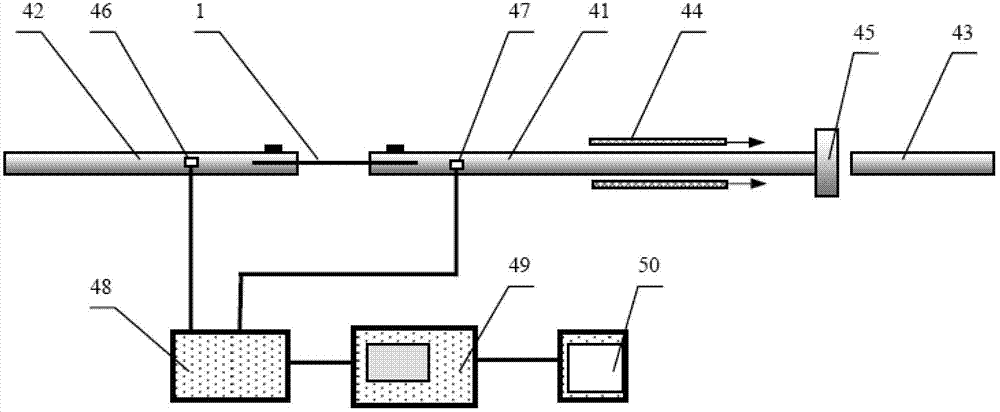

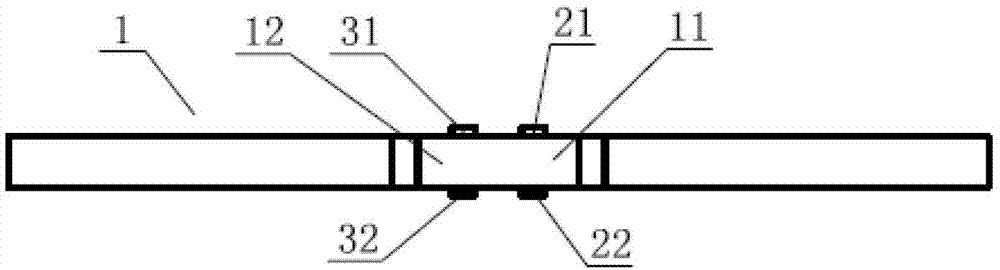

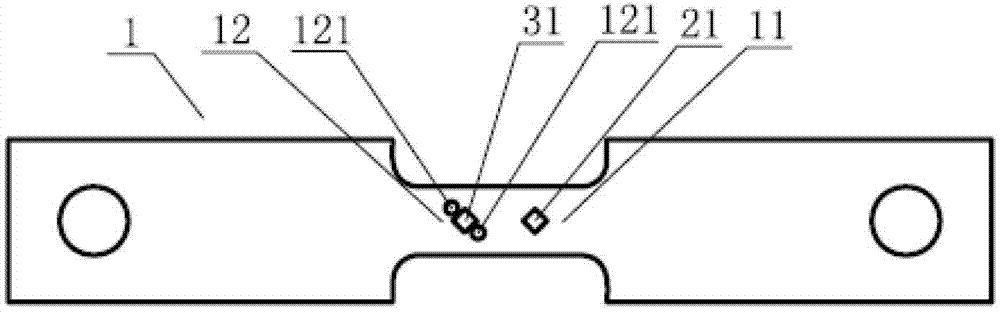

[0023] As shown in the figure, a test device for observing the evolution of voids in a test piece under impact tension includes micro-strain gauges symmetrically arranged on the two surfaces of the strip test piece 1, and the micro-strain gauges include two first micro-strain gauges 21 and 22 and two second micro-strain gauges 31 and 32, the strip test piece 1 includes a non-cavity cluster region 11 and a hole cluster region 12 preset with a plurality of holes 121, and the strip test piece 1 is fixedly installed on Between the input rod 41 and the output rod 42 of the Hopkinson rod device, the non-cavity cluster area 11 is close to the input rod 41, the cavity cluster area 12 is close to the output rod 42, and the two first micro-strain gauges 21 and 22 are arranged on the non-cavity cluster area 12. In the hole cluster area 11, two second mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com