A sensor assembly with bottoming detection

A sensor component, sensor technology, applied in the sensor field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

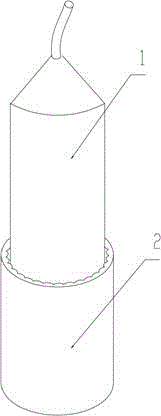

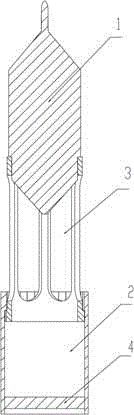

[0030] Such as figure 1 , Figure 5 and Figure 7 As shown, a sensor assembly with bottoming detection includes a sensor assembly 1, the lower part of the sensor assembly 1 is fitted with a slip ring 2 that can slide along the axis of the sensor assembly 1, and the bottom of the slip ring 2 An impact part 4 is provided, and the sensor assembly 1 includes an acceleration sensor.

[0031] The lower part of the sensor assembly 1 and the upper part of the slip ring 2 are provided with a limit snap ring 5 .

[0032] The sensor assembly 1 further includes a dielectric constant sensor, a temperature sensor, a pressure sensor or / and a Ph value sensor combined with the acceleration sensor.

[0033] The slip ring 2 is made of stainless steel.

[0034] The acceleration sensor is piezoelectric crystal, piezoresistive or capacitive.

Embodiment 2

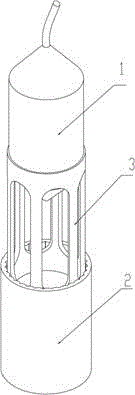

[0036] Such as Figure 2 to Figure 7 Shown is another embodiment of the present invention. It is different from Embodiment 1 in that: it also includes a sensor assembly bracket 3, the upper part of the sensor assembly bracket 3 is fixedly connected with the lower part of the sensor assembly 1, and the sensor assembly bracket 3 and the slip ring 2 are slidable socket.

[0037] The periphery of the sensor component bracket 3 is evenly distributed with hollows, and the lower part of the sensor component bracket 3 is provided with a limit buckle 5 matching with the upper component of the slip ring 2 .

[0038] The working principle of this embodiment is as follows: when the present invention is put into the liquid material, it falls at a constant speed through the traction line, and when the present invention is in normal fall or suspended in the liquid state, the slip ring 2 is suspended on the sensor assembly bracket by gravity 3, due to the function of the limit buckle 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com