Die coater and method for producing coating film

A technology of film coating and die coating, which is applied in the direction of devices and coatings for coating liquid on the surface, which can solve the problems of large film thickness deviation, changing structure, and inability to use coating width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0120] Hereinafter, examples are given and the present invention will be described in more detail, but the present invention is not limited to the following examples.

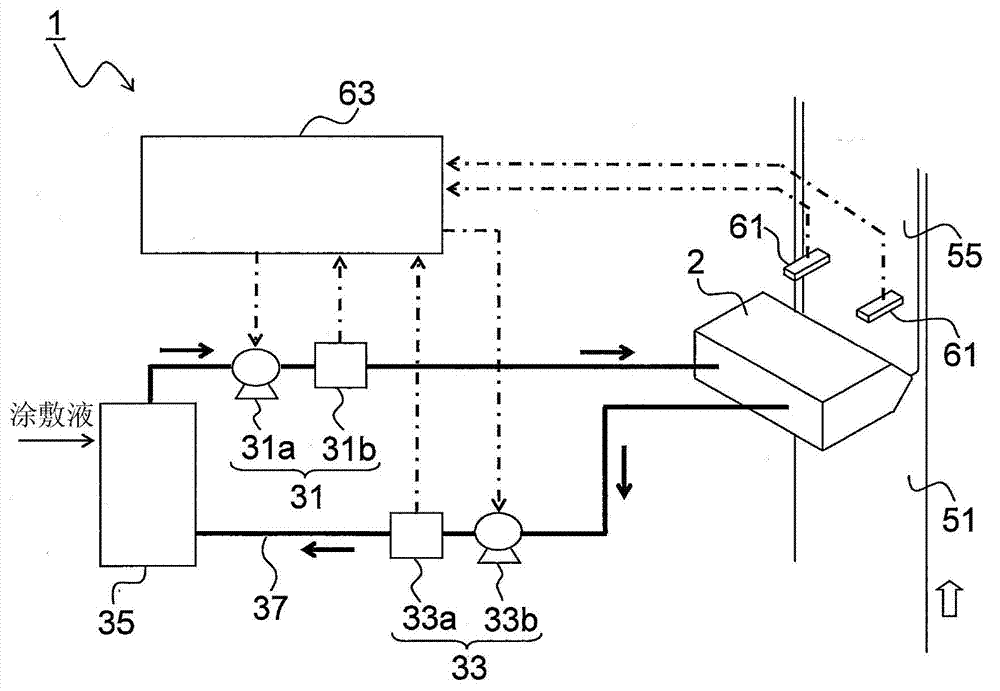

[0121] use with figure 1 The die coater shown is the same die coater as the Figure 6The manner shown also coats a substrate moving relative to the die coater. Moreover, the conveyance speed of a base material was set to 30 m / min, the temperature at the time of coating was set to 23 degreeC, and coating was performed so that the average film thickness of a coating film might become 23 micrometers.

[0122] A coating solution obtained by dissolving an acrylic adhesive in a mixed solution of toluene and ethyl acetate was used. The properties of this acrylic adhesive are as follows: using a rheometer (manufactured by HAAKE, レオストレス (Rheo Stress) RS1), under the condition of a temperature of 23° C. during coating, a shear rate of 20 (1 / s ) to 2000 (1 / s) to measure the viscosity of the acrylic adhesive, and the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com