Method for making ceramic electronic part, and plating bath

一种电子部件、制造方法的技术,应用在电容器制造、固定电容的零部件、电气元件等方向,能够解决Sn镀膜表面难包覆、电极可钎焊性下降等问题,达到稳定可钎焊性、可钎焊性改善、膜厚偏差降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, details of the present invention will be described based on specific embodiments and examples.

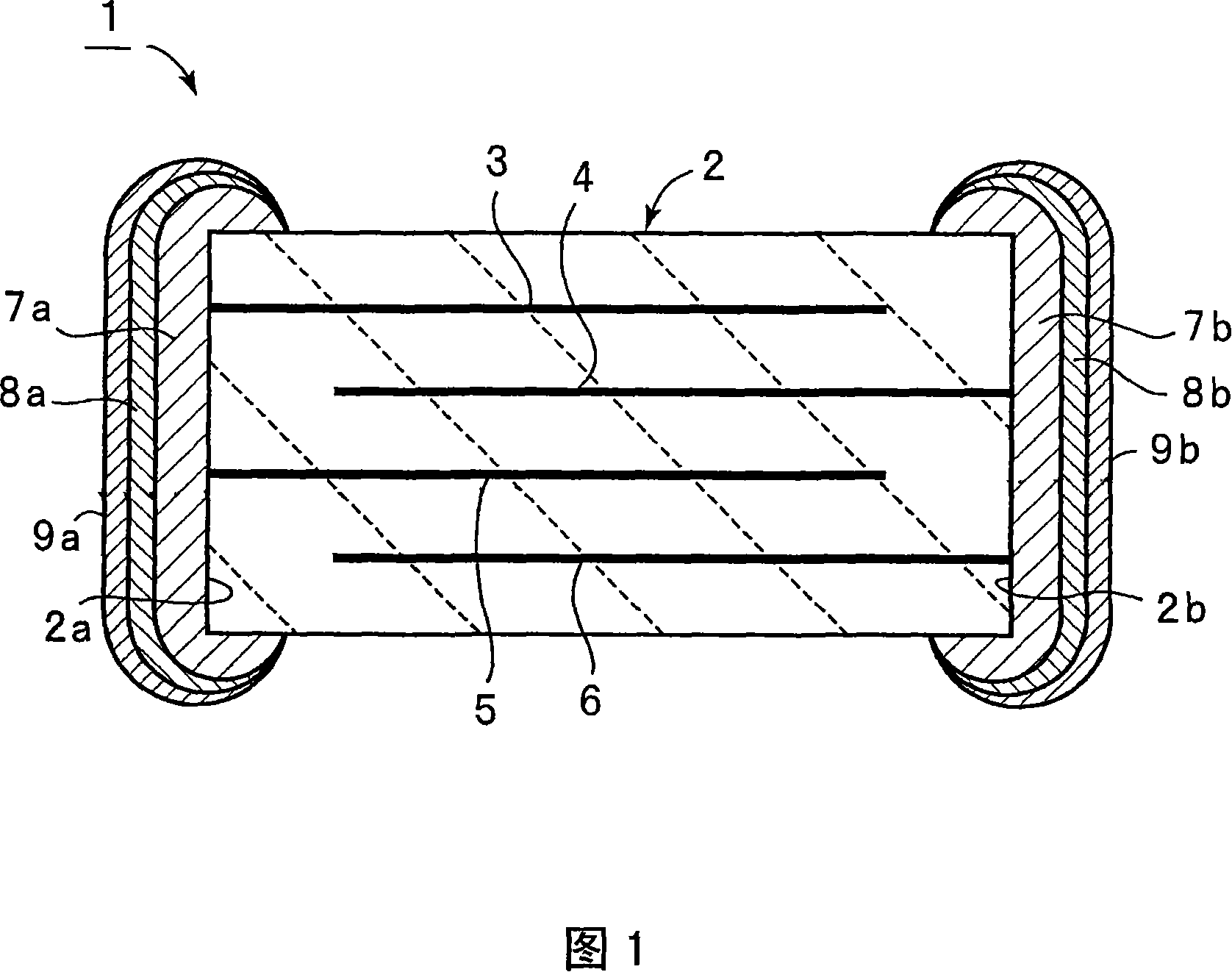

[0021] In the method of manufacturing a ceramic electronic component according to the present invention, first, an electronic component formed body composed of a ceramic containing Ba is prepared. Ba-containing ceramics are not particularly limited, but examples thereof include barium titanate-based dielectric ceramics, barium-aluminum-silica-based glass ceramics, and the like.

[0022] In addition, the above-mentioned electronic component formed body may be an electronic component formed body composed only of Ba-containing ceramics, or may be a laminated ceramic sintered body in which a plurality of internal electrodes are provided in Ba-containing ceramics.

[0023] In the present invention, after the electronic component forming body is prepared, an electrode having a Sn film is formed on the outer surface of the electronic component forming body. The struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com