Protection structure for hush pipe production

A technology for protecting structures and mufflers, which is applied in metal processing equipment, safety equipment, manufacturing tools, etc., can solve the problems of metal materials being ejected around, and achieve the effect of safe and efficient processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

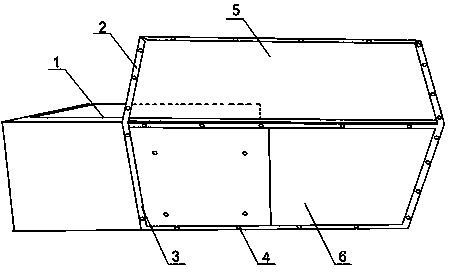

[0019] Such as figure 1 As shown, this embodiment includes an upper baffle and a lower baffle, the upper baffle and the lower baffle are connected by screws 4 , and the lower baffle is fixed on the external crimping machine 1 . The upper baffle and the lower baffle are connected, and a certain angle is formed between the two, so that it can more comprehensively protect the metal fragments ejected from all directions and endanger the construction personnel operating in the front; the lower baffle is fixed on the external crimping machine 1 , the bottom of the crimping machine 1 frame is fixedly connected with the lower baffle, which provides a safe operating environment for the construction personnel, and overcomes the defects that the construction personnel do not take safety protection measures or only take partial safety measures in the traditional crimping process, It is conducive to the safe and efficient operation of the process.

Embodiment 2

[0021] Such as figure 1 As shown, on the basis of Embodiment 1 in this embodiment, the upper baffle includes an upper frame 2 and an upper baffle glass 5, and the upper baffle glass 5 is fixed in the upper frame 2 by screws 4; the lower baffle It includes the lower frame 3 and the lower baffle glass 6 , the lower baffle glass 6 is fixed in the lower frame 3 by screws 4 , and the angle between the upper baffle and the lower baffle is 120o-150o. The set upper baffle glass 5 is transparent, which is convenient for construction personnel to observe the progress of the process. The connection between the upper baffle and the lower baffle is realized by welding the upper frame 2 and the lower frame 3. The screw 4 between the baffle glass and the baffle is connected Facilitate the installation and removal of the baffle glass.

[0022] The included angle between the upper baffle and the lower baffle is in the range of 120o to 150o, which is conducive to observing the progress of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com