Automatic feeding and discharging device

A technology of automatic loading and unloading and forehearth, applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of high labor intensity, dangerous grinding wheels, small production batches of medium and large bearing rings, etc., to reduce labor intensity, The effect of stable loading and unloading and avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

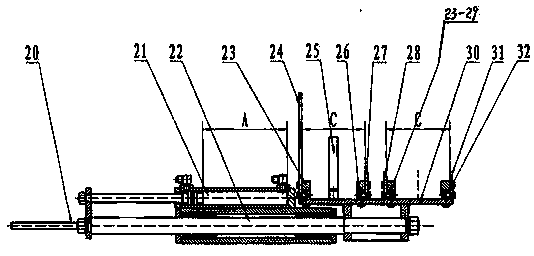

[0009] This technical solution is suitable for processing objects: bearing inner ring groove or bearing outer ring, processing range: diameter φ200mm to φ350mm, thickness: 50mm to 150mm, this technical solution is composed of upper and lower material channels, oil cylinder feeding and mechanical upper and lower The material consists of three parts.

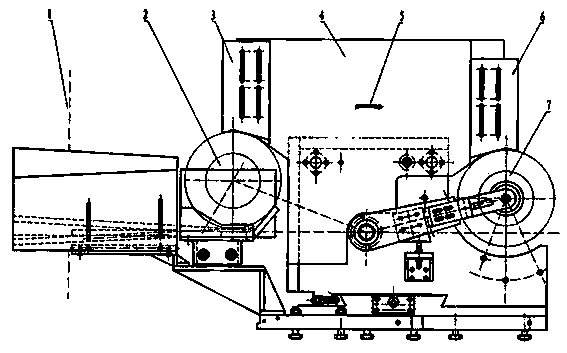

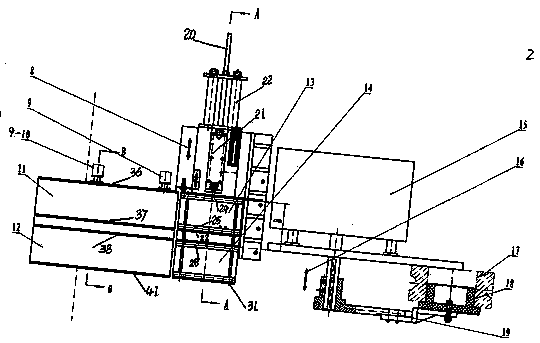

[0010] The boundary limit of the bed is equipped with a protective cover 1 near the upper and lower material channels, the panel 4 is fixed in front of the manipulator box 15, and the left and right transition plates 3 and 6 are installed on both sides of the panel, and the workpiece grinding position 7 is installed at the right end of the manipulator box. The dovetail guide rail on the manipulator box 15 matches the dovetail guide rail on the base and can move back and forth on the base. The dovetail guide rail on the base is connected to the bed with multiple T-slot screws fastening (see figure 1 ), a transmission shaft protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com