Super-plastic forming die and method thereof

A superplastic molding and mold technology, applied in the field of manufacturing, can solve the problems of inconsistent thickness uniformity of workpieces, reduction of mechanical properties of workpieces, increase of forming waste rate, etc., to prevent premature mold sticking in protected areas, low production cost and long production cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

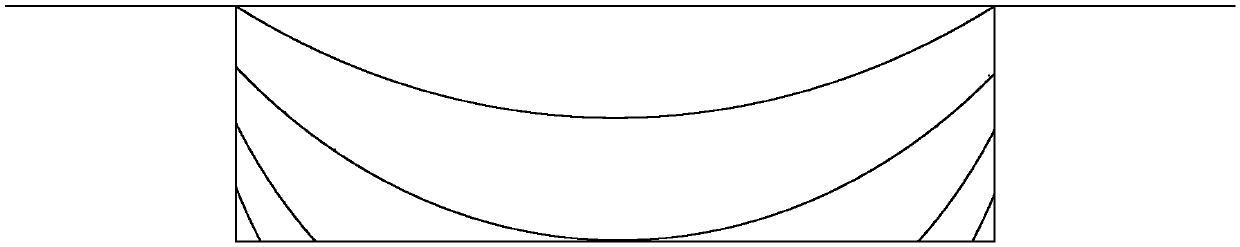

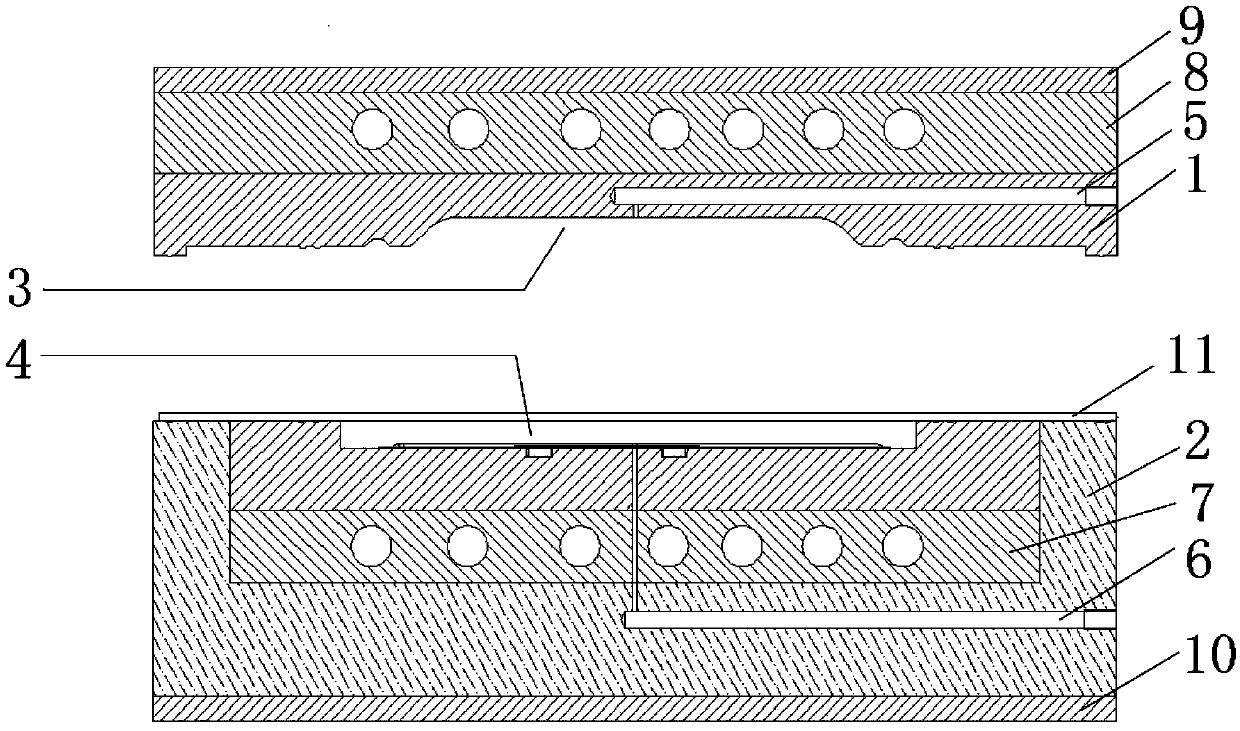

[0056] reference figure 2 with image 3 Optimize the design of the mold through calculation and simulation, and use the CNC lathe to manufacture the mold to realize that the amount required for the final workpiece can be preformed, and the preform cavity 3 of the upper mold 1 is designed and manufactured as image 3 The annular groove structure shown. The pre-formed structure is designed to improve the uniformity of the wall thickness of the part. When forming, the role of the annular groove is to thin the part that does not participate in the deformation after the normal superplastic forming, and increase its contribution to the uniformity of the forming After inflating downwards, the position of the plate 11 is exactly at the corner when it is pasted. Even if the pre-forming is not complete, the thickness of the pre-forming does not change, which just compensates for this deficiency and satisfies the overall wall thickness uniformity.

Embodiment 2

[0058] The following describes the molding process of using the mold described in Example 1, using 5083 aluminum alloy sheet with a thickness of 1 mm as raw materials, and adopting superplastic inflating technology to prepare a box-shaped electronic housing product.

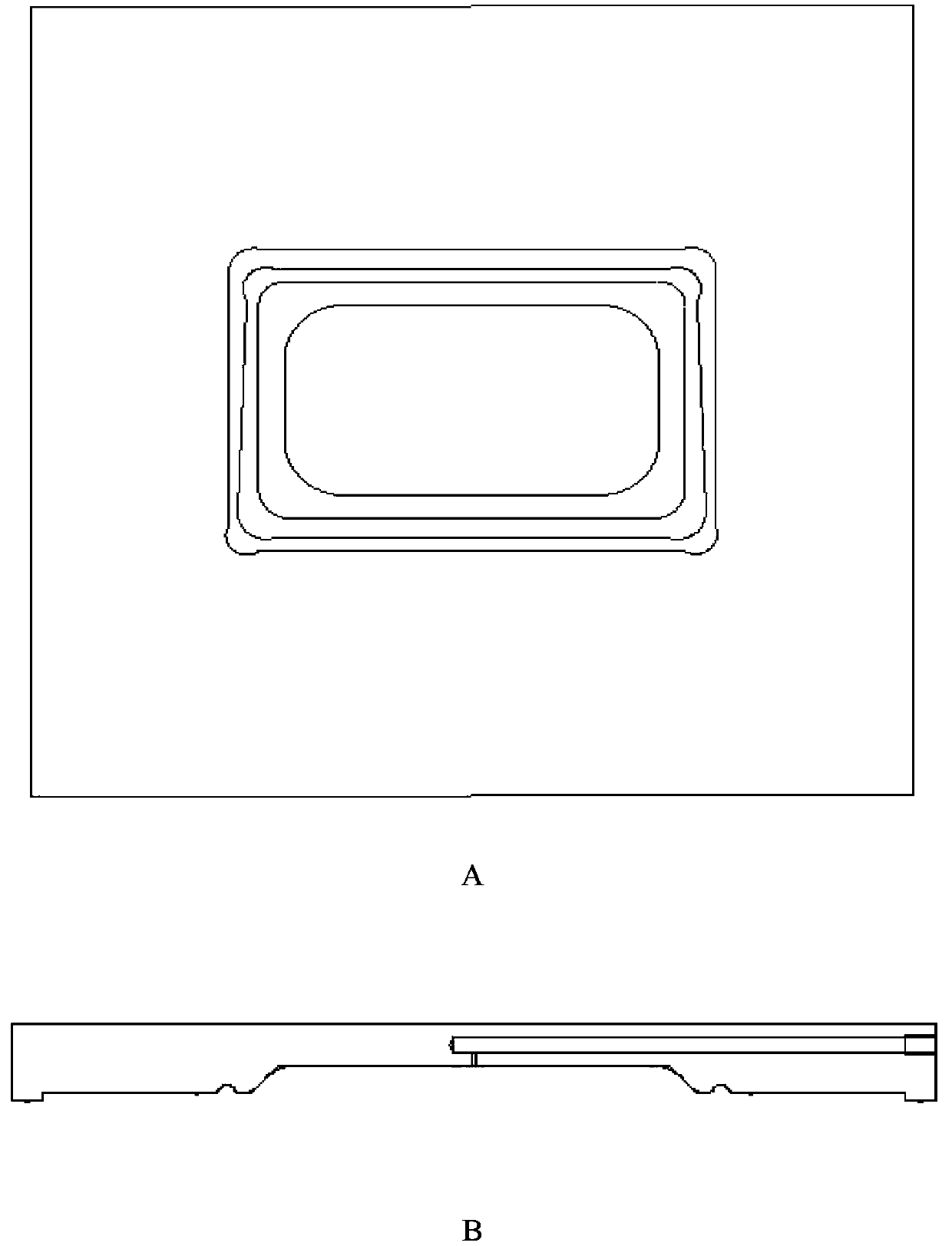

[0059] reference figure 2 with Figure 4 , First heat the mold, and place the plate 11 on the forming cavity 4 after 350-600 degrees Celsius. With the action of a hydraulic press, the upper mold 1 and the lower mold 2 are closed and sealed, and 0.1-1 MPa gas is introduced through the lower air inlet 6 , The plate 11 is gradually deformed under the gas pressure, and finally fits with the pre-formed cavity 3 of the upper mold 1, and then 0.4-5MPa gas is introduced through the upper air inlet 5, so that the plate 11 is deformed downwards, and finally meets the forming cavity 4. Fit and take out the parts after forming.

[0060] Results: The thickness at the corners reached 0.7~0.9mm, and the thickness uniformity of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com