Lime calciner paint liner and forming method thereof

A calciner and coating technology, applied in the field of lime calciner lining body and its molding, can solve the problems of difficult construction quality assurance, troublesome repair work, long construction period, etc., and achieve simple molding method, efficient molding quality, and improved quality and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

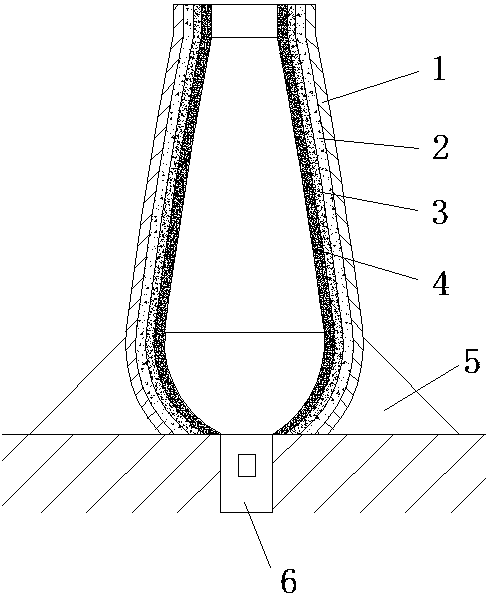

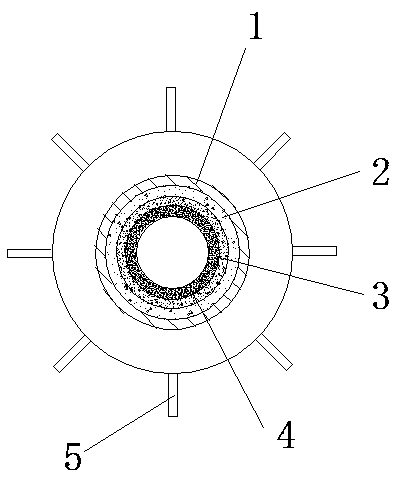

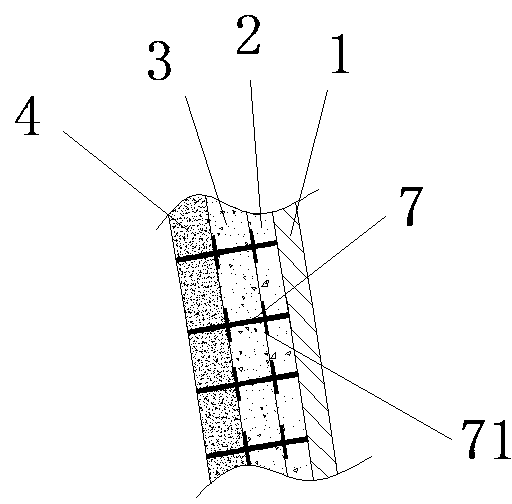

[0027] Embodiment 1, a kind of lime calcination furnace, furnace body is in the shape of a vase with a big middle and two small ends, with a height of 17m. The furnace body is in the shape of a vase with a maximum inner diameter of 6m. The outer periphery of the steel plate shell 1 is provided with reinforcing gussets 5, and the inner wall of the shell 1 is uniformly welded with a number of paint anchors 7 made of radial and steel bars. The length of the paint anchors is slightly smaller than the total thickness of the lining body of the lime calciner. In the length direction of the paint anchor, a marker 71 is provided corresponding to the thickness of the thermal insulation layer and the intermediate lining layer. The marker 71 of this embodiment is a connecting short rod perpendicular to the axial direction of the paint anchor 7, and the bottom of the furnace body is provided with The combustion chamber 6 communicated with the inner cavity of the furnace; the inner lining ...

Embodiment 2

[0035] Embodiment 2, a lime calcination furnace, the furnace body is in the shape of a vase with a large center and two small ends, with a height of 15m and a maximum inner diameter of 5m. Its overall structure is the same as that of Embodiment 1. And the coating formula of the thermal insulation coating layer 2 of the present embodiment, its composition and composition ratio by weight percentage are: the 80 bauxite 19.5 that particle size is 10~5mm, the 80 bauxite 12 that particle size is 5~3mm, the particle size is 80 bauxite 11 with a particle size of 3 to 1 mm, 80 bauxite with a particle size of less than 1 mm 7, expanded perlite 15, kyanite 3 with a particle size of 1 mm or less, 200 mesh 88 bauxite 16.67, microsilica powder 5, pure calcium aluminate cement 10. Organic explosion-proof fiber 0.03, sodium tripolyphosphate 0.2, hydroxyethyl cellulose (HEC) 0.6; the coating formula of the intermediate lining coating layer 3, its composition and composition ratio by weight pe...

Embodiment 3

[0038] Example 3, a lime calciner, the furnace body is in the shape of a vase with a large middle and two small ends, with a height of 13m and a maximum inner diameter of 4m. A number of radial paint anchors 7 on the inner wall of the housing 1 and markers 71 corresponding to the thickness of the thermal insulation layer and the intermediate liner in the length direction of the paint anchors are ceramic products. The inner lining is composed of a thermal insulation coating layer 2 , an intermediate lining coating layer 3 and a working coating layer 4 , wherein the outer wall of the thermal insulation coating layer 2 is closely attached to the inner wall of the shell 1 . The coating formula of the thermal insulation coating layer 2 in this embodiment, its constituents and composition ratio by weight percentage are: 80 alumina 20 with a particle size of 10-5 mm, 80 alumina 11.0 with a particle size of 5-3 mm, and a particle size of 3 ~1mm 80 bauxite 10.0, 80 bauxite with parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com