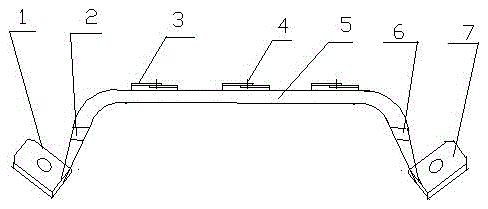

The structure of the automobile fuel tank strap

A technology for automotive fuel tanks and straps, which is applied to vehicle components, the arrangement combined with the fuel supply of internal combustion engines, power devices, etc., and can solve problems such as fuel tank safety hazards, low installation efficiency, and corrosion of fuel tank straps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Below in conjunction with accompanying drawing, the present invention will be further described;

[0007] The structure of the automobile fuel tank strap includes a bayonet plate A1 and a bayonet joint A2, and is characterized in that: the two ends of the strap body 5 are respectively provided with a bayonet joint A2 and a bayonet joint B6; The bayonet plate A1 is connected; the bayonet joint B6 is connected with the bayonet plate B7; the upper surface of the strap body 5 is uniformly provided with several adjustment devices; the adjustment device is composed of two symmetrical It consists of oppositely arranged steel reinforcements 3 and fastening screws 4; the steel reinforcements 3 are provided with elongated grooves. As can be seen from the accompanying drawings, the fuel tank strap uses two ends of the strap body to wrap around and fix the bayonet joint. The bayonet joint is integrally cast with the bayonet plate. Because the bayonet hole is a T-shaped slot, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com