Electric worm driving mechanism of electric-control mechanical-type automatic speed changer

A technology of automatic transmission and driving mechanism, which is applied in the direction of mechanical equipment, components with teeth, transmission device control, etc. It can solve the problems of high processing cost, easy to touch the beam, and long size of gear shifting, and achieve a reasonable and compact space layout. , Not easy to get stuck, easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further illustrate the structure and function of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments, but it should be understood that the protection scope of the present invention is not limited by specific embodiments.

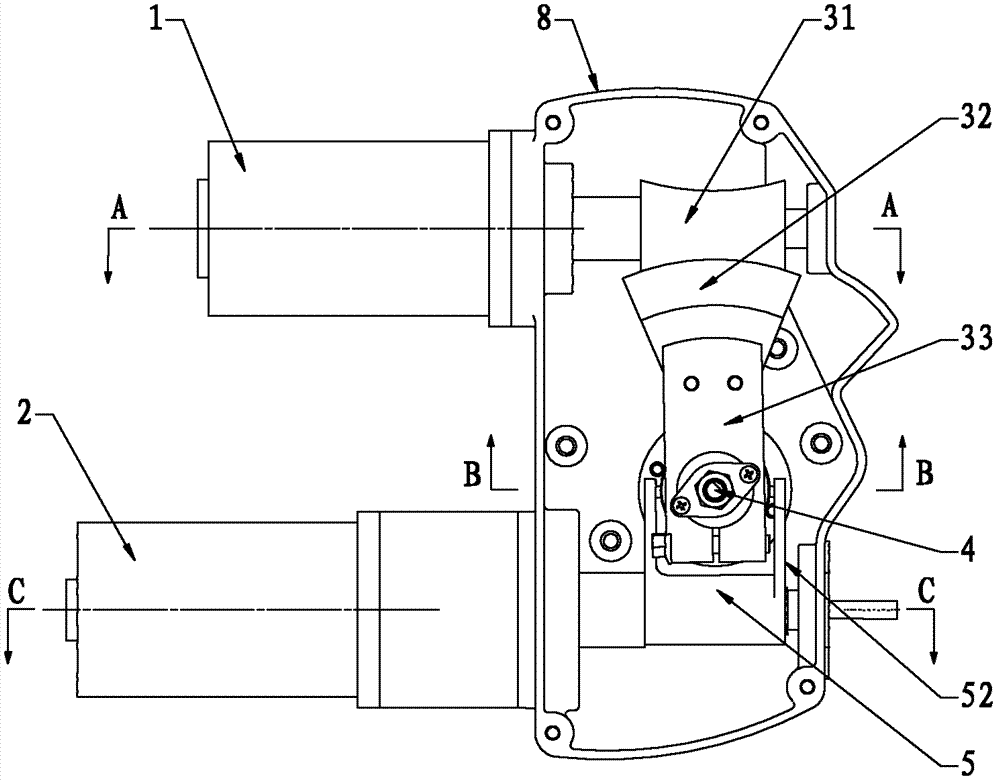

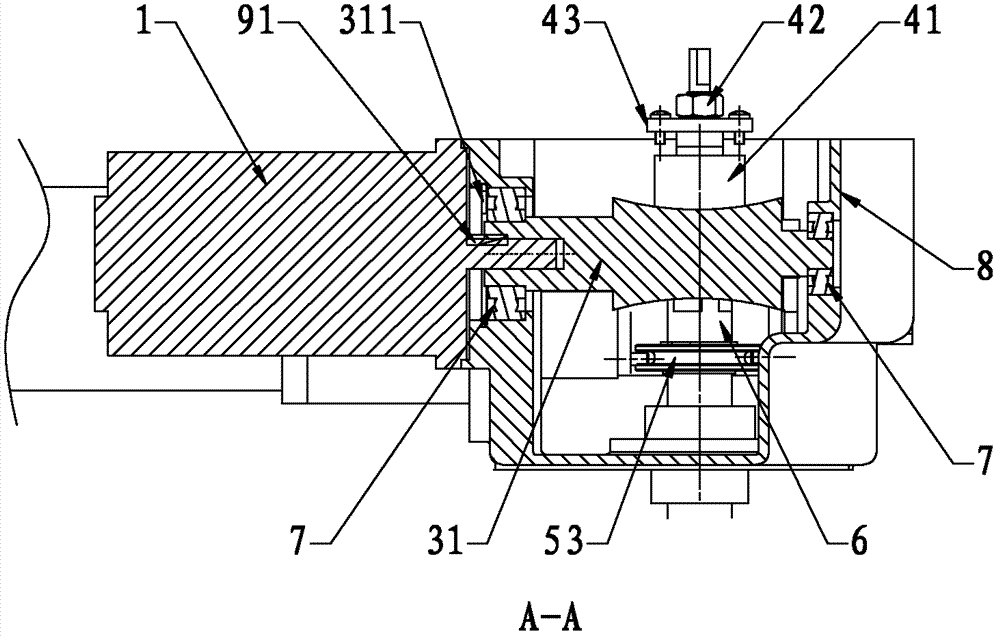

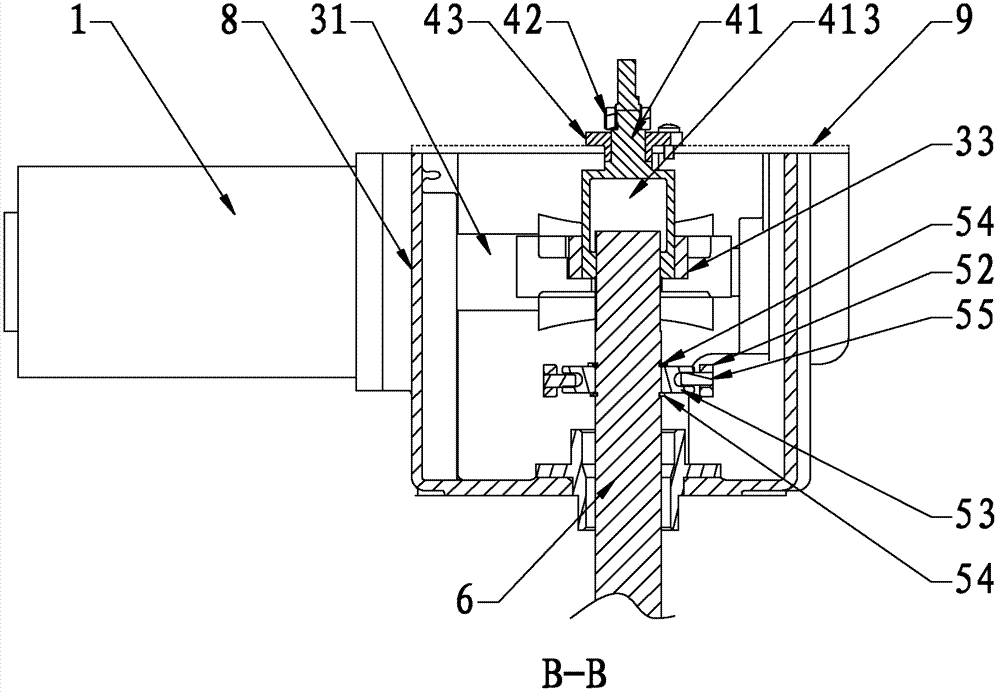

[0044] Such as Figure 1 to Figure 8 As shown, the present embodiment is an electric worm drive mechanism of an electronically controlled mechanical automatic transmission, which is arranged on the top of the gearbox, and it includes a casing, a shift shaft 6, a gear selection motor 2, a gear shift motor 1, and a gear shift assembly 4 and file selection component 5. The casing is composed of a box-shaped casing 8 and a cover plate 9; the shift motor 1 and the gear selection motor 2 are horizontally arranged on the side wall of the casing 8, and are respectively used to drive the shift shaft 6 along the circumferential direction. Rotate and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com